Unique training for professionals

AXYS FORMATION is an accredited training center, specializing in the delivery of tribology training. in the field of tribology.

OUR STRENGTHS :

REQUIREMENT ADAPTABILITY TRAINING PORTFOLIO TREE HIGH QUALIFICATIONS

How do we respond to customer requests?

We deliver comprehensive training courses, both face-to-face and online.

AT THE EXPERT

We offer comprehensive classroom programs leading to 18346 -4-5 certification, as well as specific programs to meet your current requirements. Our high level of in-house expertise means we can meet all your requirements.

AT HOME AND EVERYWHERE

What's more, we deliver complete training courses online, so you can access them whenever and wherever you want. We're not talking about a simple training course that records a presentation by a trainer. No, we offer a complete package that lets you track your progress in real time, so you can come back to it whenever you like and measure your progress in a fun, professional way.

LEVELS I TERRAIN

Acquisitions :

- in-depth, cross-disciplinary knowledge of the world of tribology

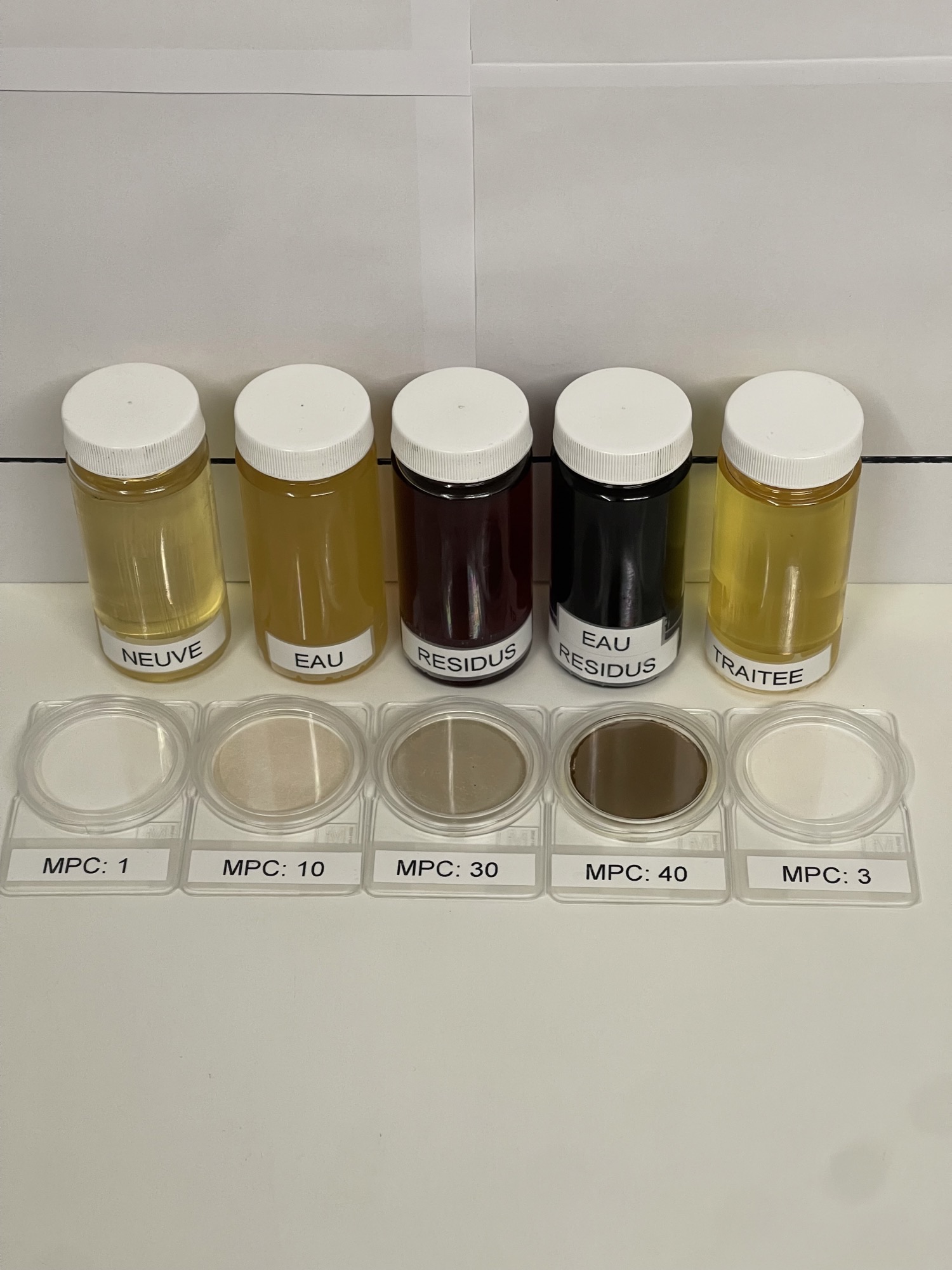

- Approach to lubricants, their use and inspection

- Maintenance capabilities of devices and associated equipment

- Set up sample-measuring equipment, and know how to use portable instruments with the right intervals

- Controls the sending of raw data

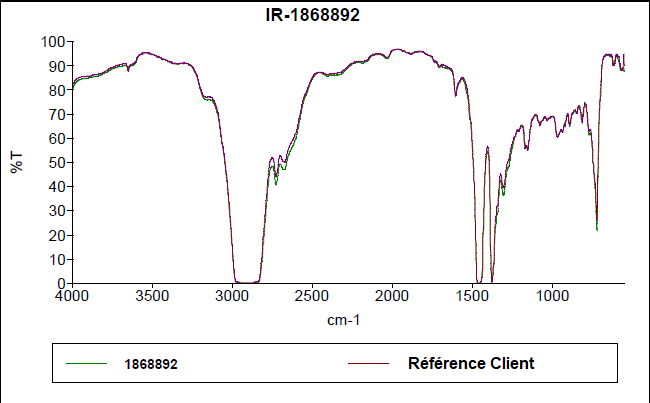

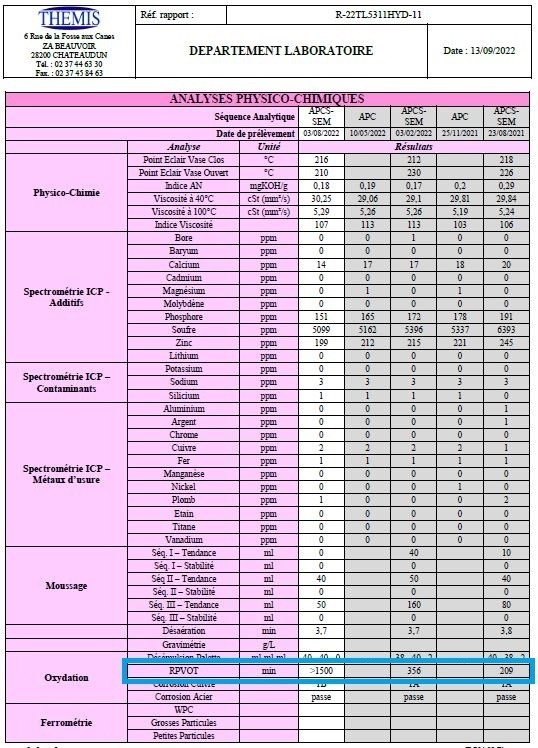

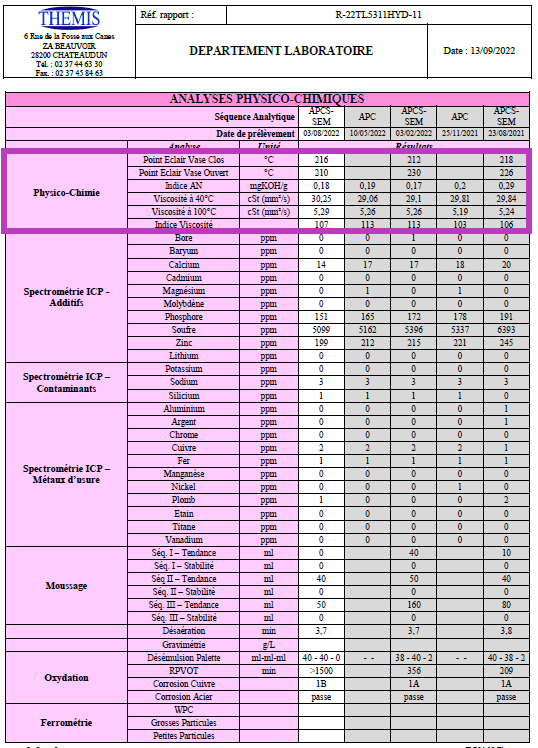

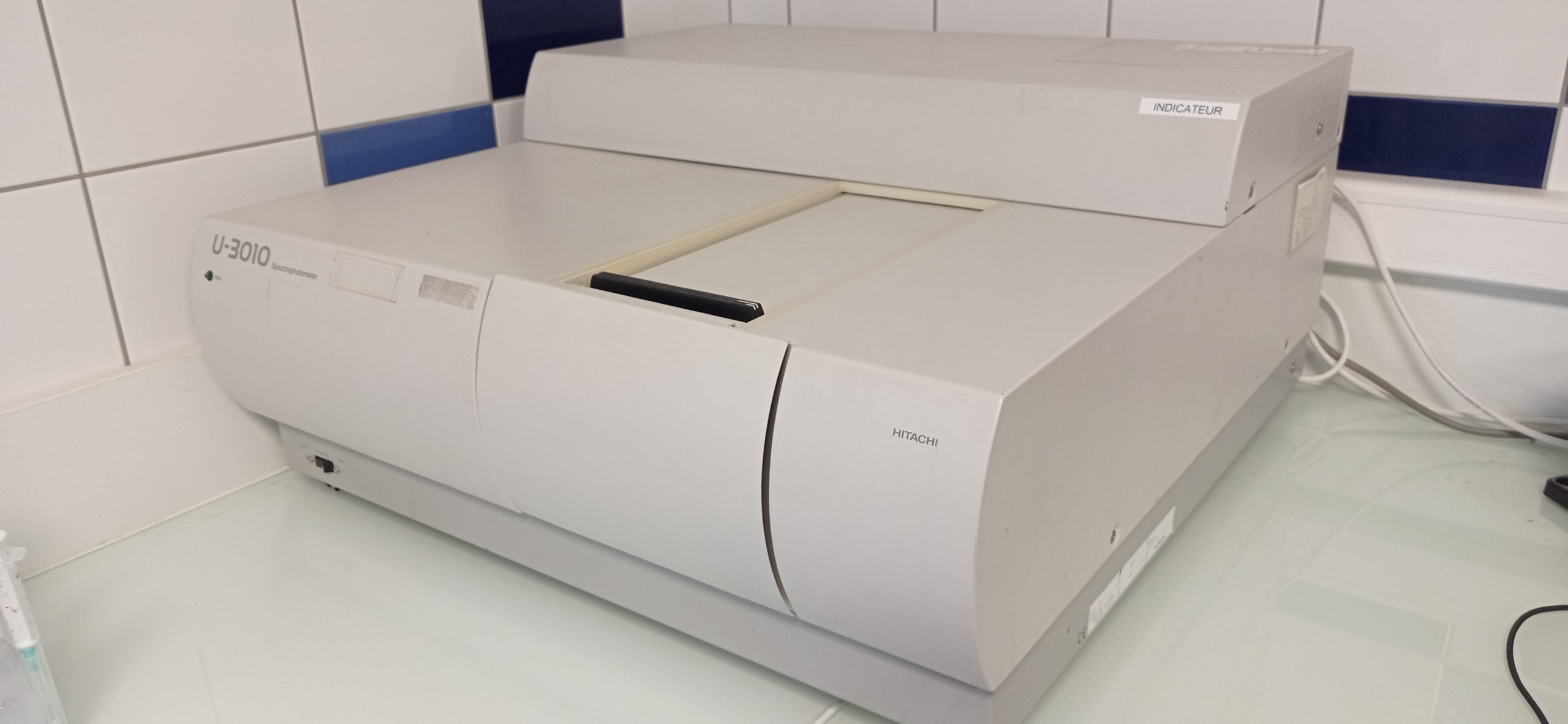

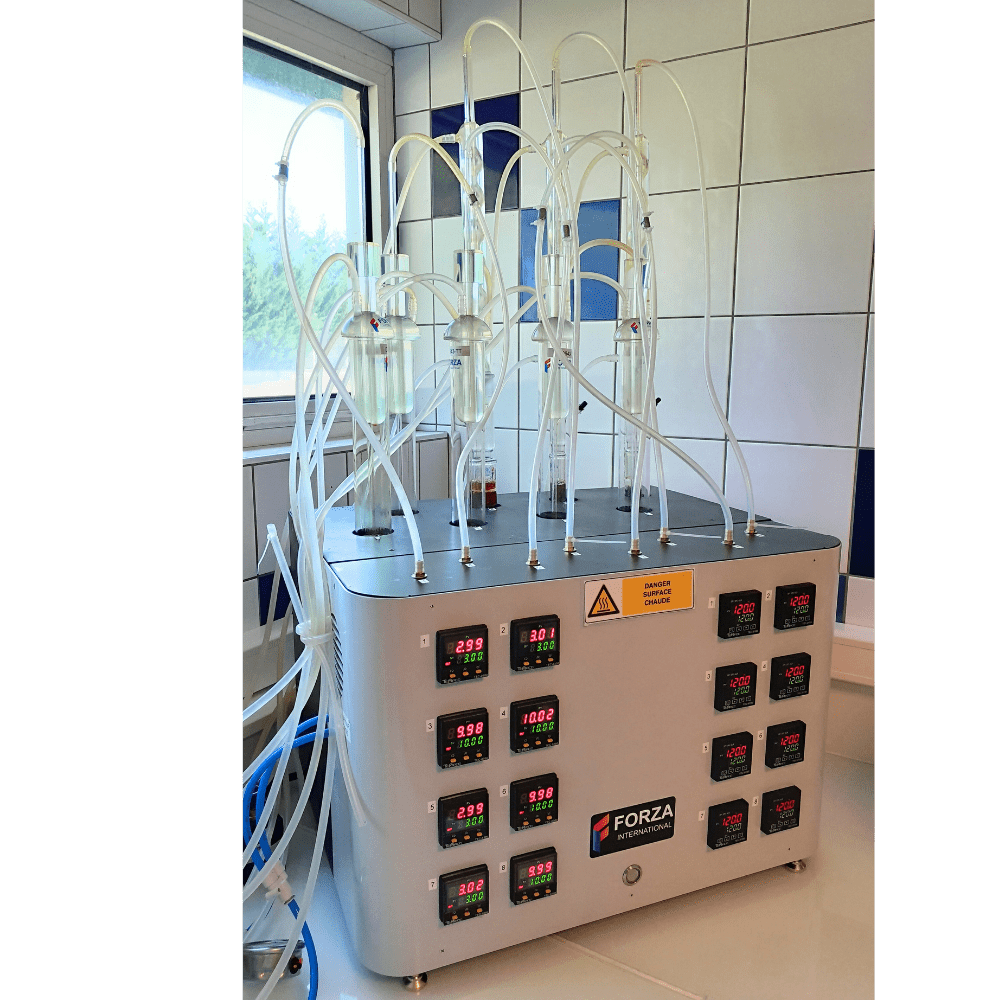

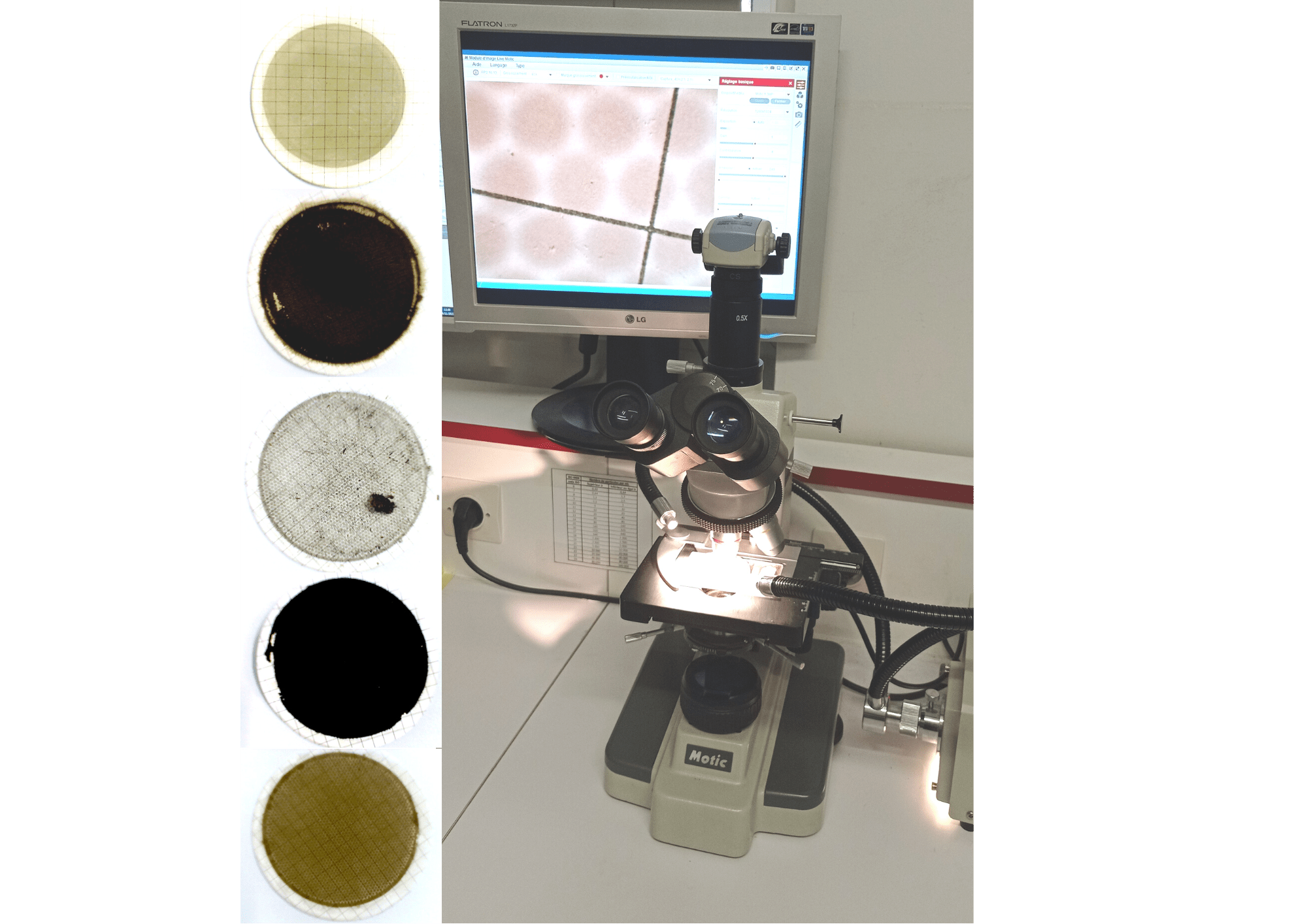

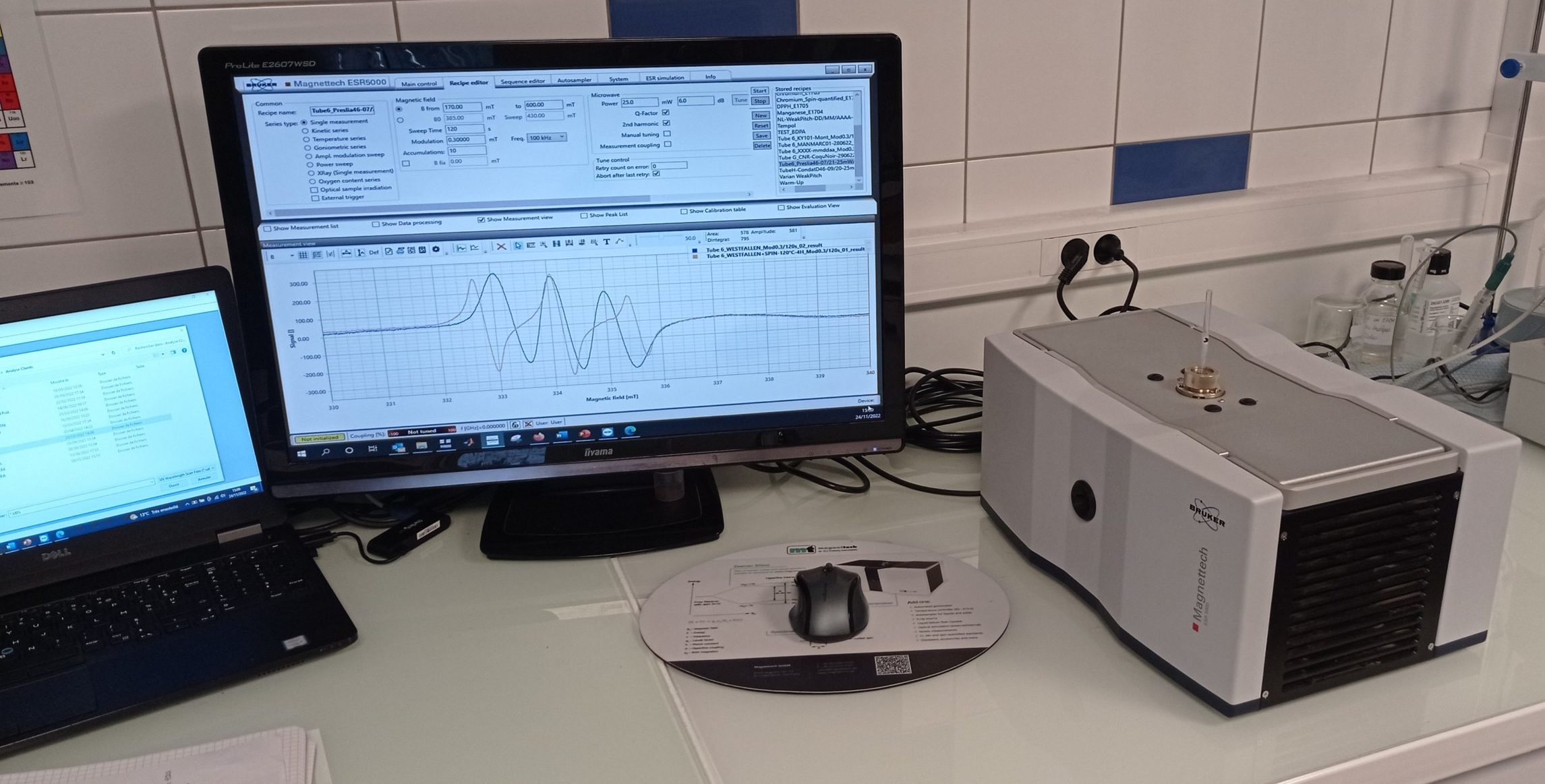

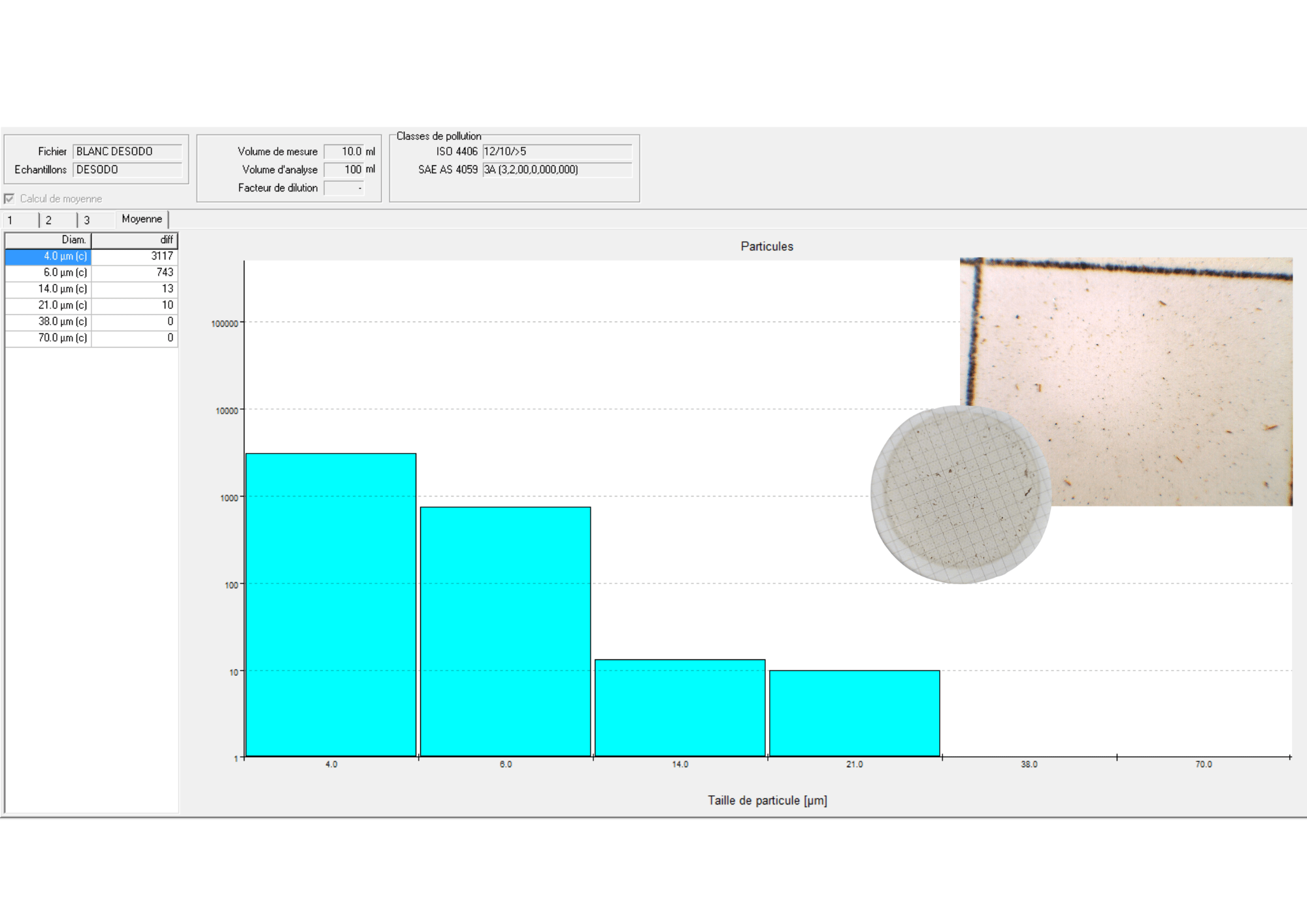

LEVEL II TESTING AND ANALYSIS

Acquisitions :

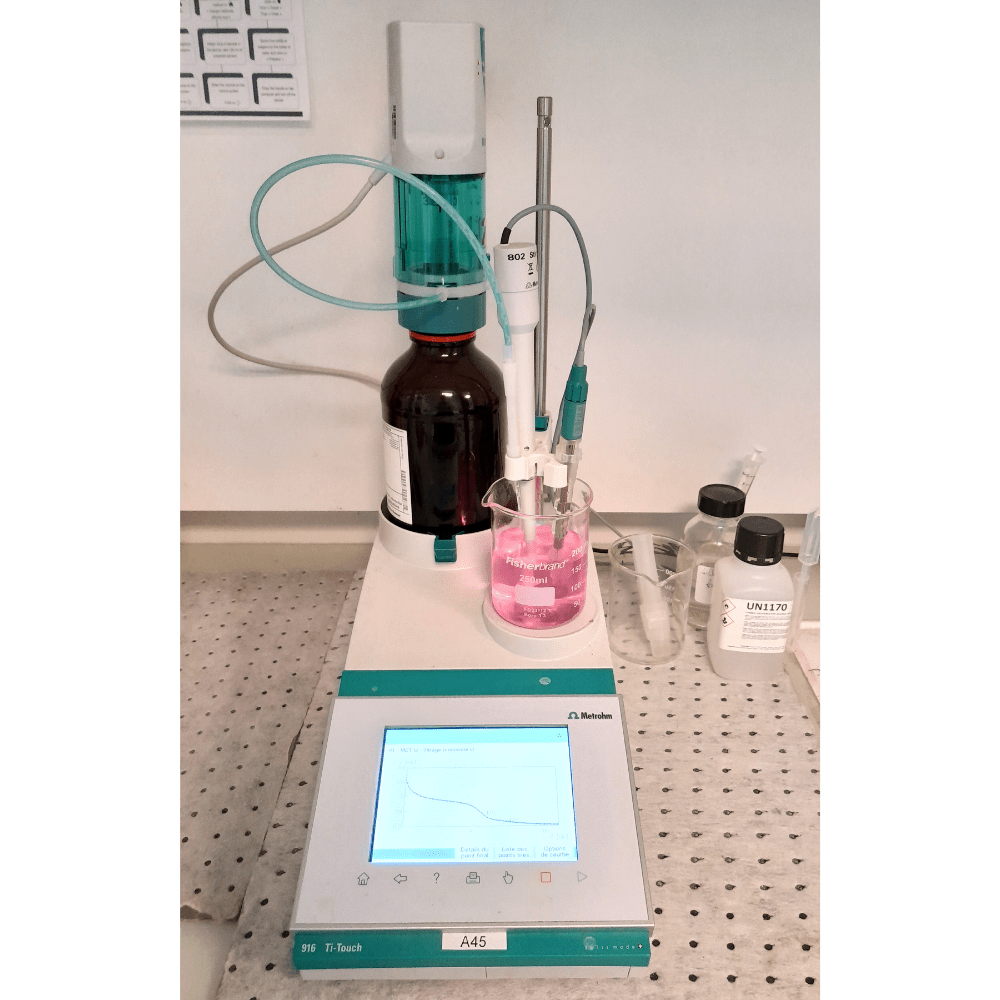

- Configure instruments for basic tests

- Instrument calibration

- Establish procedures for sampling, preparation, transport, selection of locations, methods, equipment and installation supervision.

-Apply test methods and sort results according to specifications and operating procedures.

-Link with the laboratory

-Acquire basic analysis techniques, know how to prepare reports, give recommendations, improvements, corrective actions and manage associated databases.

-Master the use of lubricant monitoring technologies

- Know how to give guidelines to field personnelconfigure instruments for basic tests

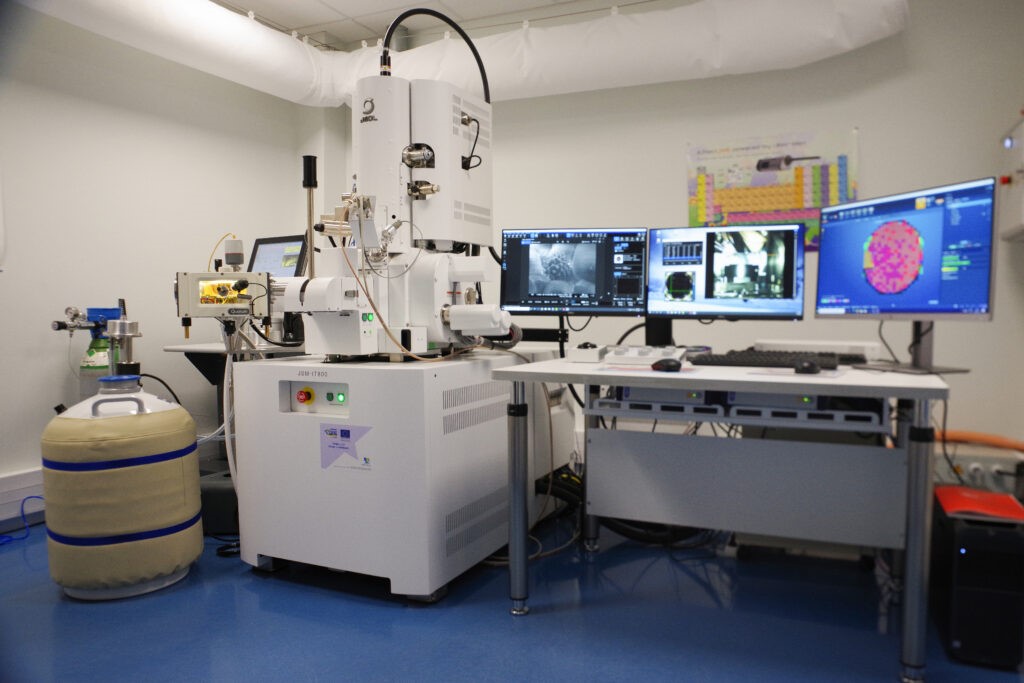

LEVEL III EXPERT

Acquisitions :

-Mastery of the interpretation of test methods, standards, codes, specifications and operating procedures

- Choice of analysis technique for different machines

-Establish route plans, monitoring and quality programs

-Establish alarm levels, targets and machine limits

-Manage and interpret results in depth, analyze failure modes, their effects and critical levels.

-Able to put forward specifications for new monitoring modes

-Make in-depth recommendations and guide or identify lubricant improvements

-Evaluate the influence of different chemical and physical properties on all systems involved in lubrication.

-Guide and structure the work of the other 2 levels, and evaluate budgetary approaches.