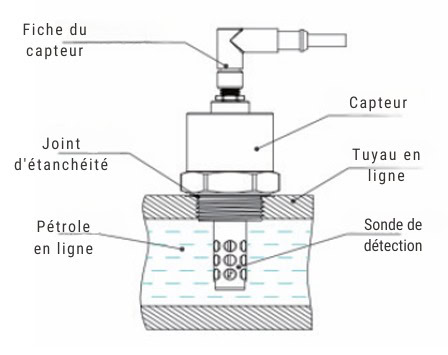

Targeted monitoring

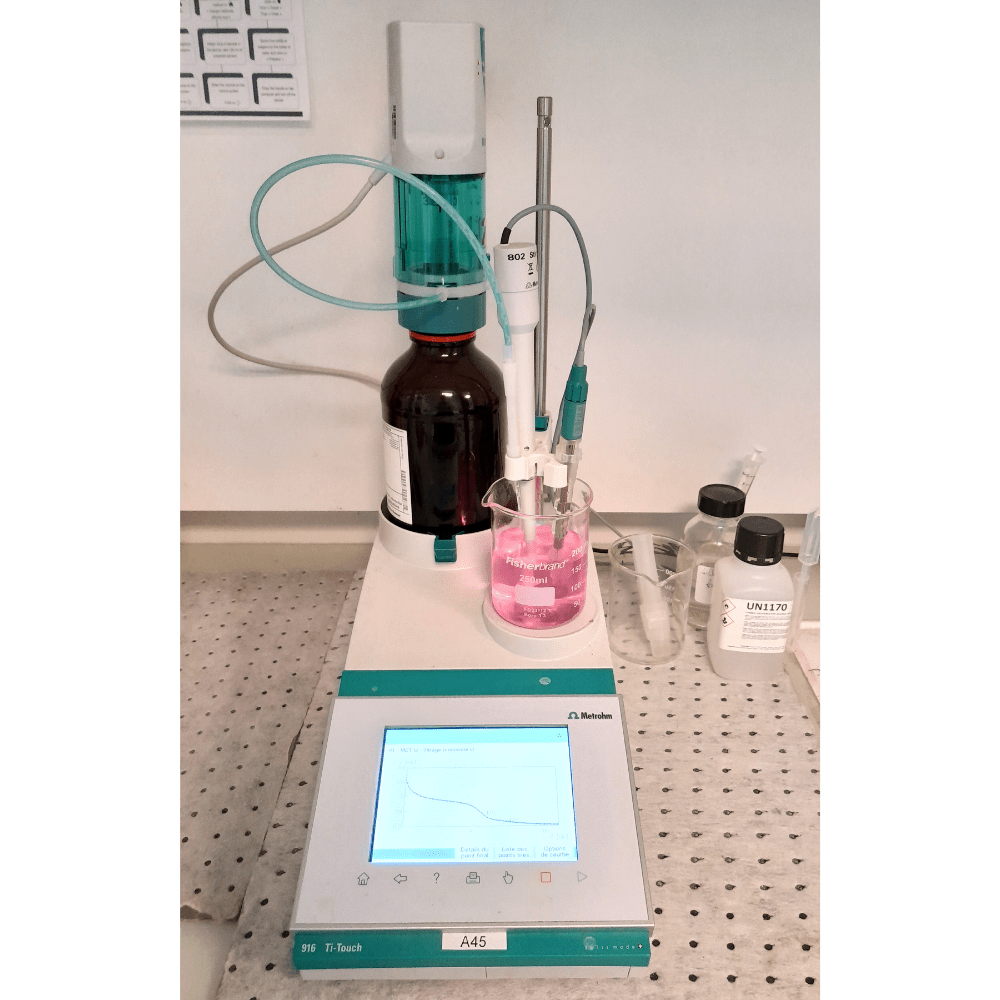

Specifically designed to measure humidity in mineral, hydraulic, synthetic oils, etc.

Industrial robustness

316L stainless steel housing, IP66 protection, designed to last in harsh environments.

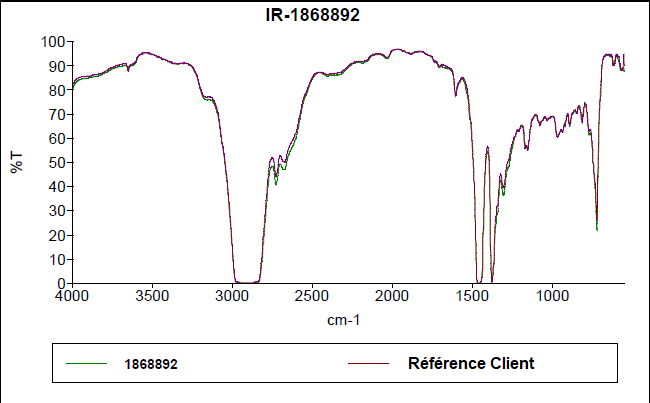

High precision dedicated Water

Combined measurement of relative humidity (aW) and dissolved water (PPM ) with high reliability.

Simple connectivity

RS485, 4–20 mA or CAN 2.0B outputs, compatible with all your monitoring systems.