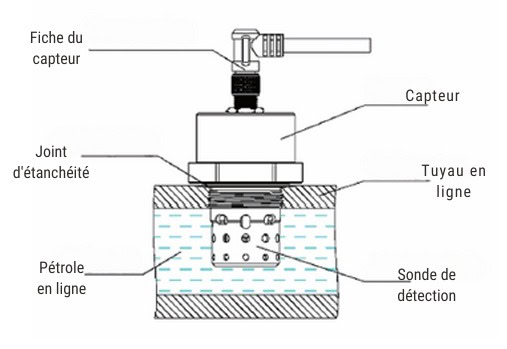

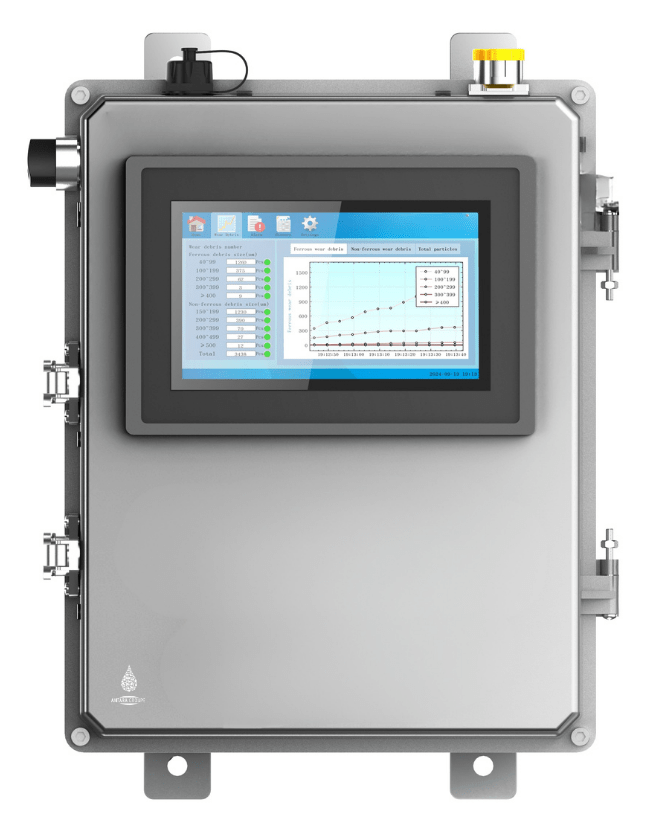

Complete real-time measurement

A single sensor to monitor 6 critical parameters of the oil, continuously and without sampling.

Designed for industry

Robust housing in 316L stainless steel, IP66 rated, resistant to harsh environments.

Immediate operational gain

Instant data, directly usable in your systems (PLC, supervision, predictive maintenance).

Simplified integration

Connection via RS485 or CAN, standard M39 thread, 24 VDC power supply – ready to install.