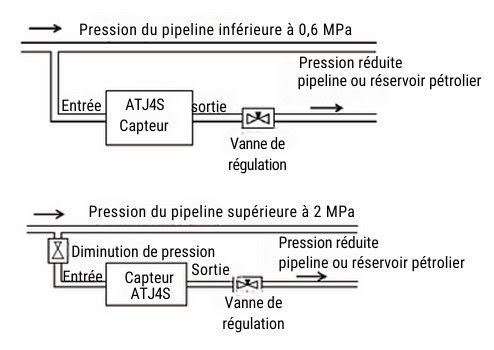

Installation

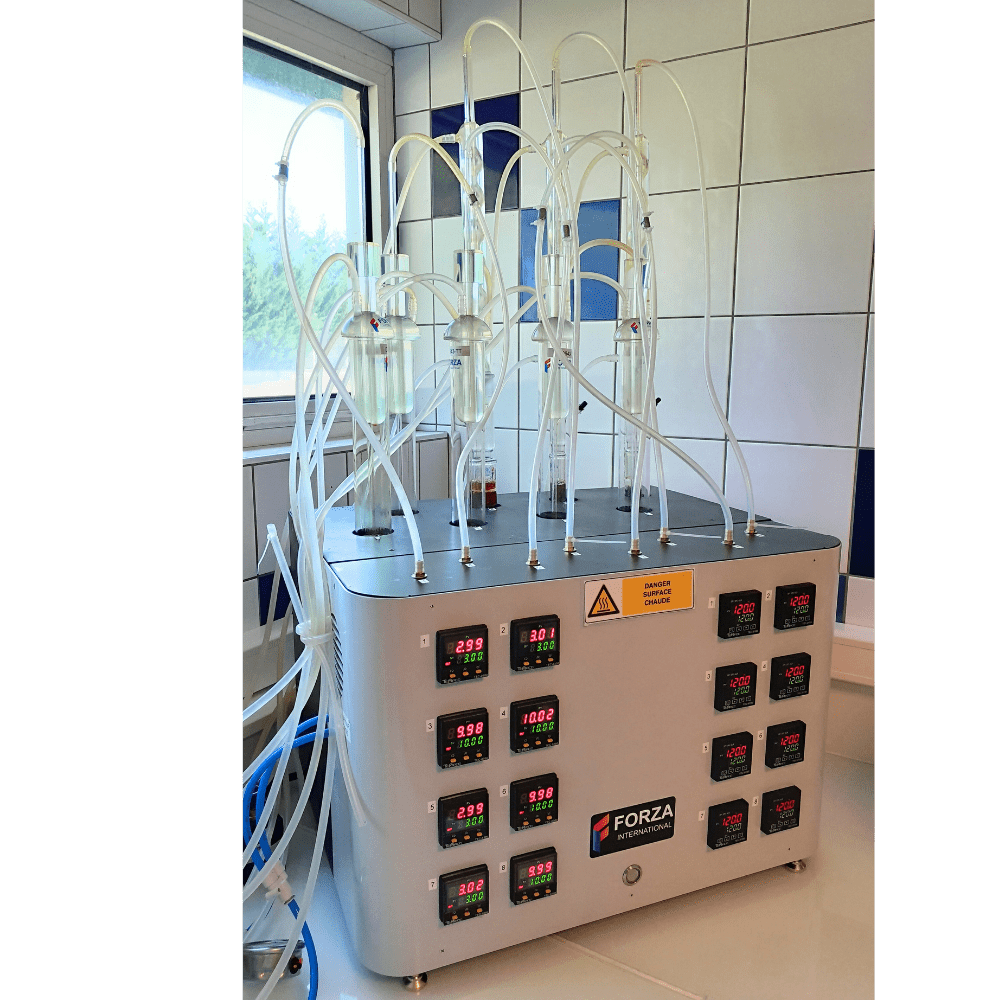

Easy integration into high-pressure hydraulic systems (up to 400 bar with pressure relief valve).

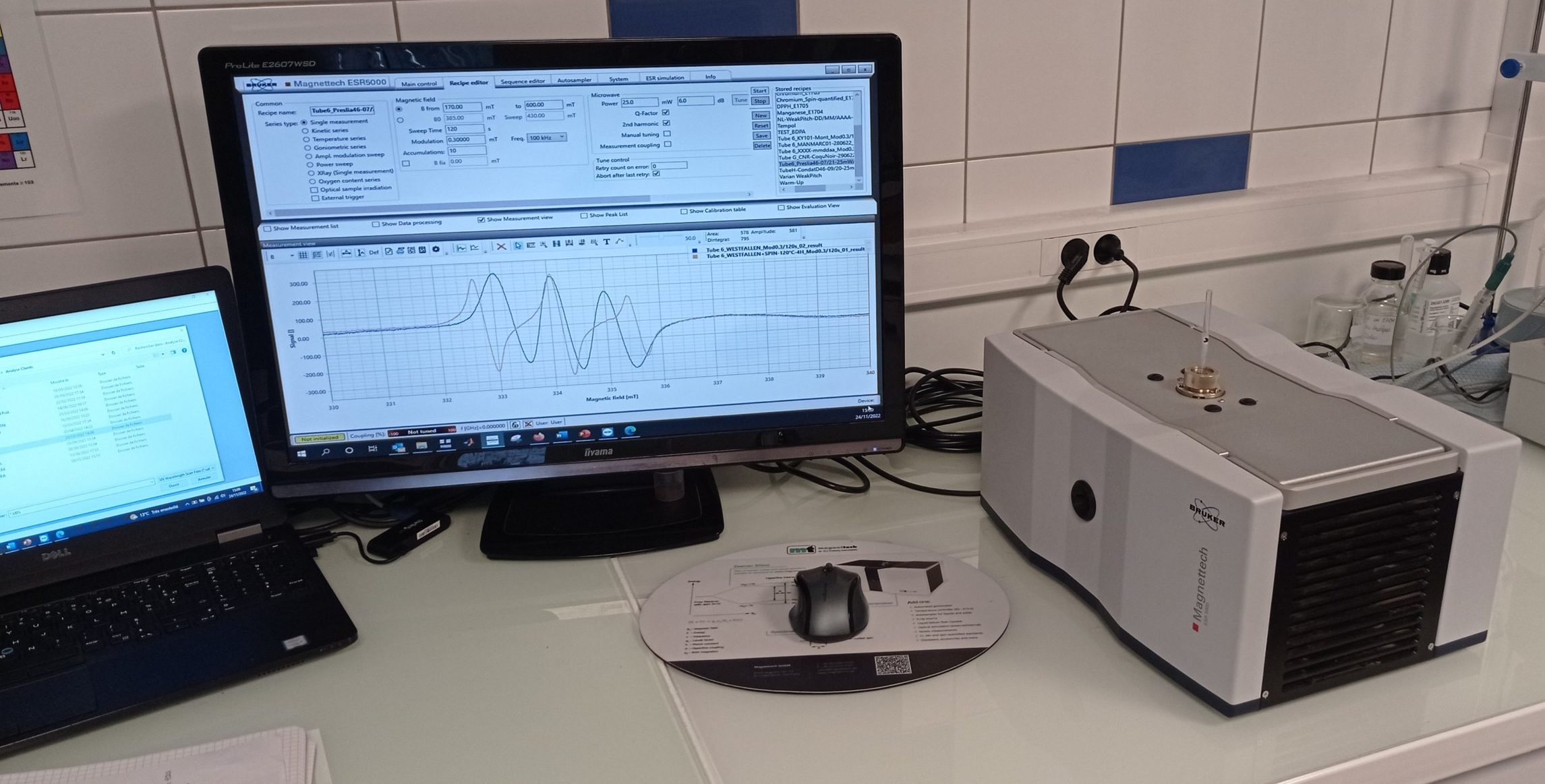

Precision & Reliability

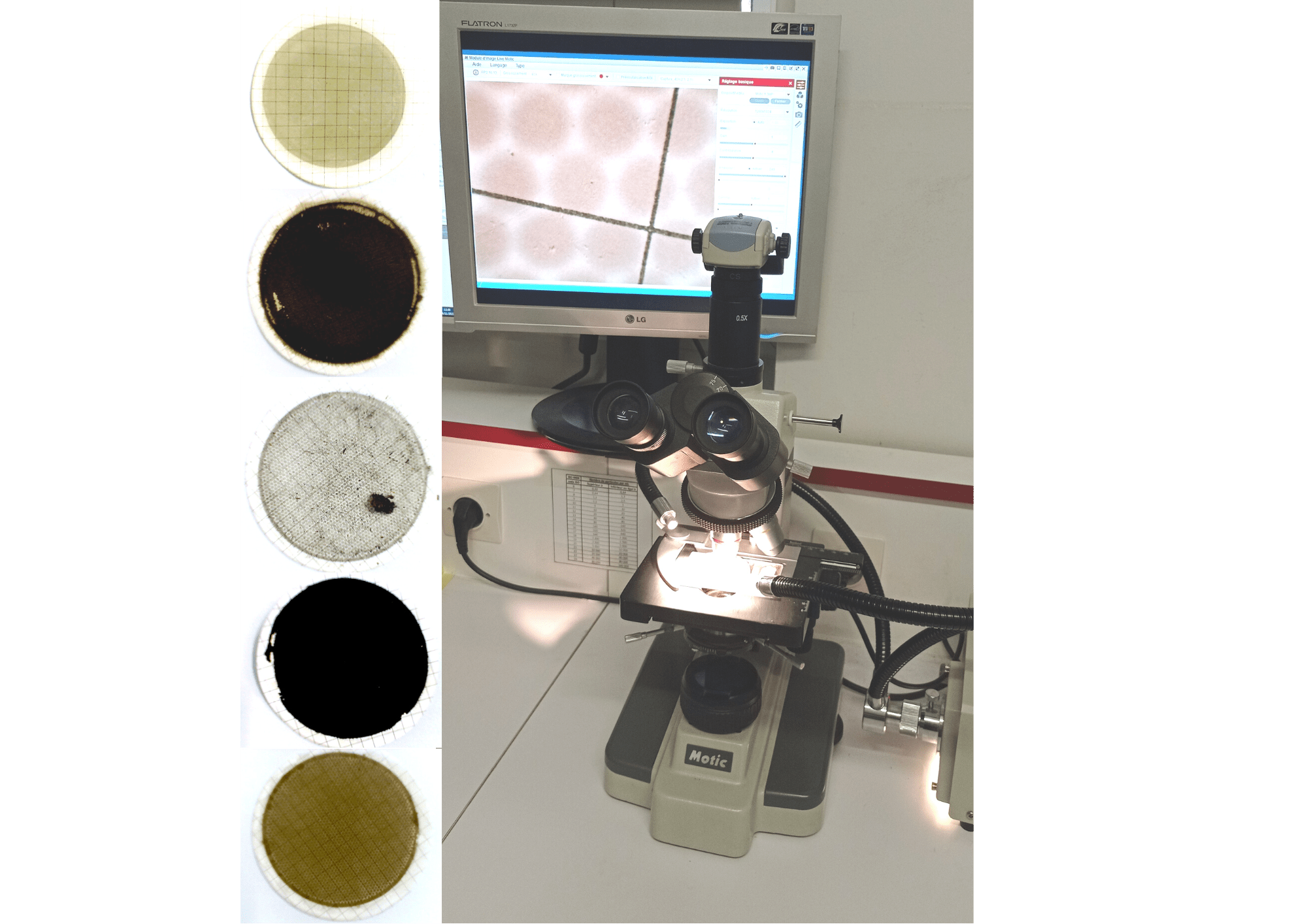

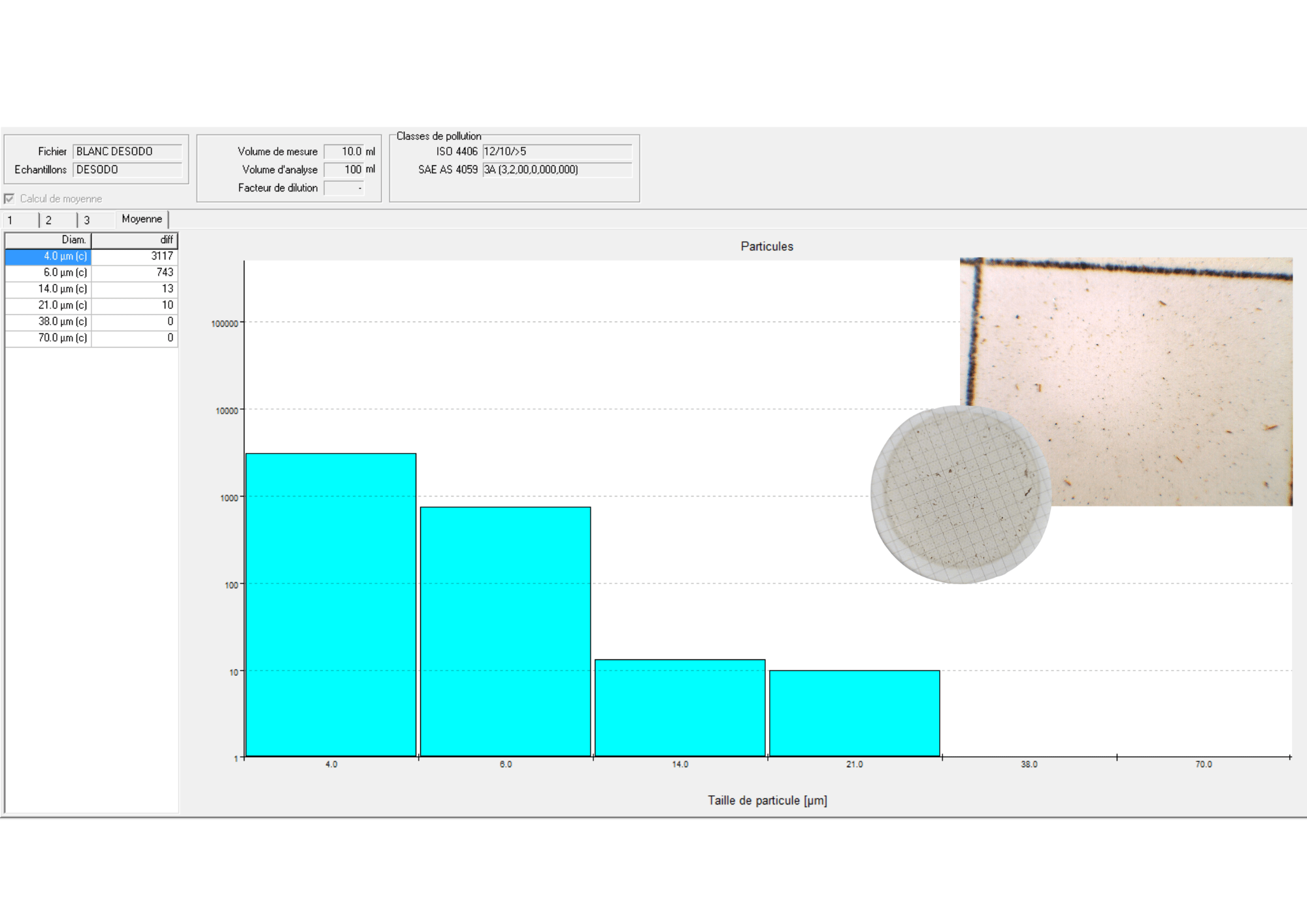

Multi-channel detection with high-resolution laser technology, ISO 11171 compliant.

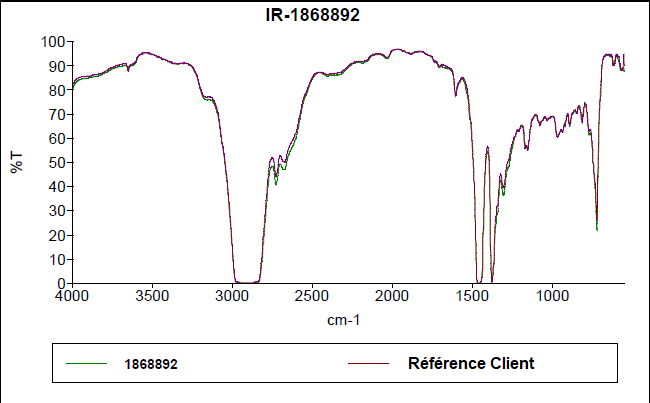

Advantage

Instantaneous analysis of particles with optimized coincidence rate for ultra-reliable measurements.

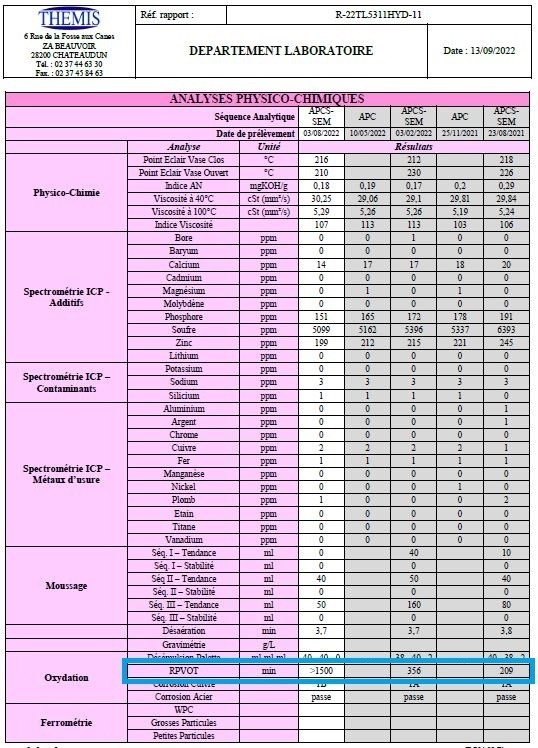

Transmission

Real-time transmission for remote monitoring.