Practicality

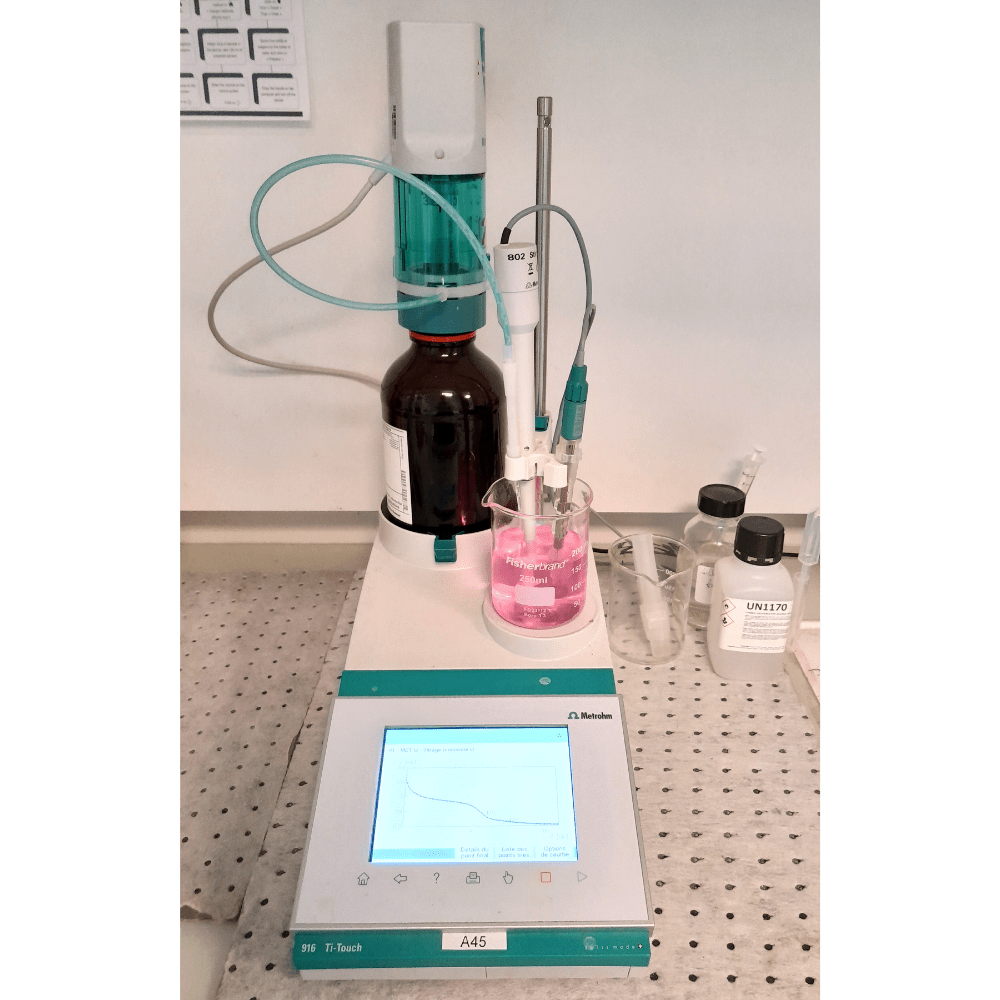

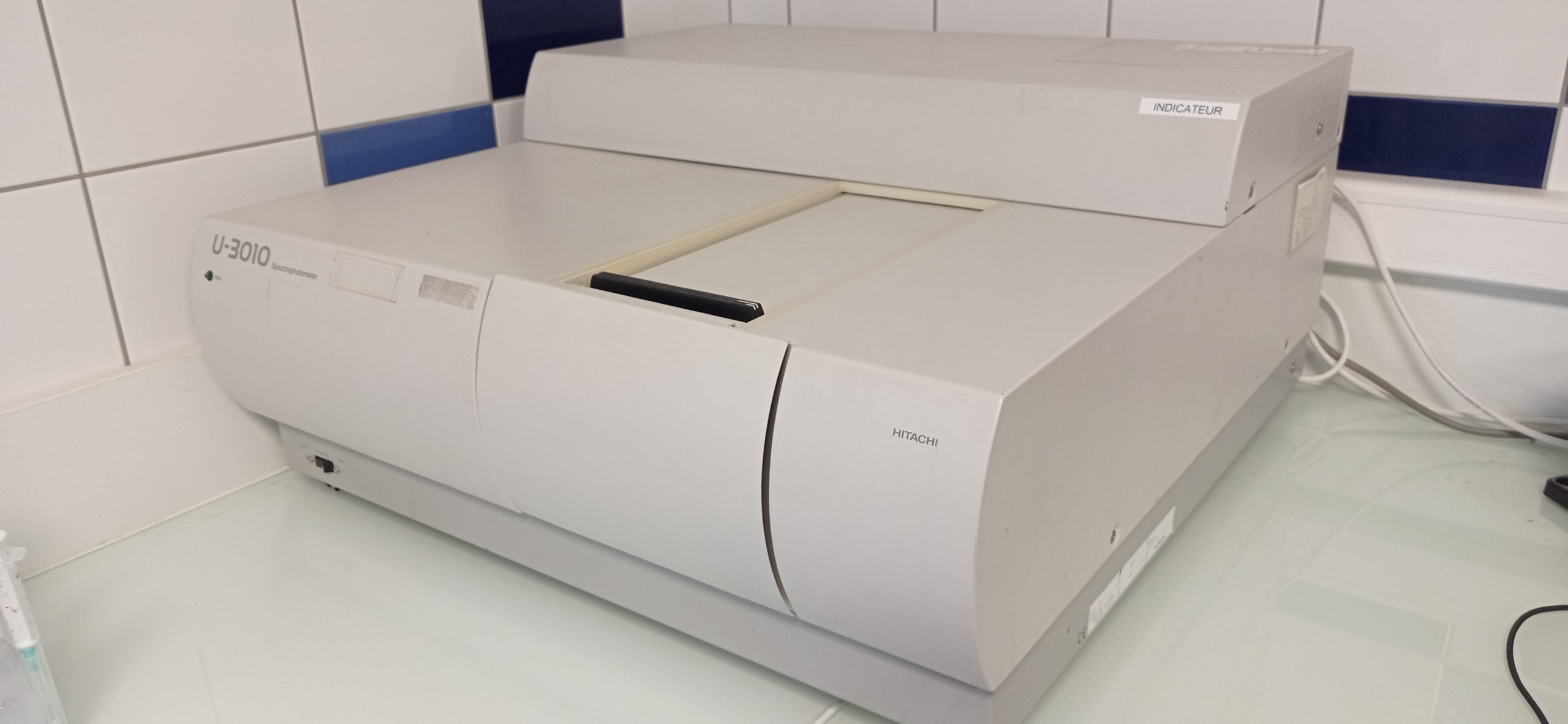

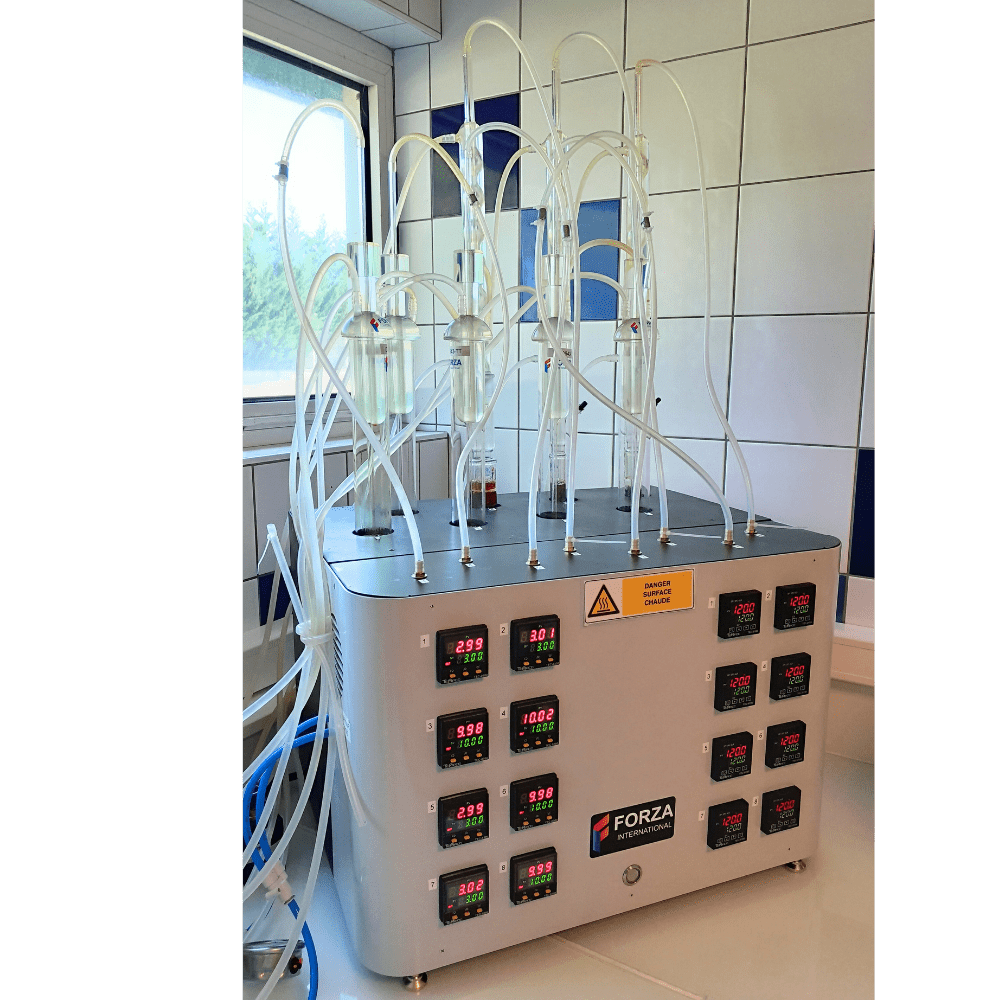

Compact, lightweight, and robust, it easily adapts to industrial environments and laboratories.

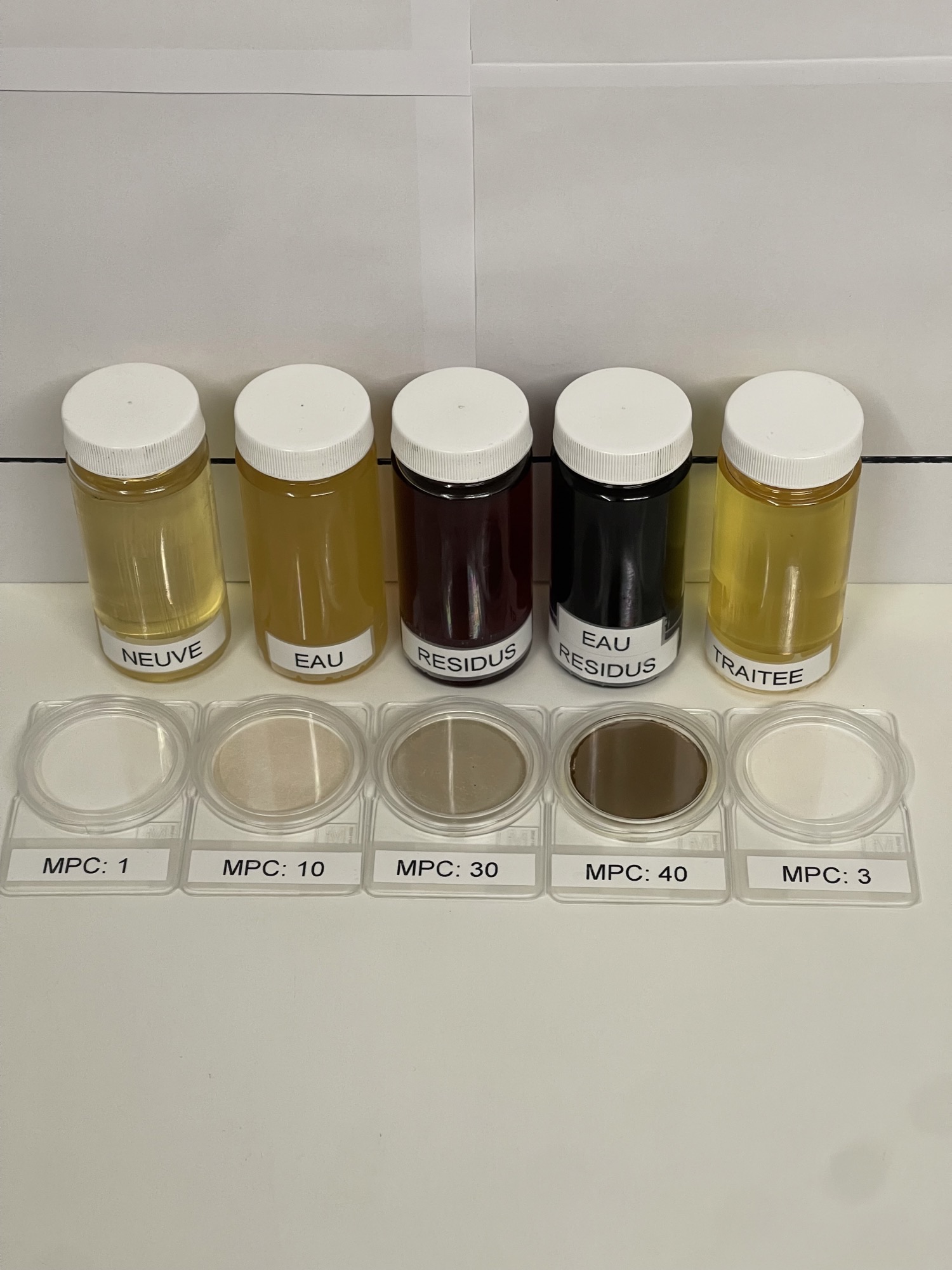

Versatility

Compatible with oils, lubricants, fuels, and hydraulic fluids up to 1000 cSt.

Advantage

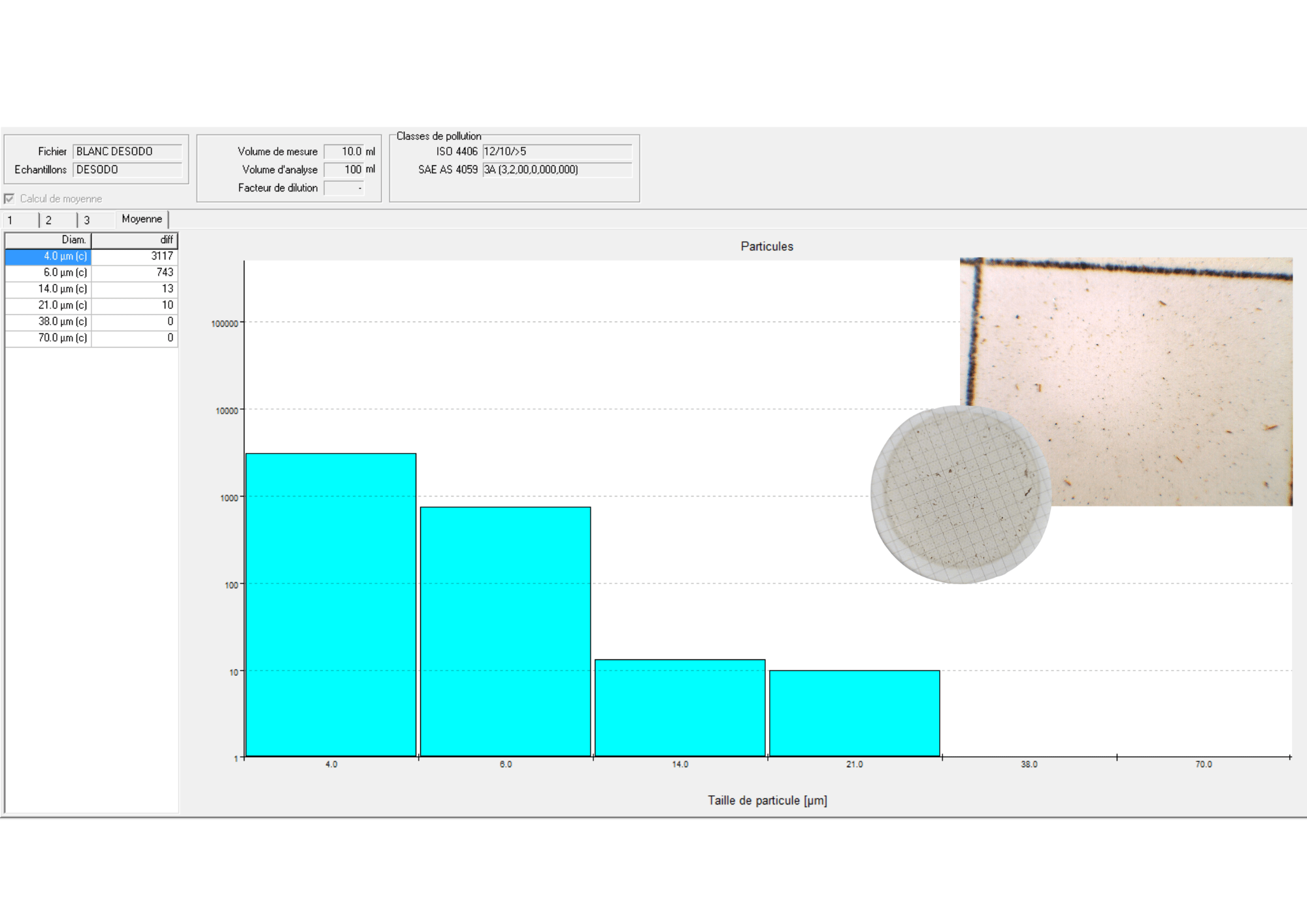

Automatic adjustment of analysis speed according to fluid properties.

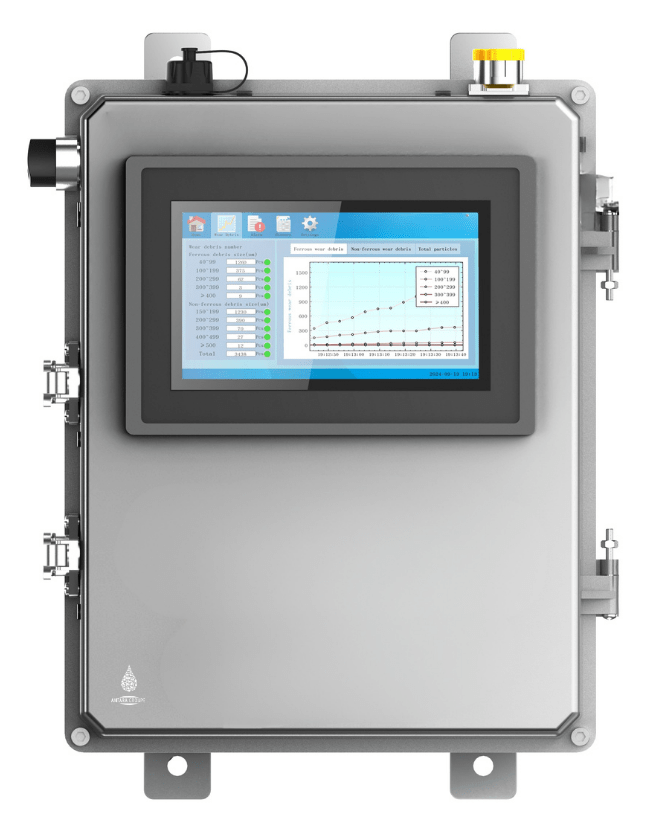

Precision & Reliability

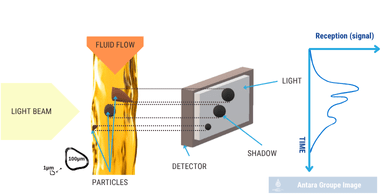

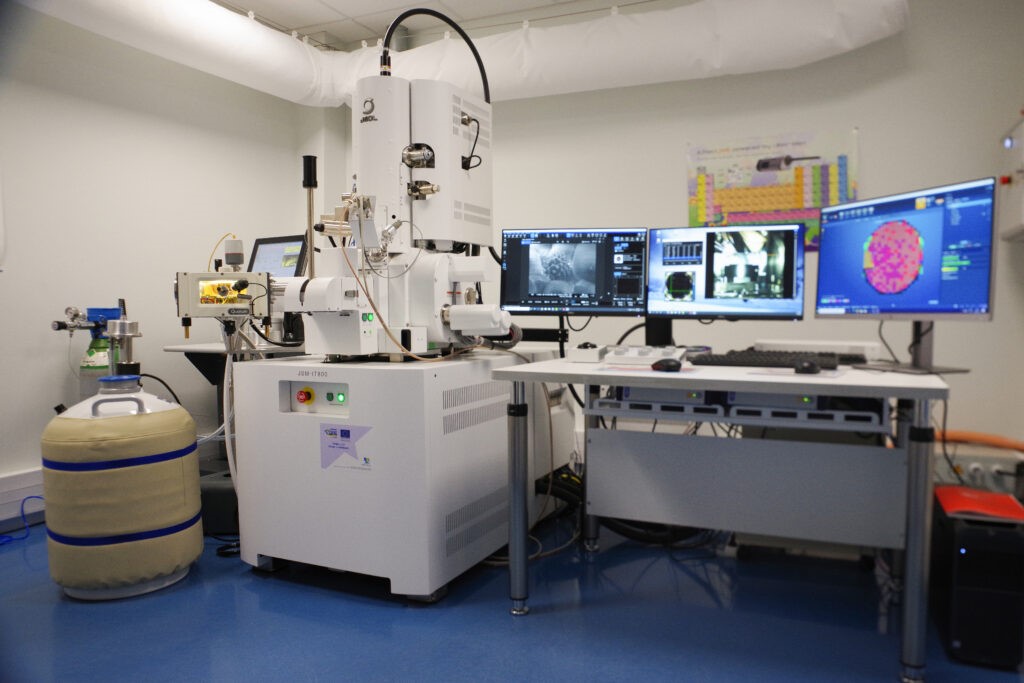

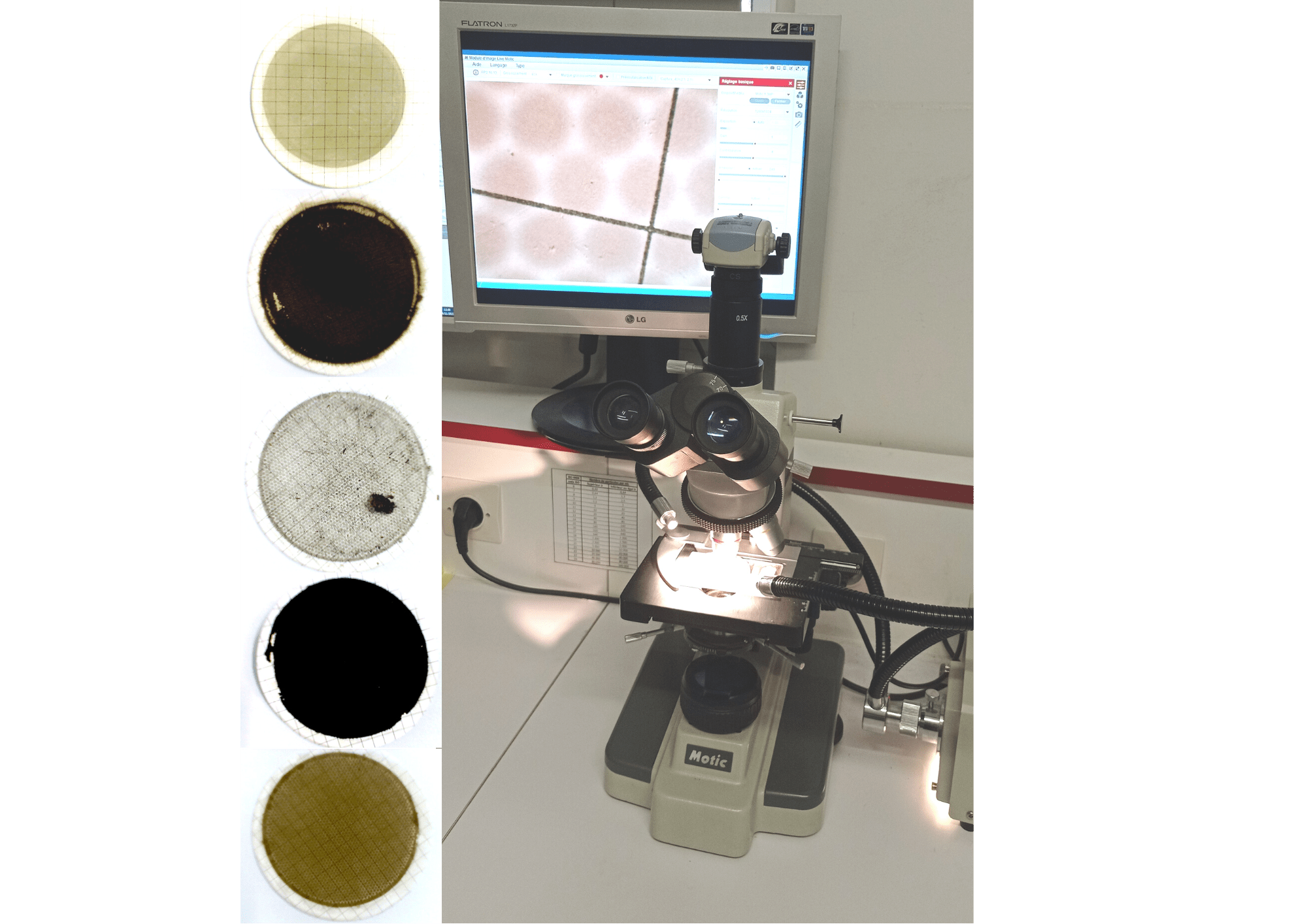

Particle measurement from 1 to 100 µm with a counting accuracy of 2.5% coincidence (±3% on the sample volume)

Automated sampling of the fluid.

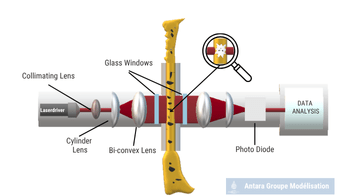

Automated sampling of the fluid. Laser analysis and particle classification.

Laser analysis and particle classification. Instant display of results on screen.

Instant display of results on screen. Storage and transfer of data for in-depth analysis.

Storage and transfer of data for in-depth analysis.