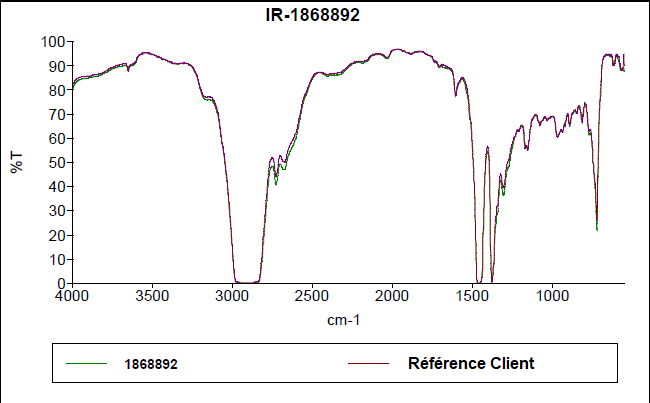

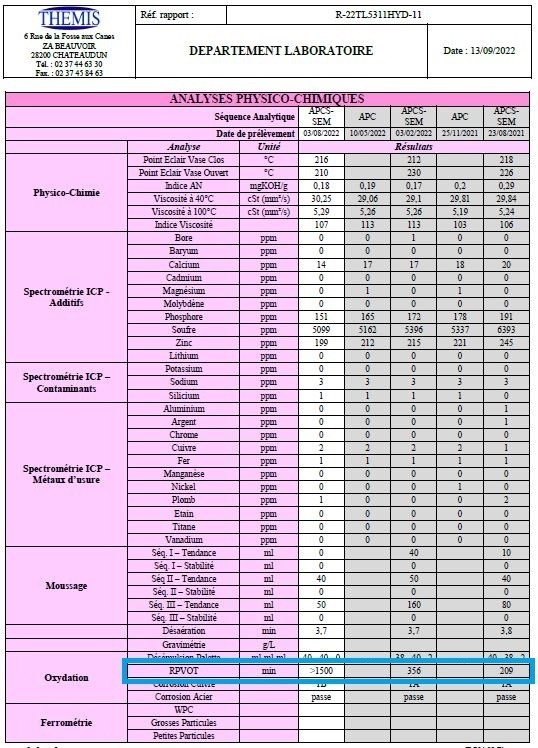

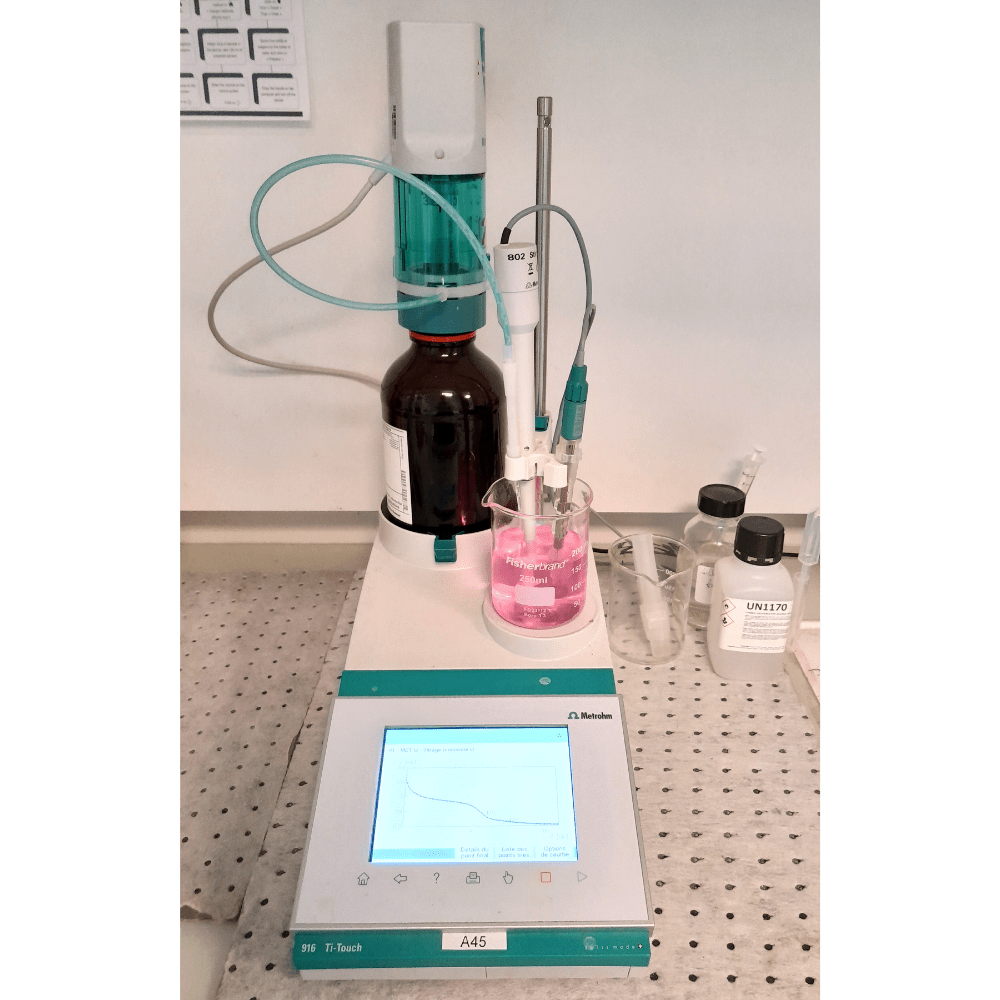

Diagnosis and correlation

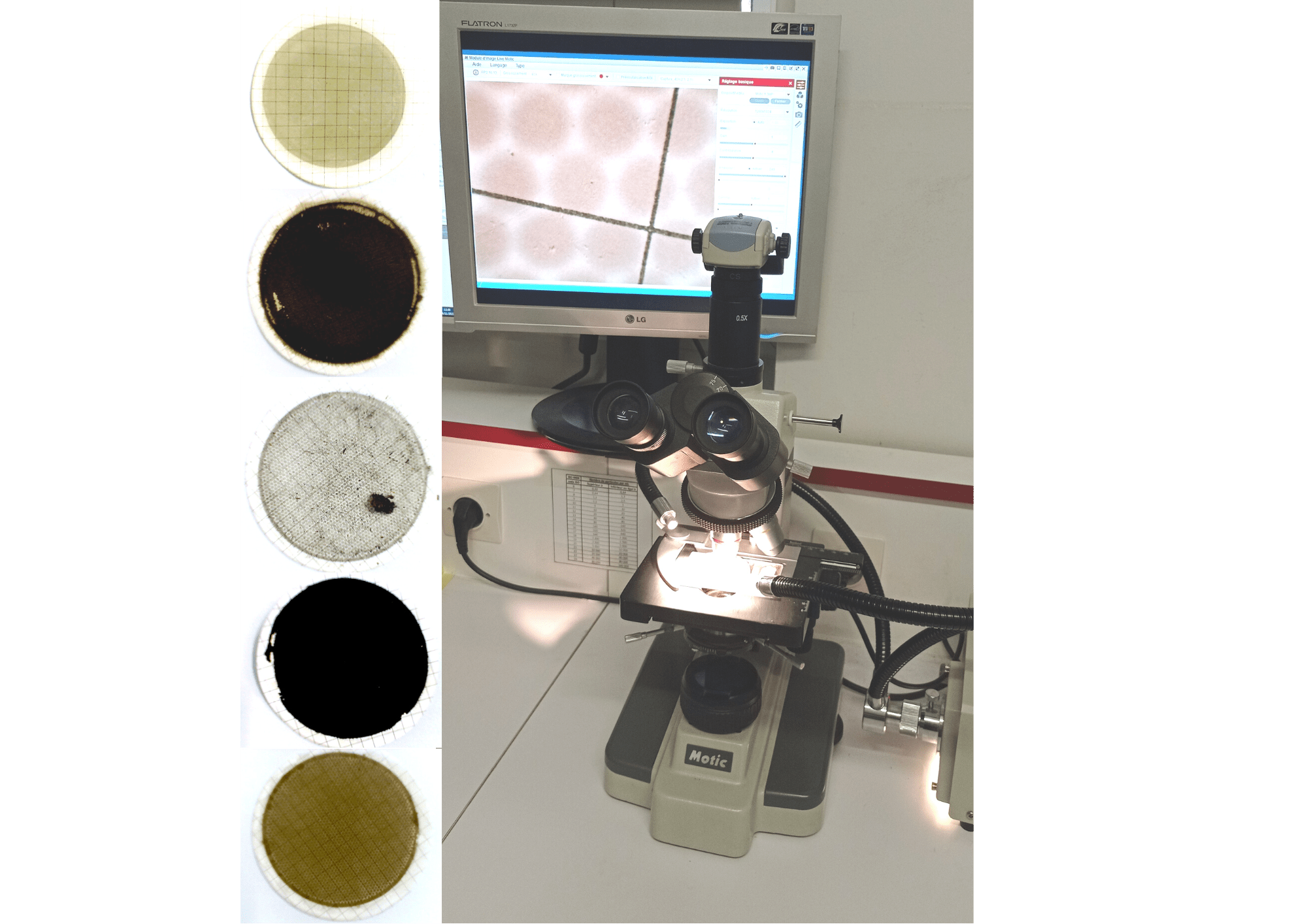

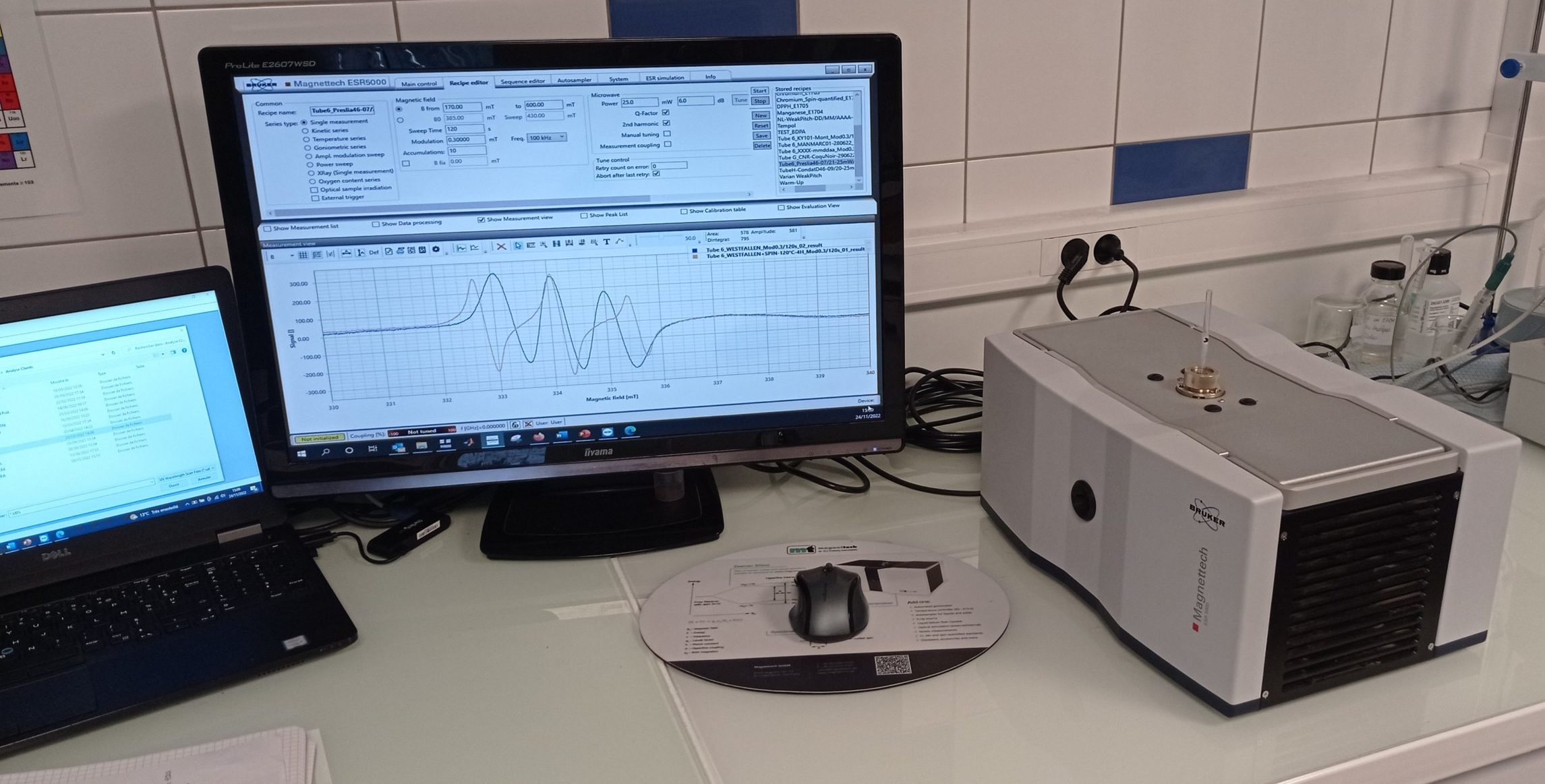

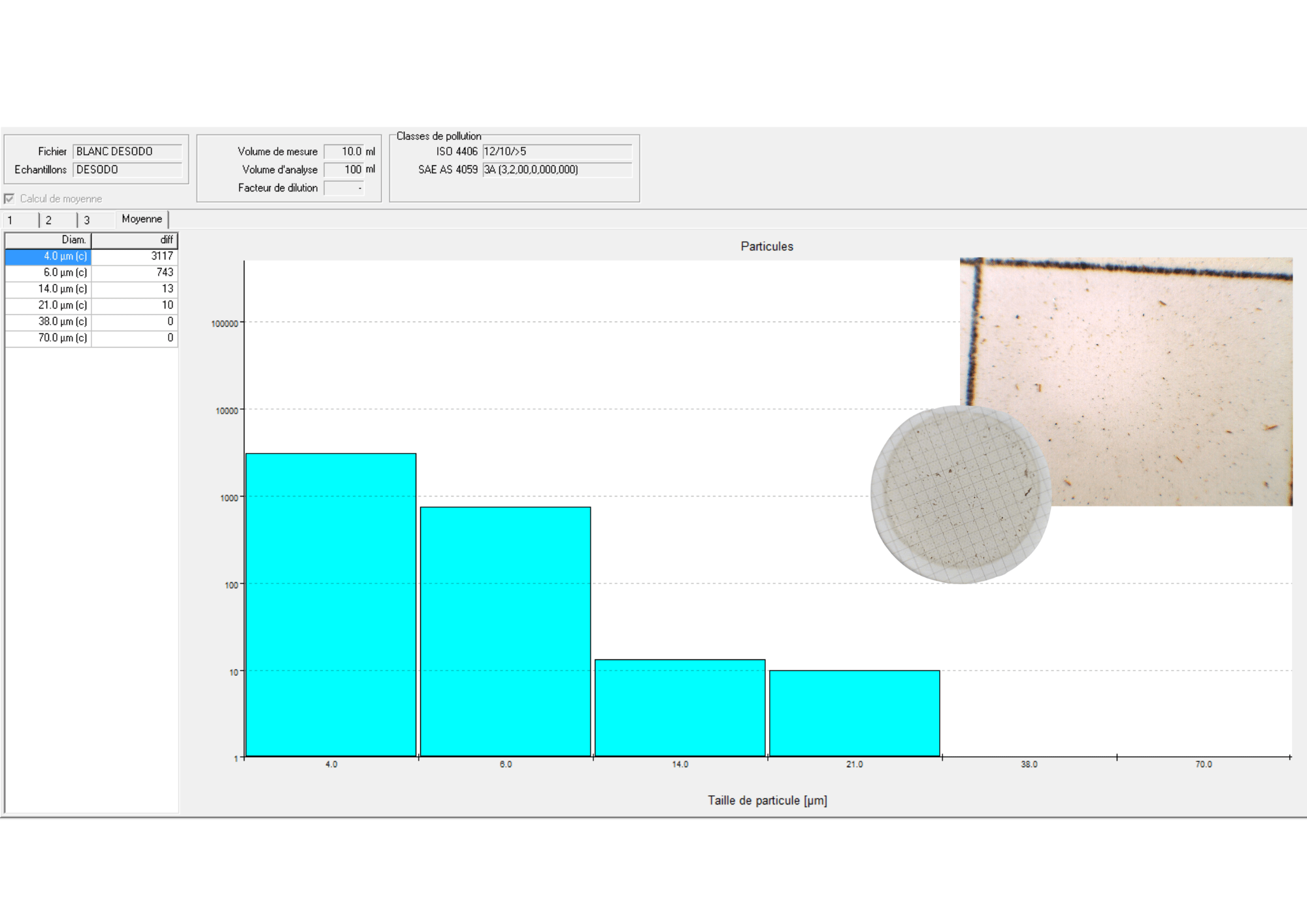

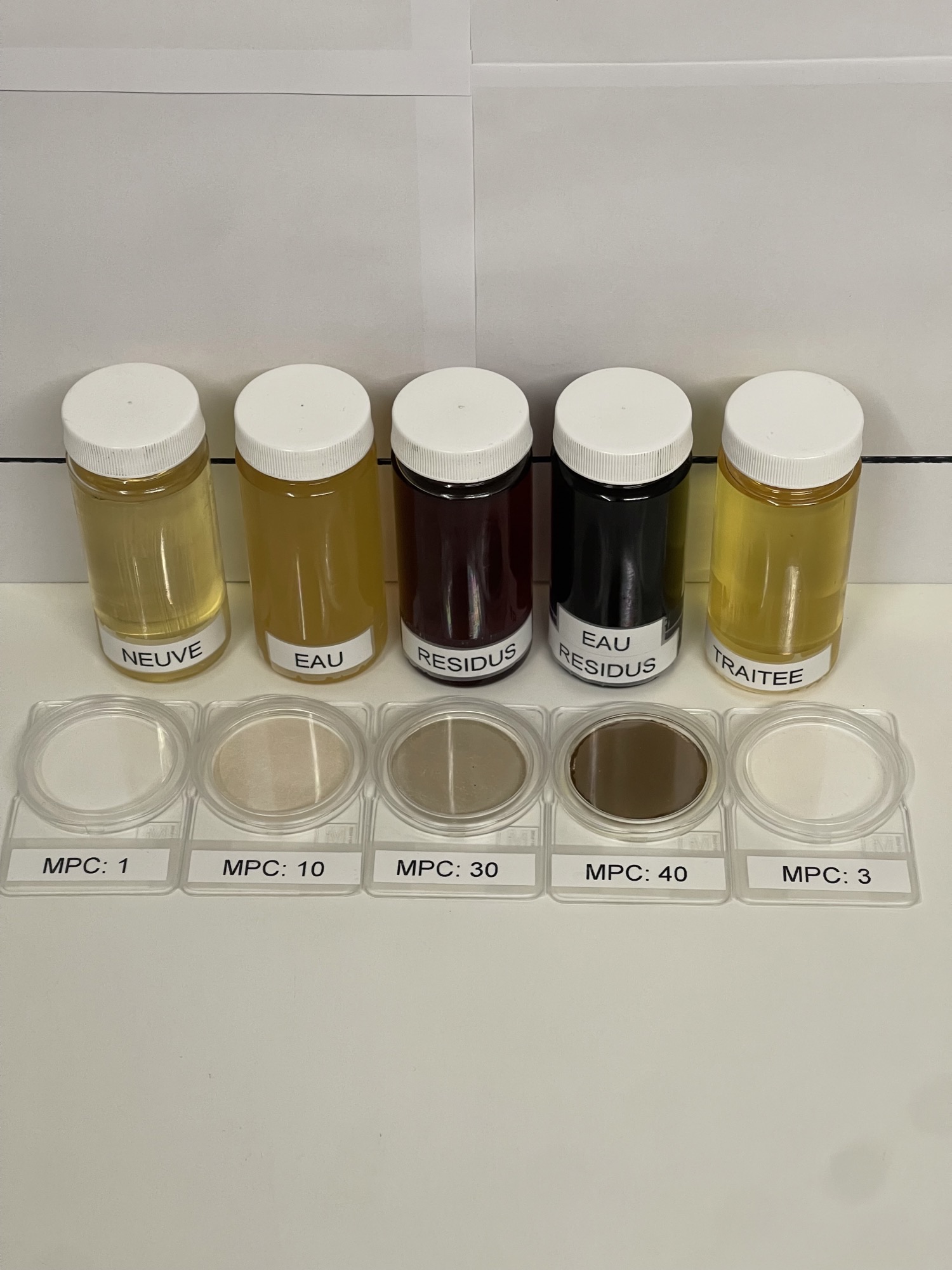

Joint analysis of signals and all data, for example associated with viscosity, density, water, particles, etc., to qualify the condition of the fluid and detect deviations.

Prevention and prioritization

Alerts prioritized by risk level, trend, and rate of change to intervene at the right time.

Proprietary models & embedded intelligence

Models designed and calibrated in-house, enriched by historical data, AI data, and field feedback (REX) to increase the relevance of alerts and diagnostics.

Remote control and traceability

Access your data wherever you are via Cloud and 4G/WiFi connection.