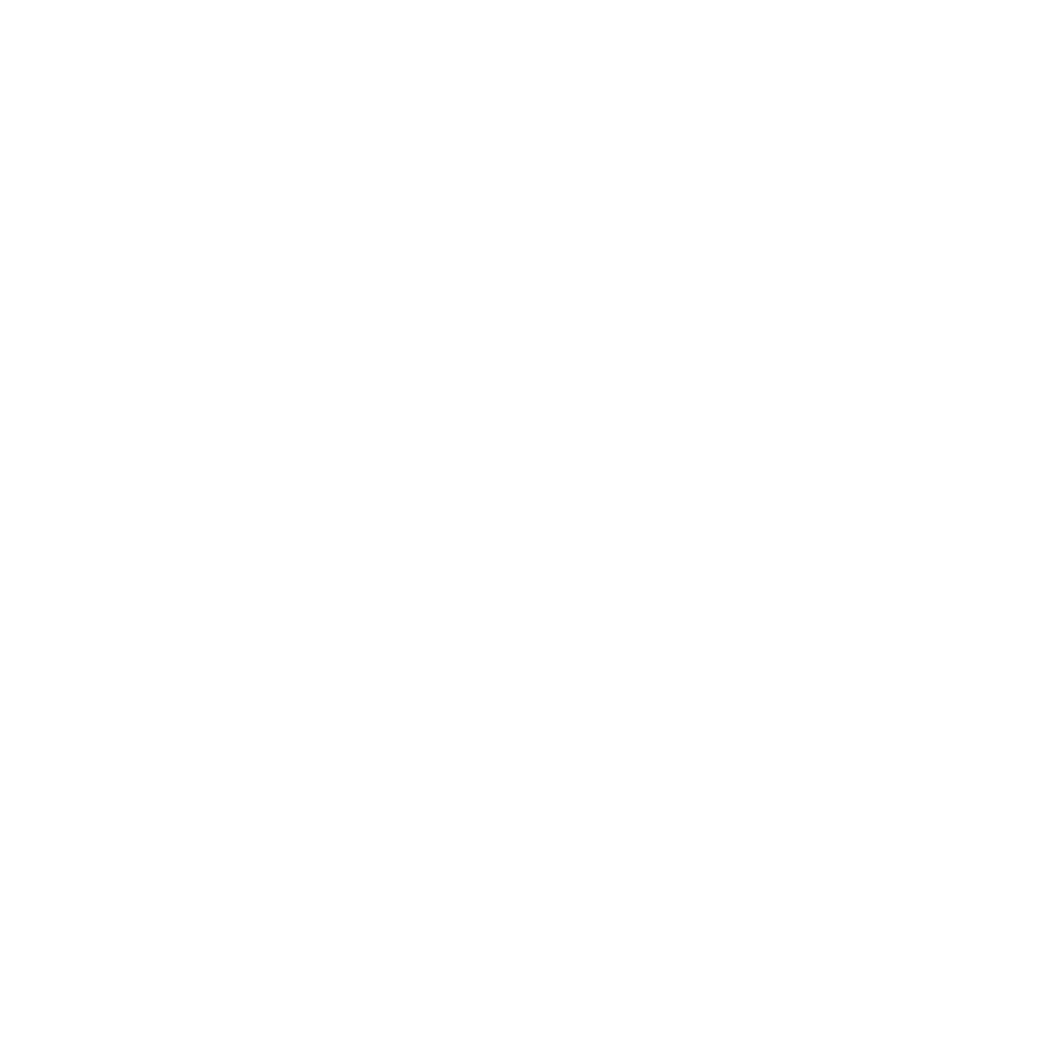

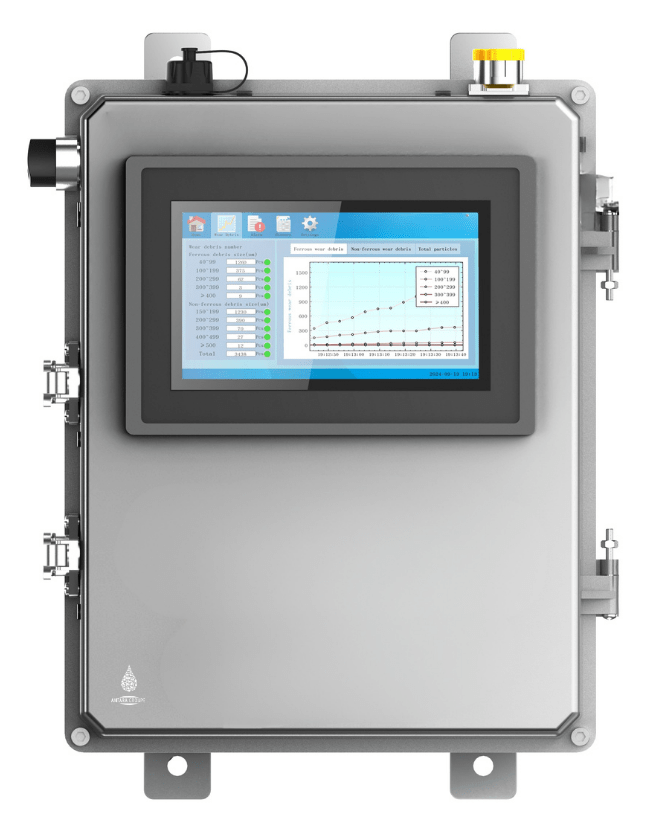

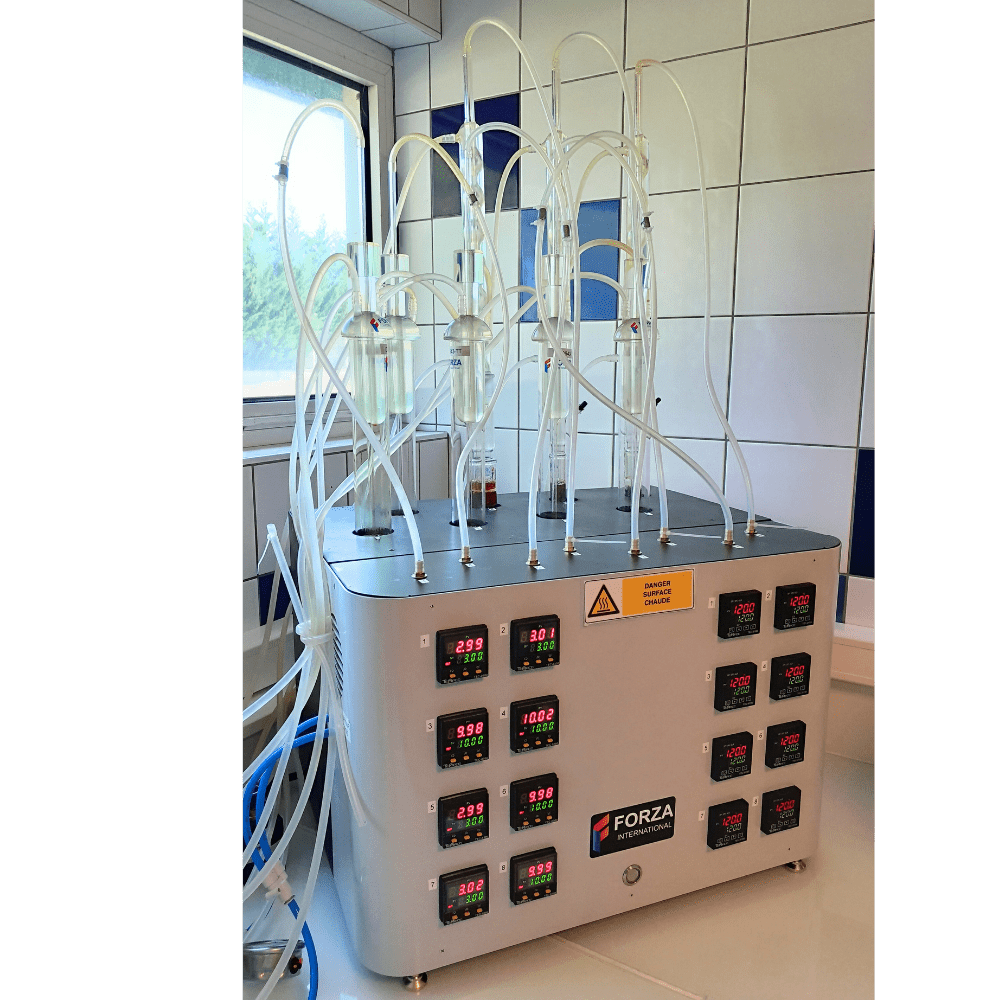

Continuous monitoring without intervention.

Online analysis without filters, sampling, or maintenance.

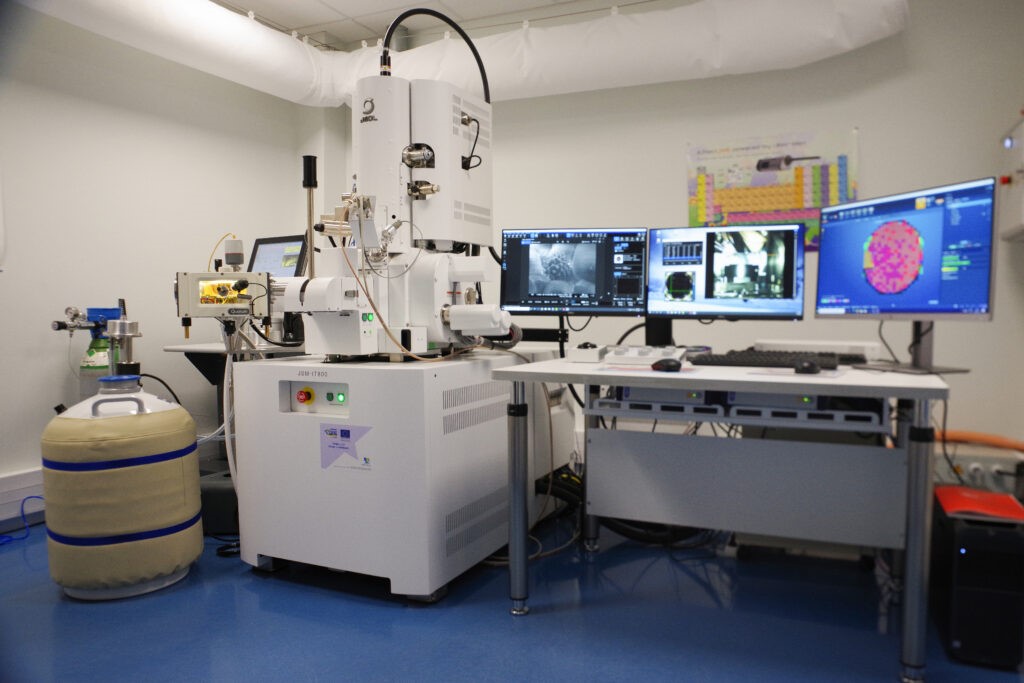

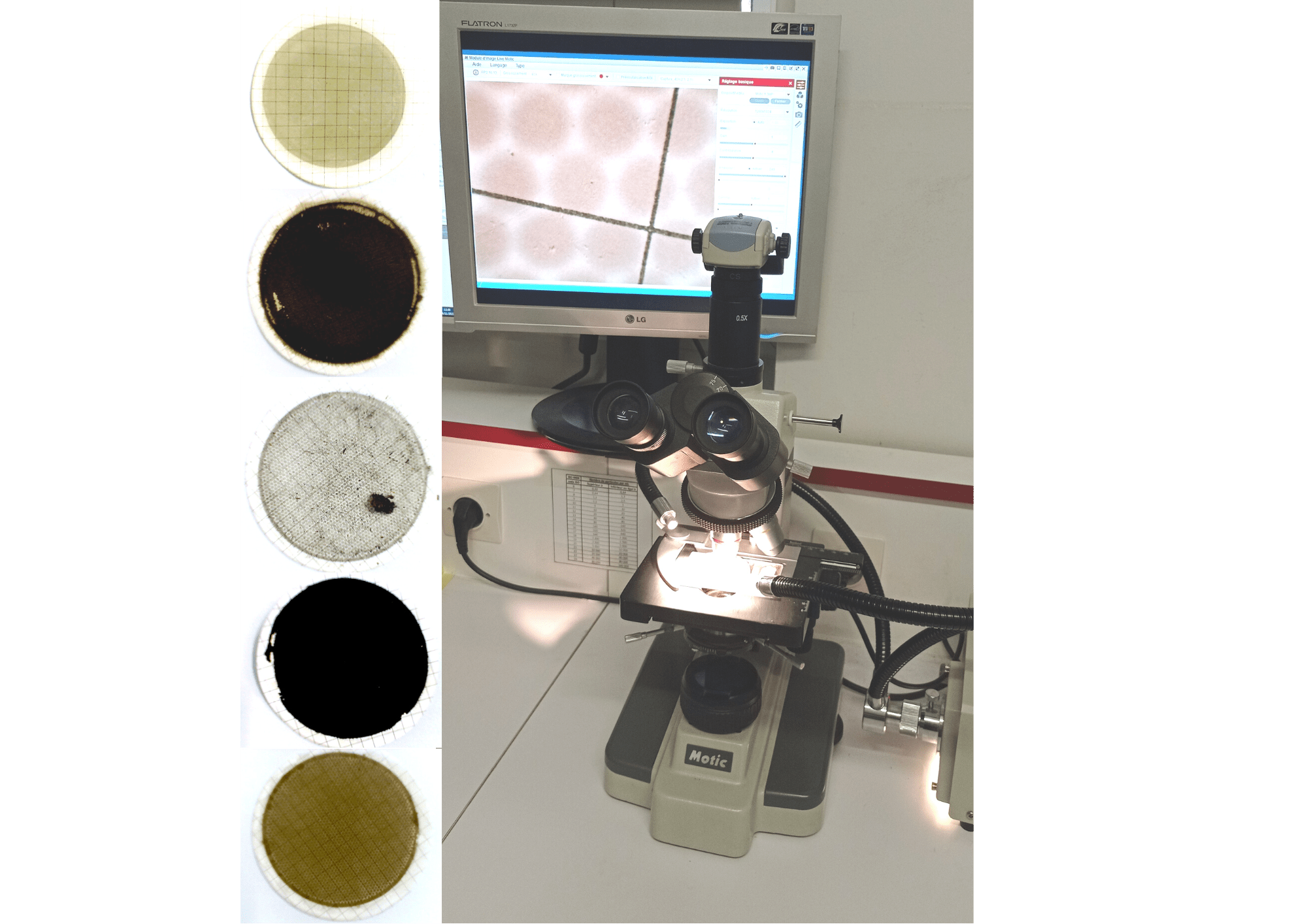

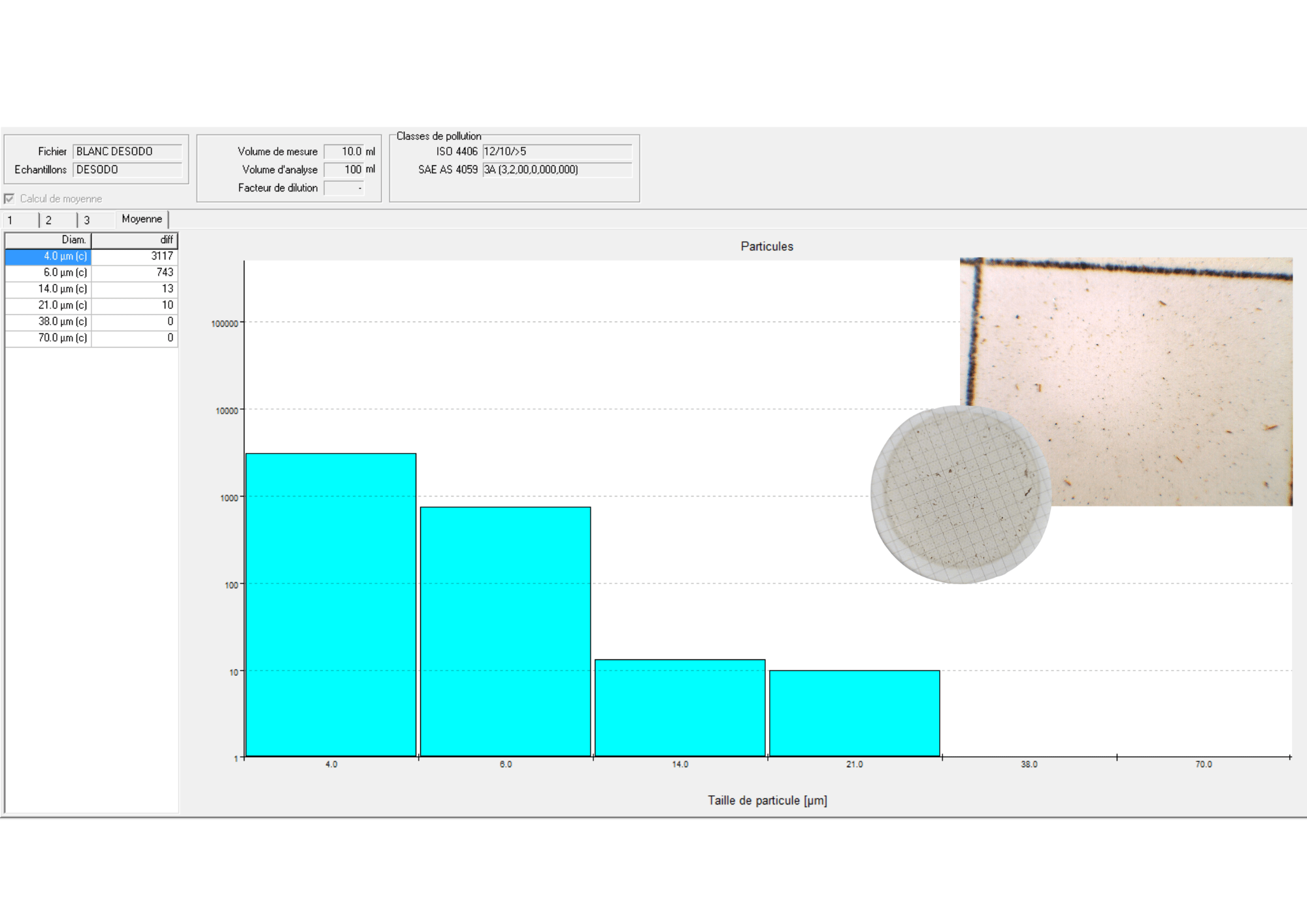

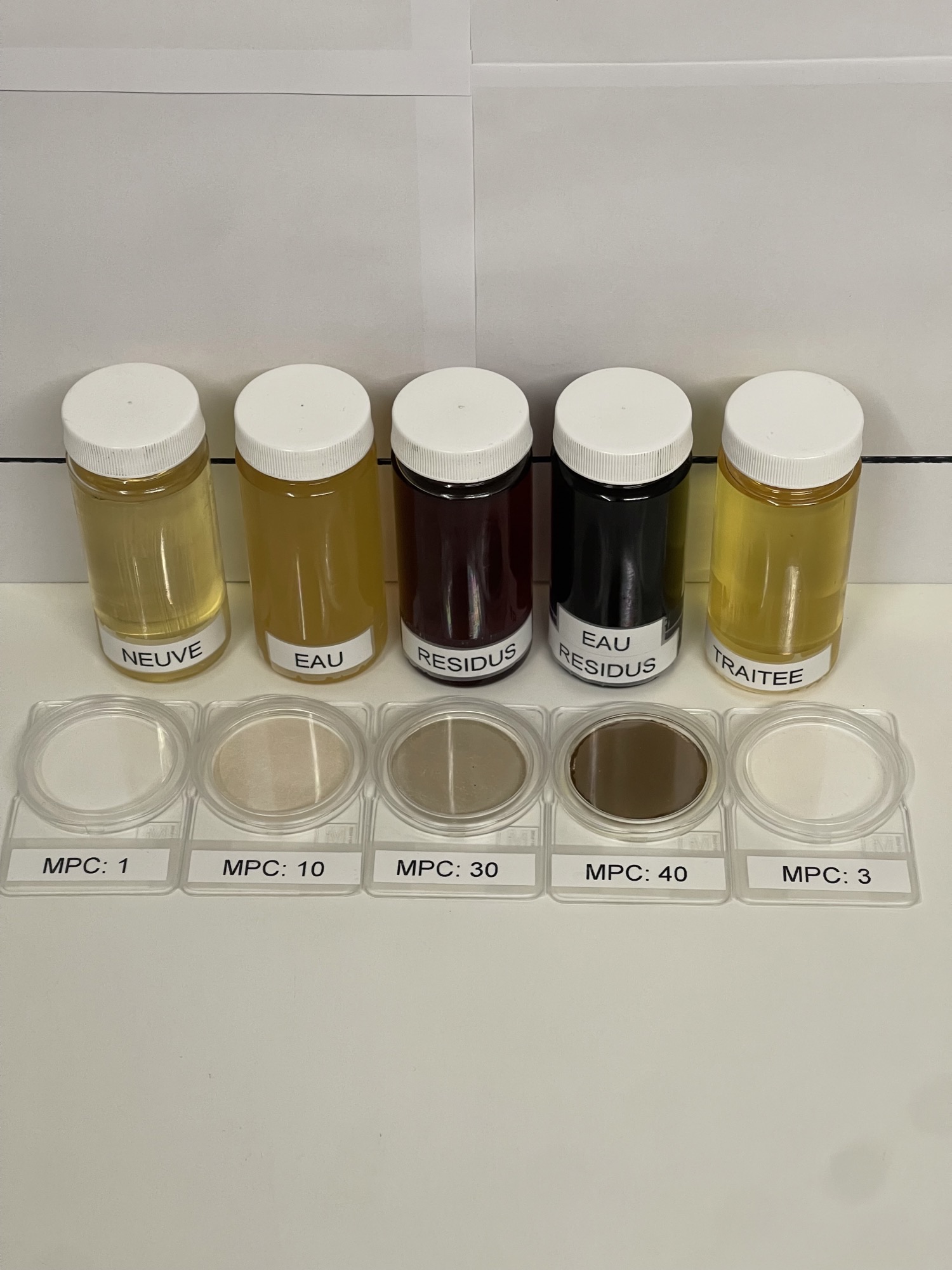

Intelligent particle size analysis

Detection from 40 µm for ferrous particles and 150 µm for non-ferrous particles, with 10 particle size classes.

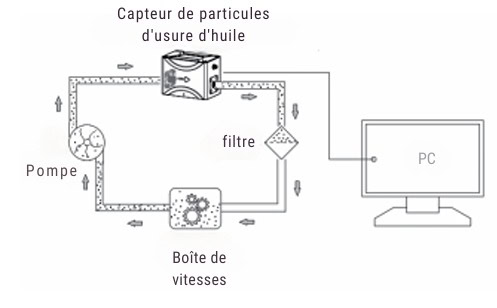

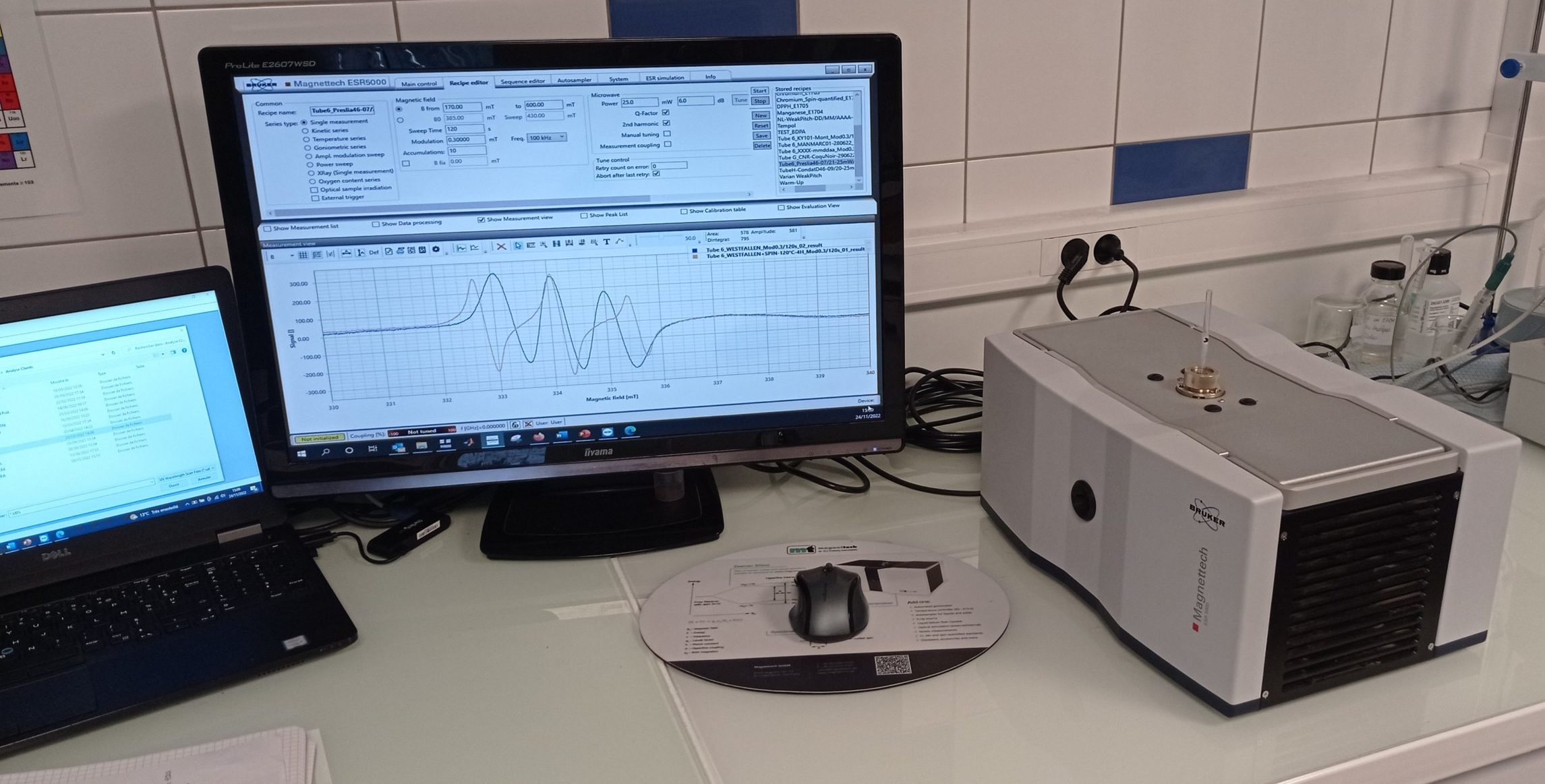

Intelligent dual reading

Identifies separately magnetized and non-magnetized metallic particles for a comprehensive diagnosis.

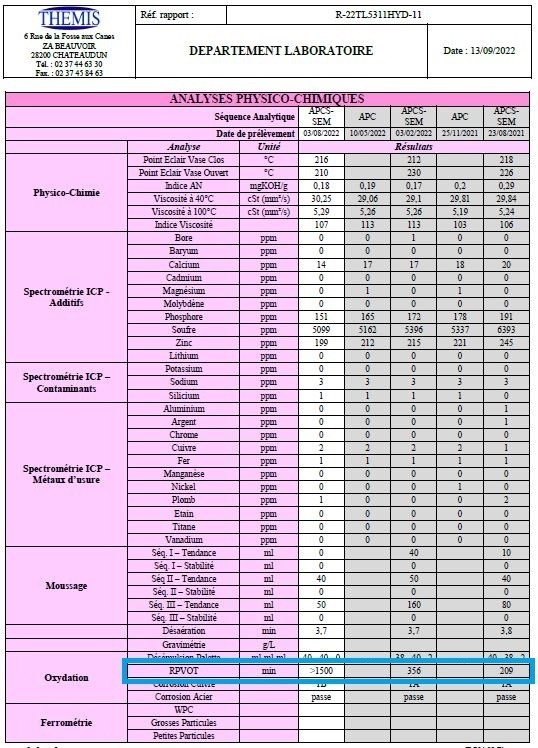

Targeted detection of critical wear

Enables identification of the type of mechanical degradation based on the nature and size of the particles.