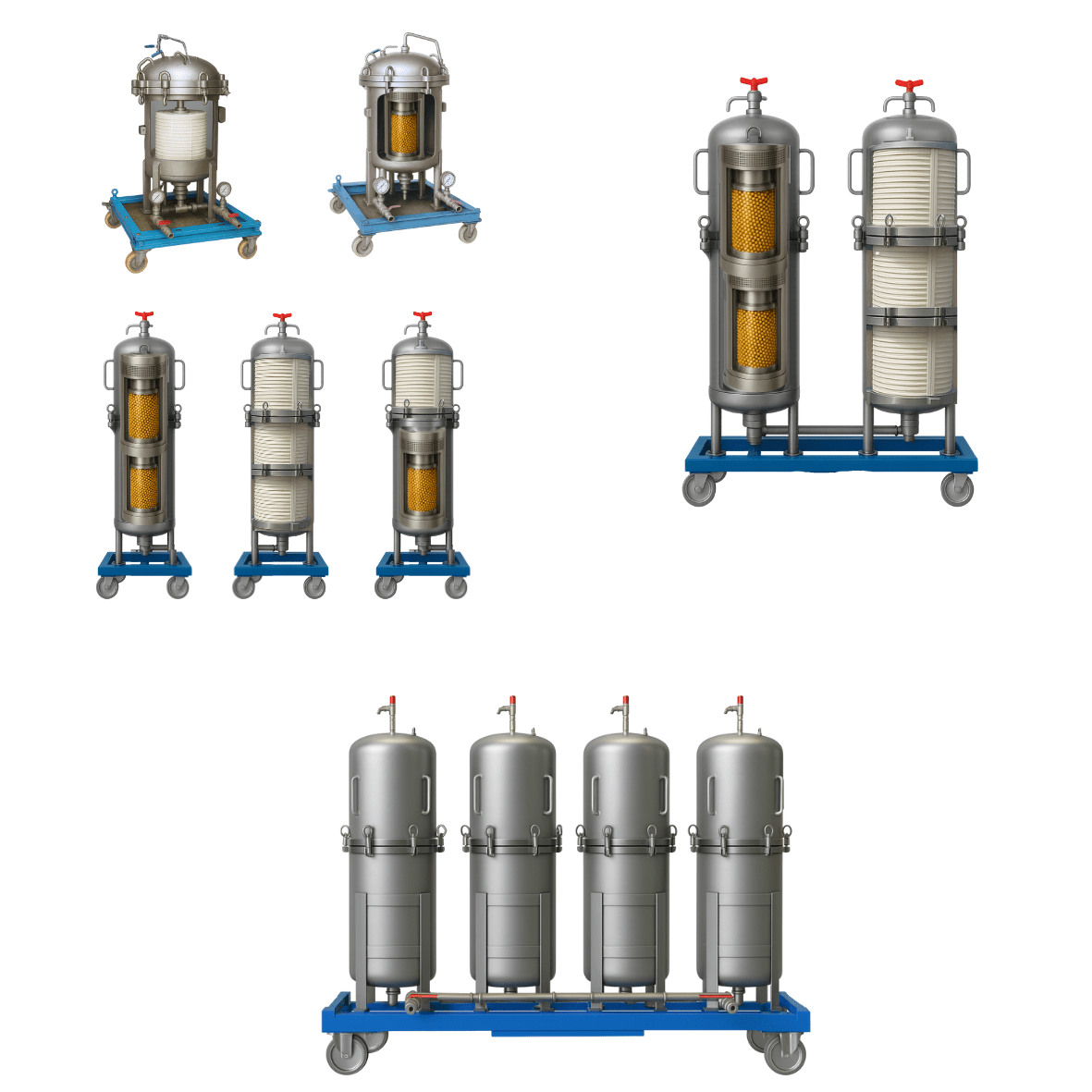

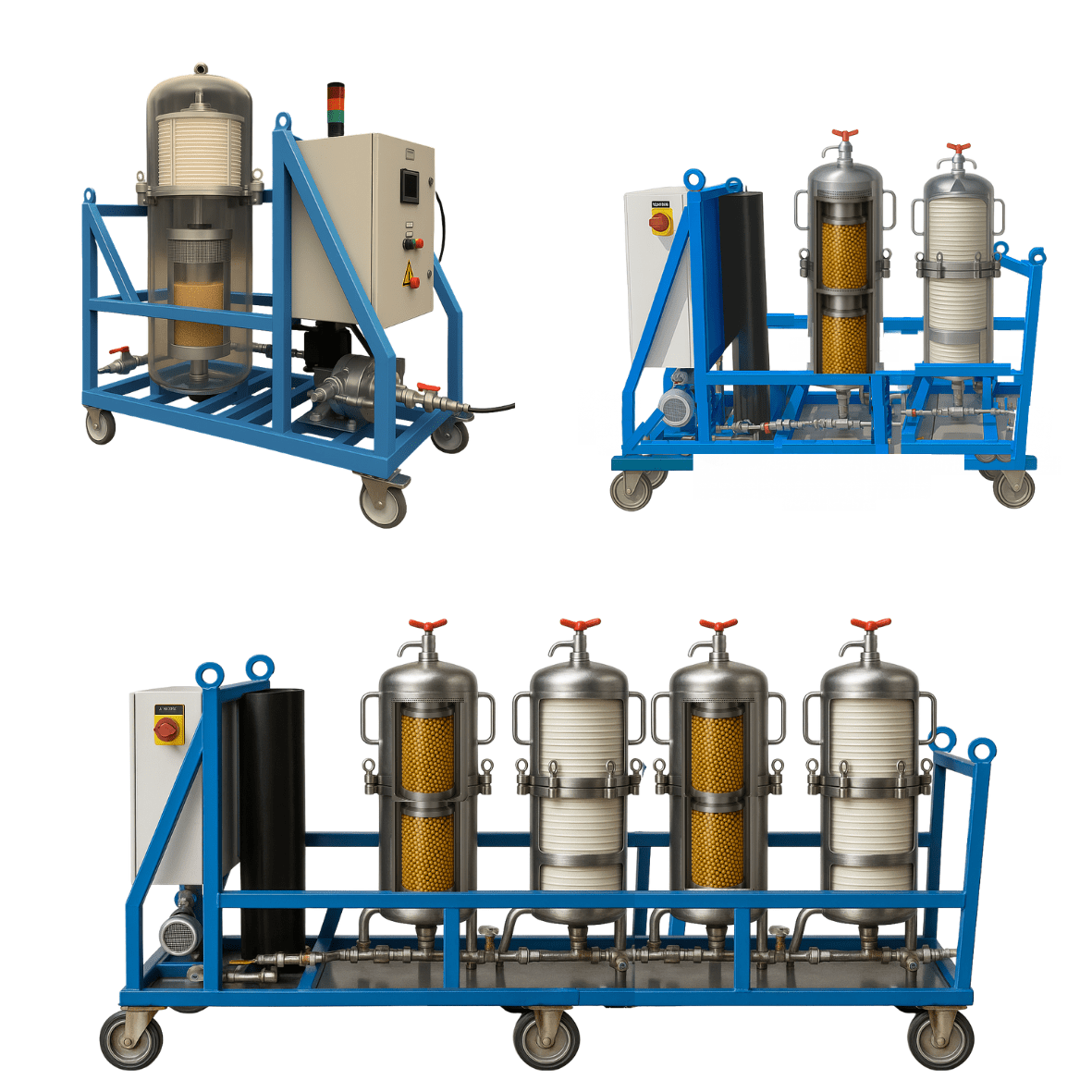

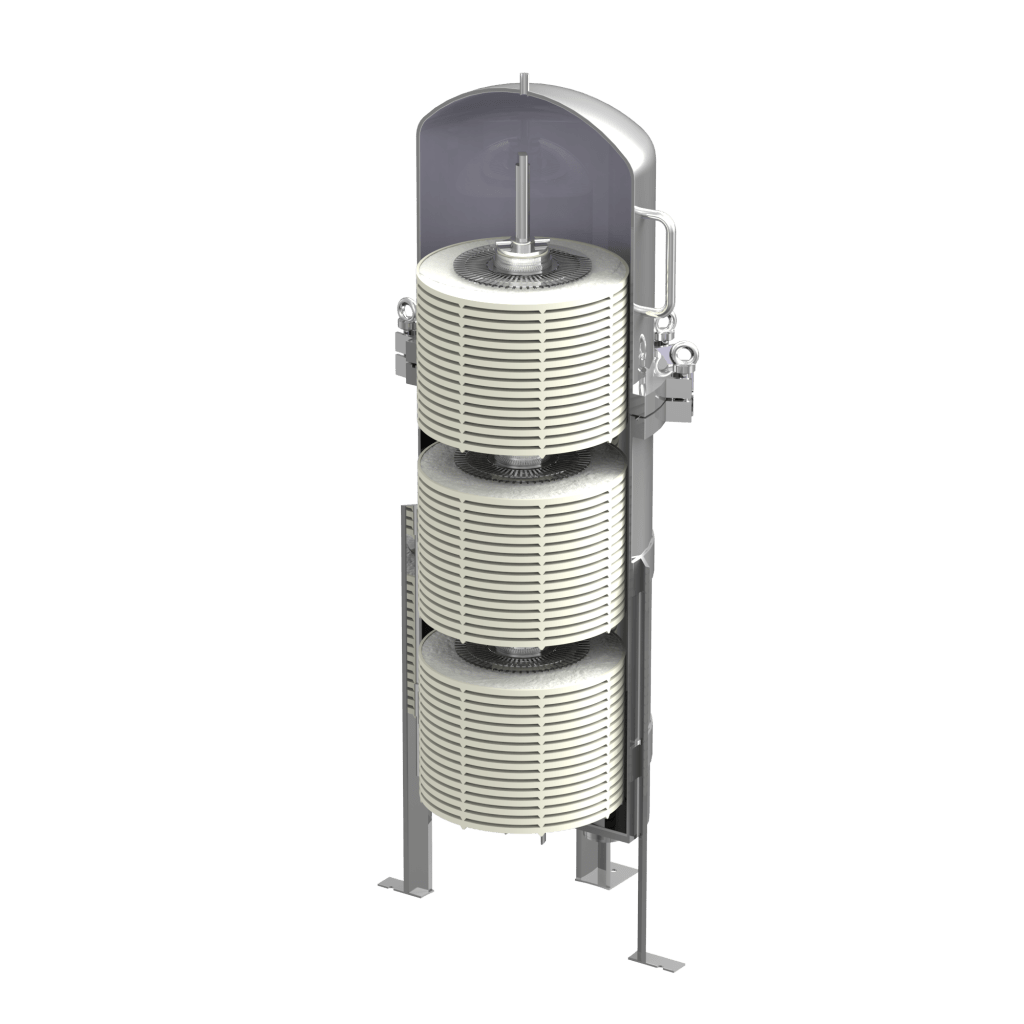

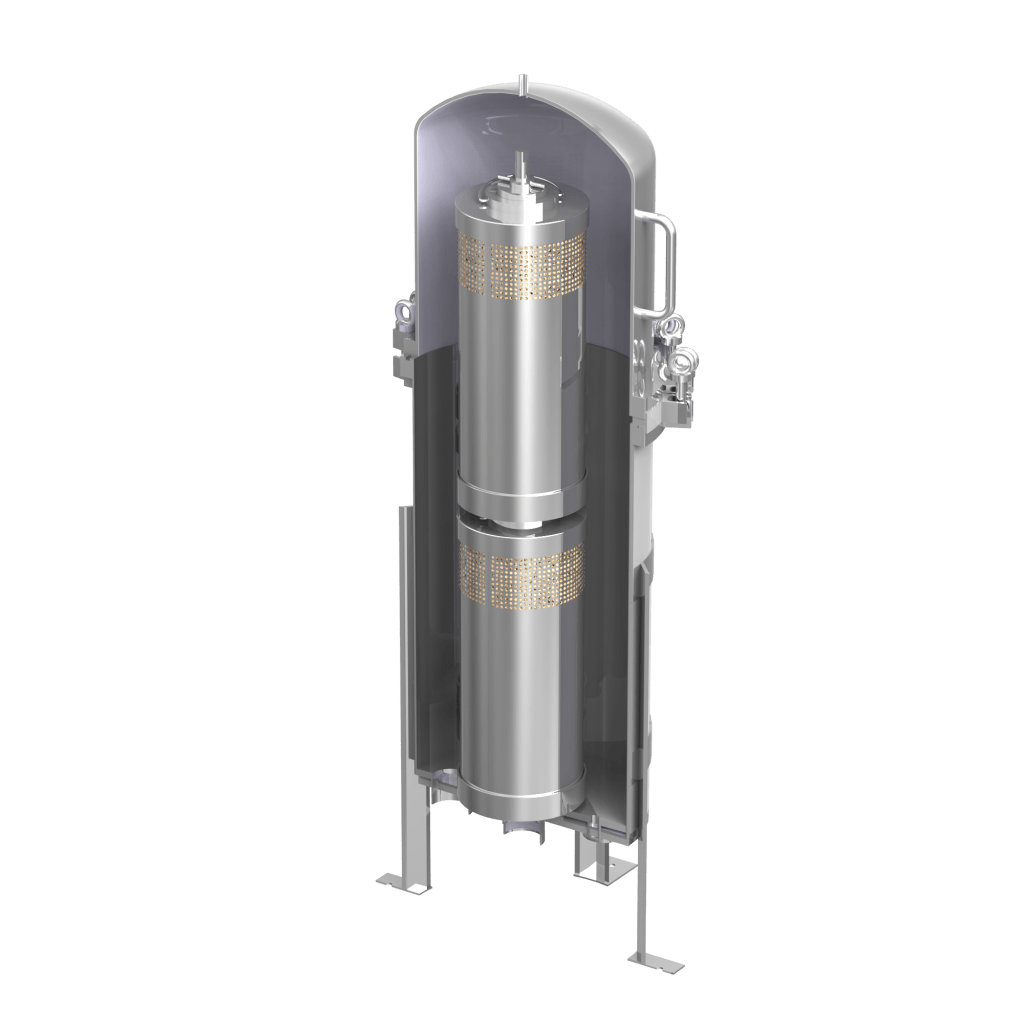

TRO DUAL SYSTEM

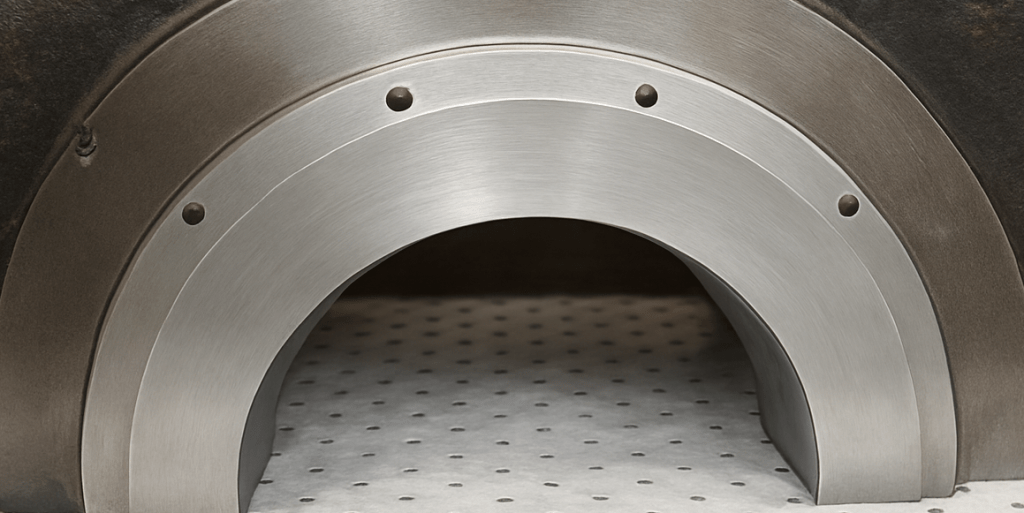

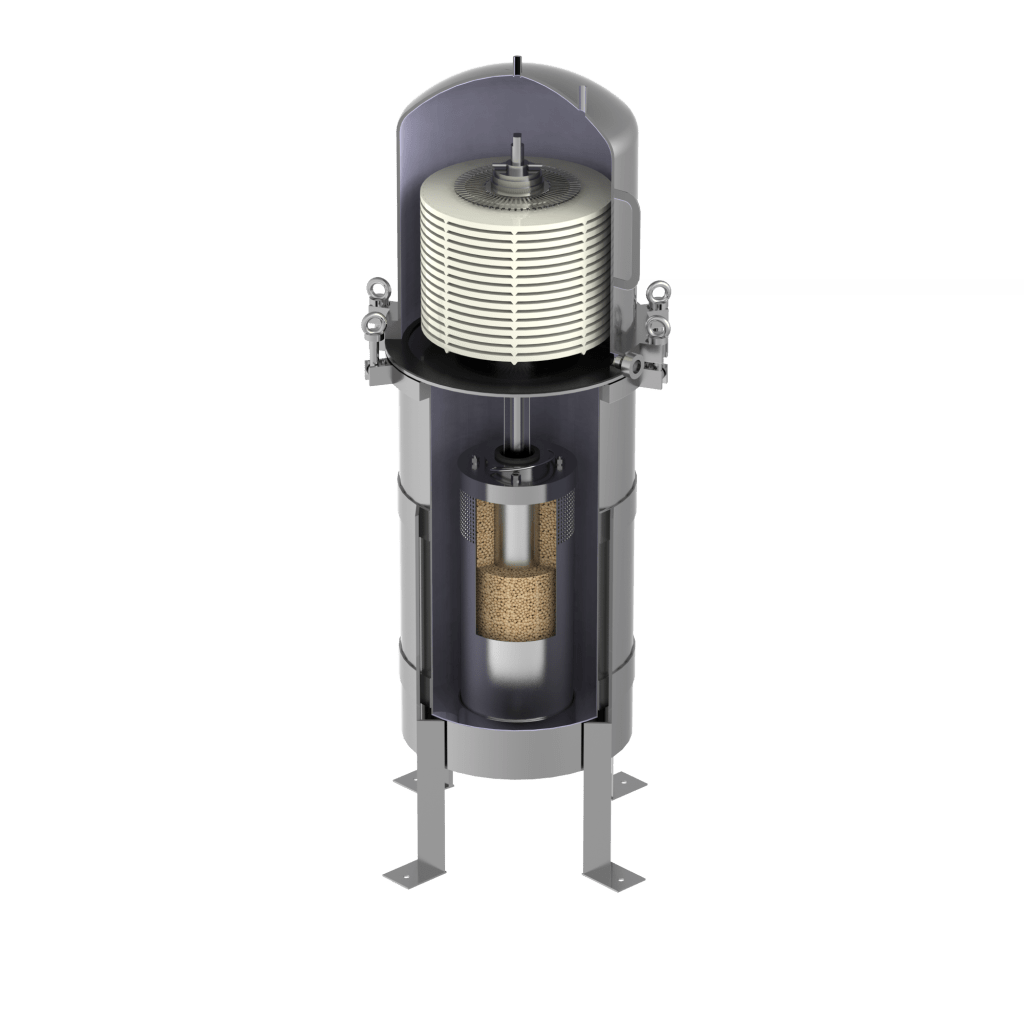

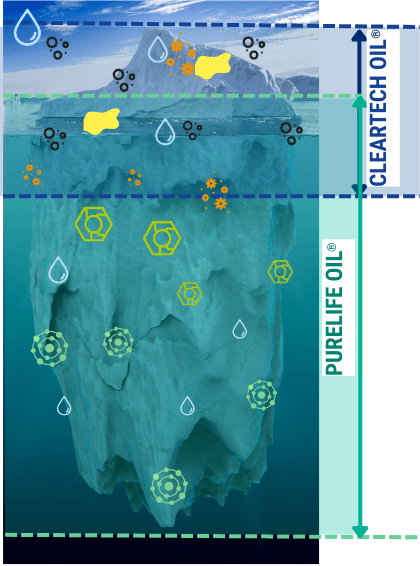

A flexible filtration SKID that uses Cleartech and Purelife technology and adapts in real time to your needs to protect your oils, additives and sensitive equipment.

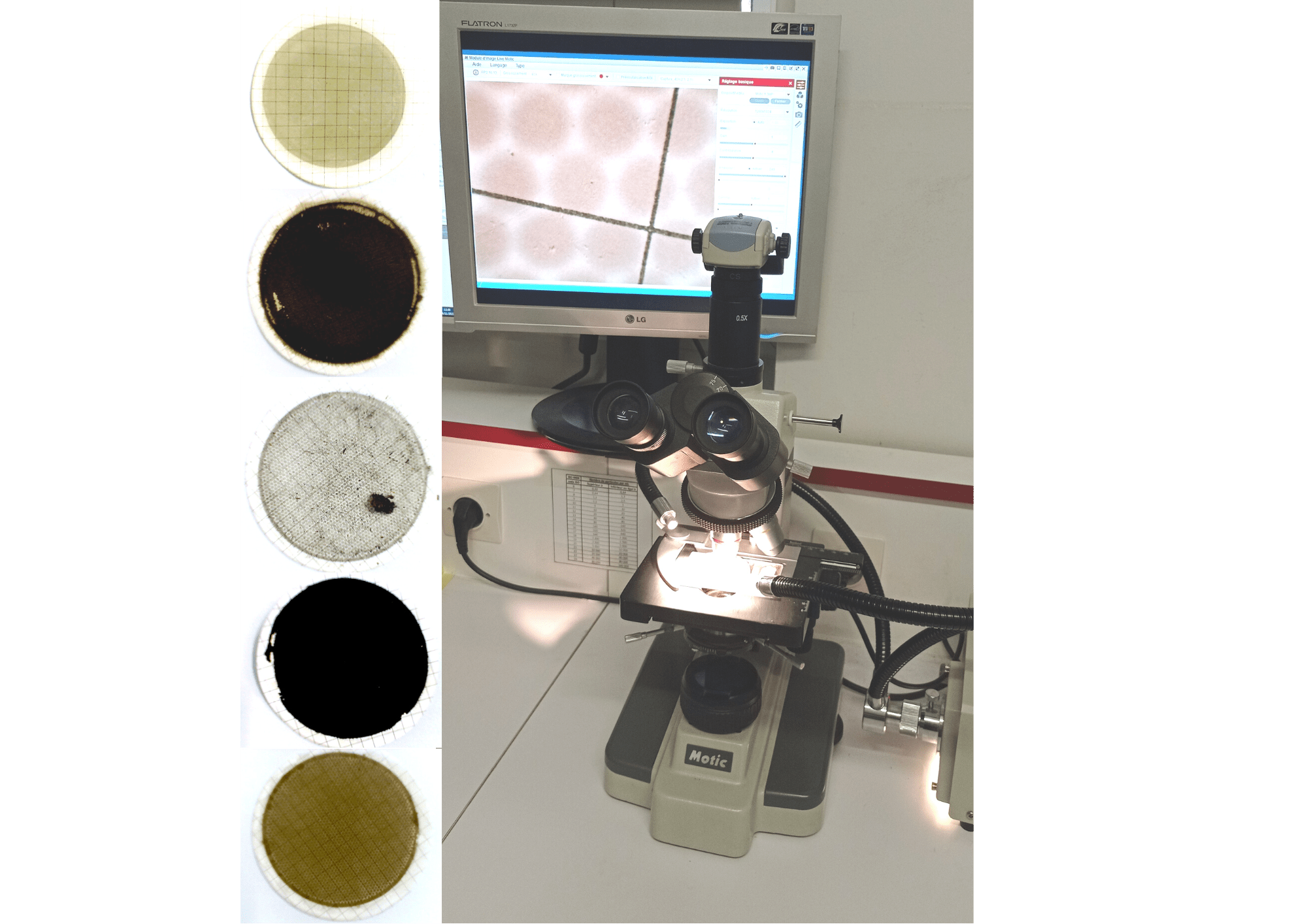

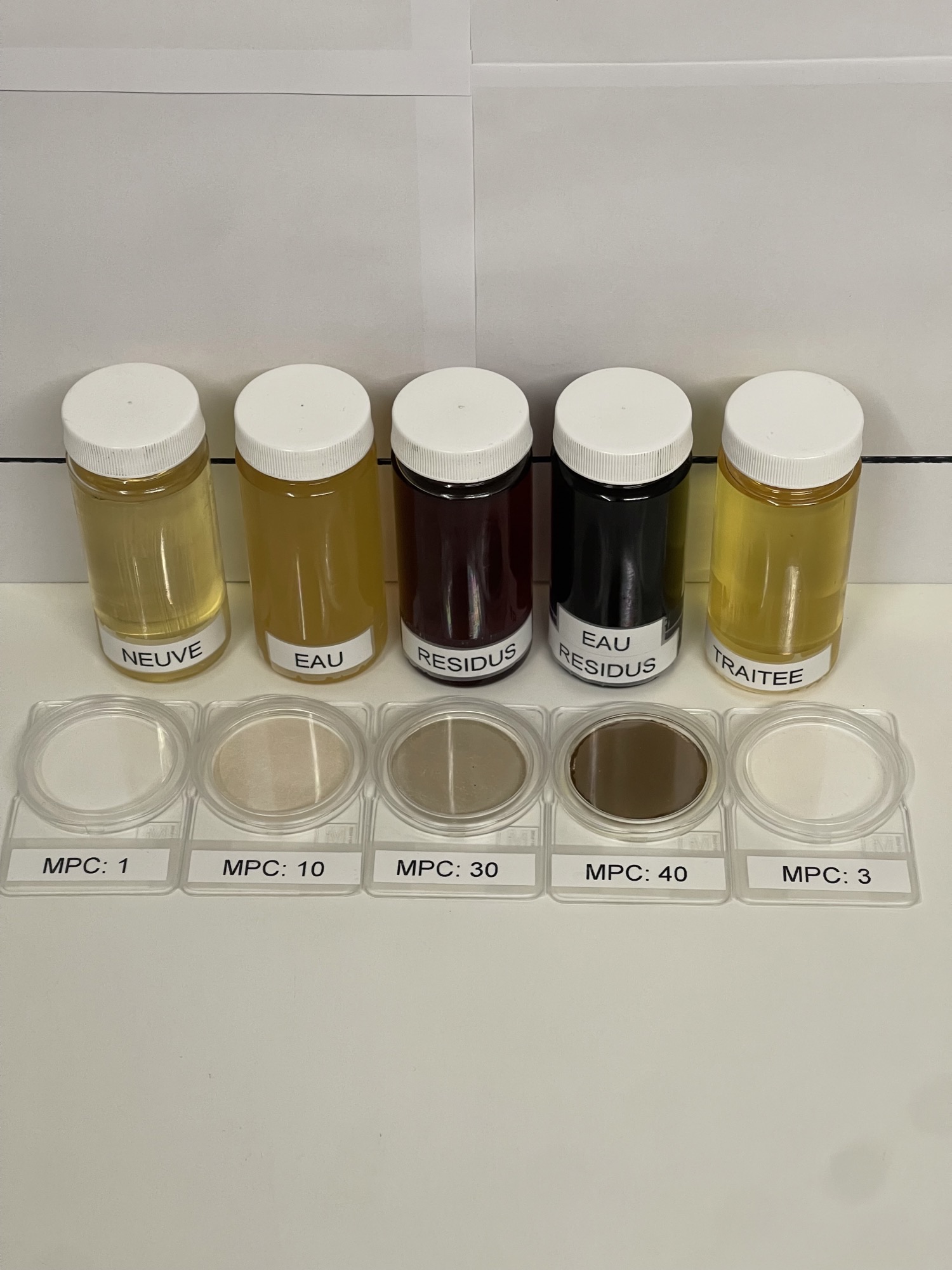

Treated fluids

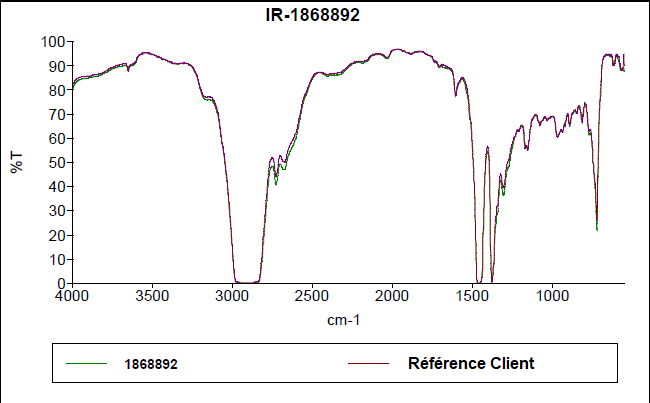

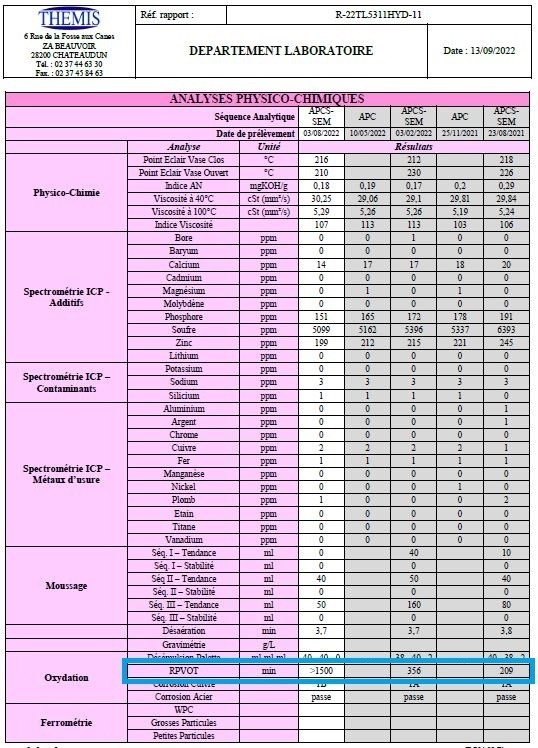

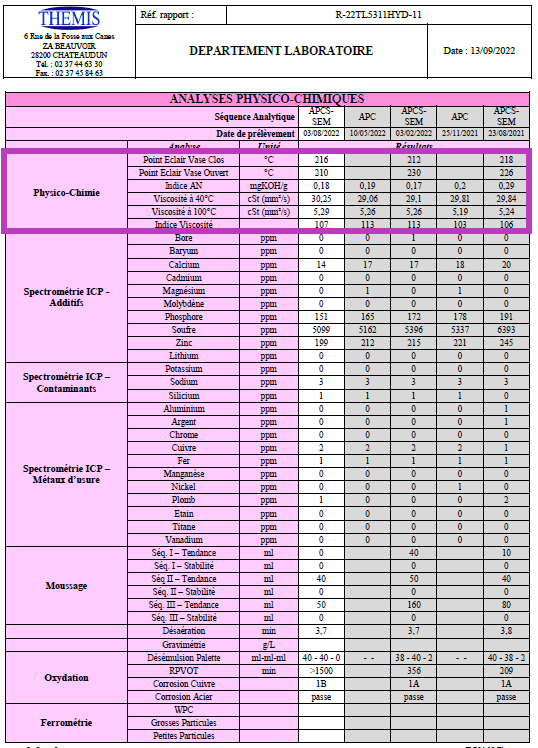

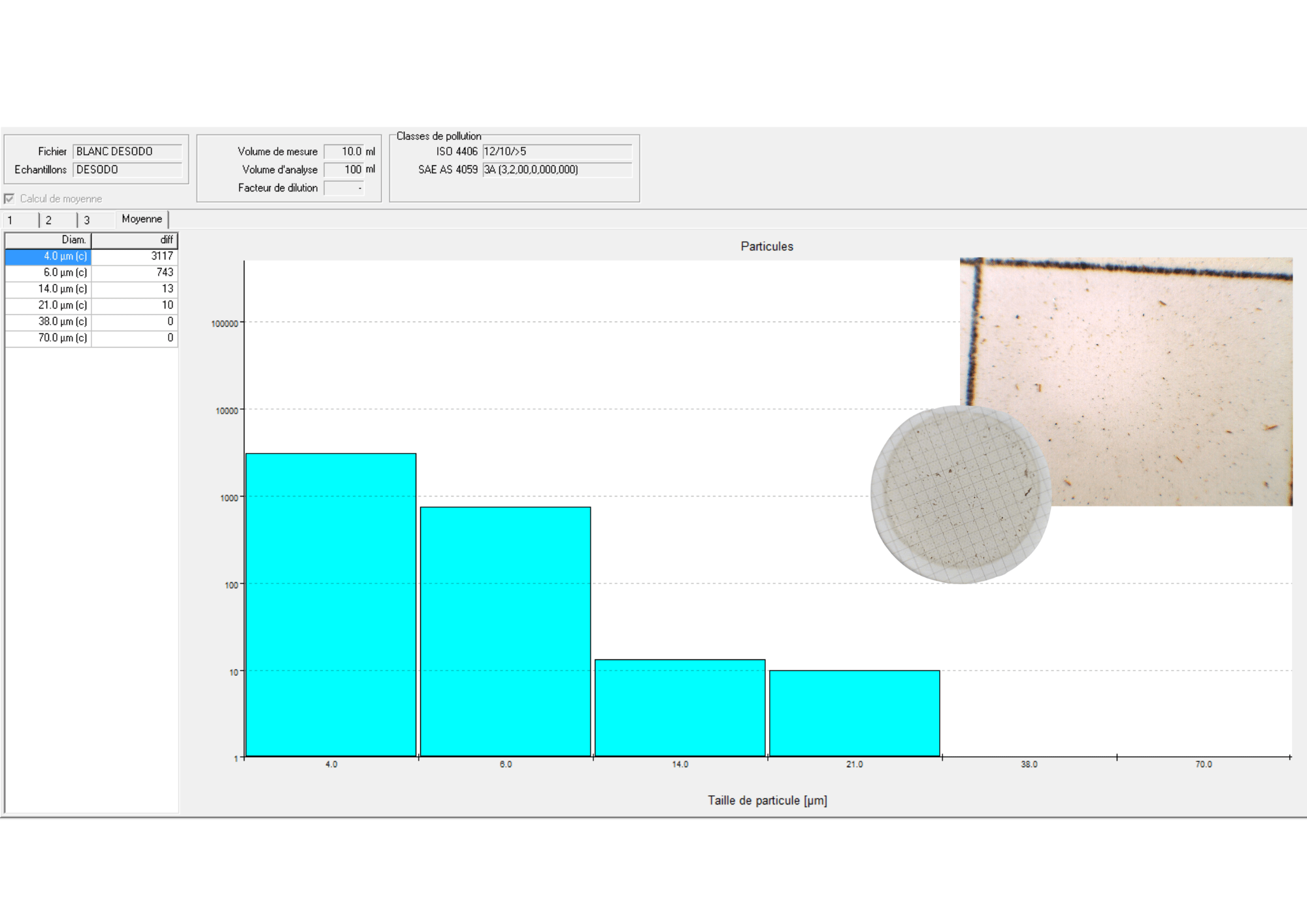

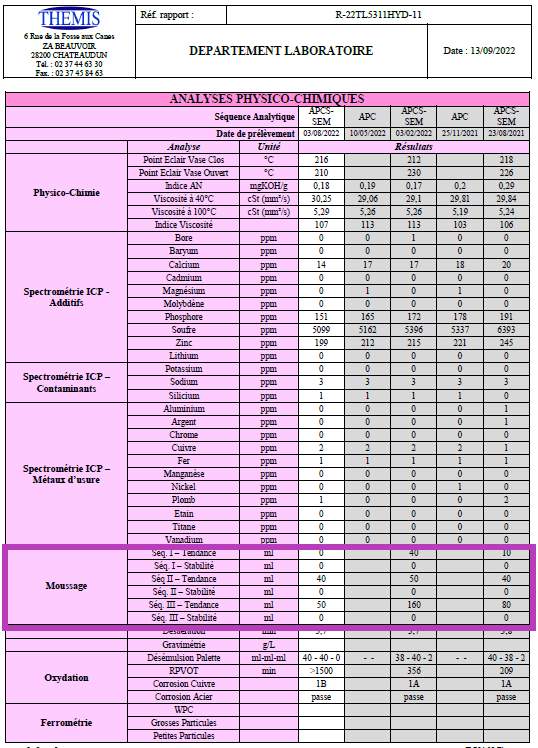

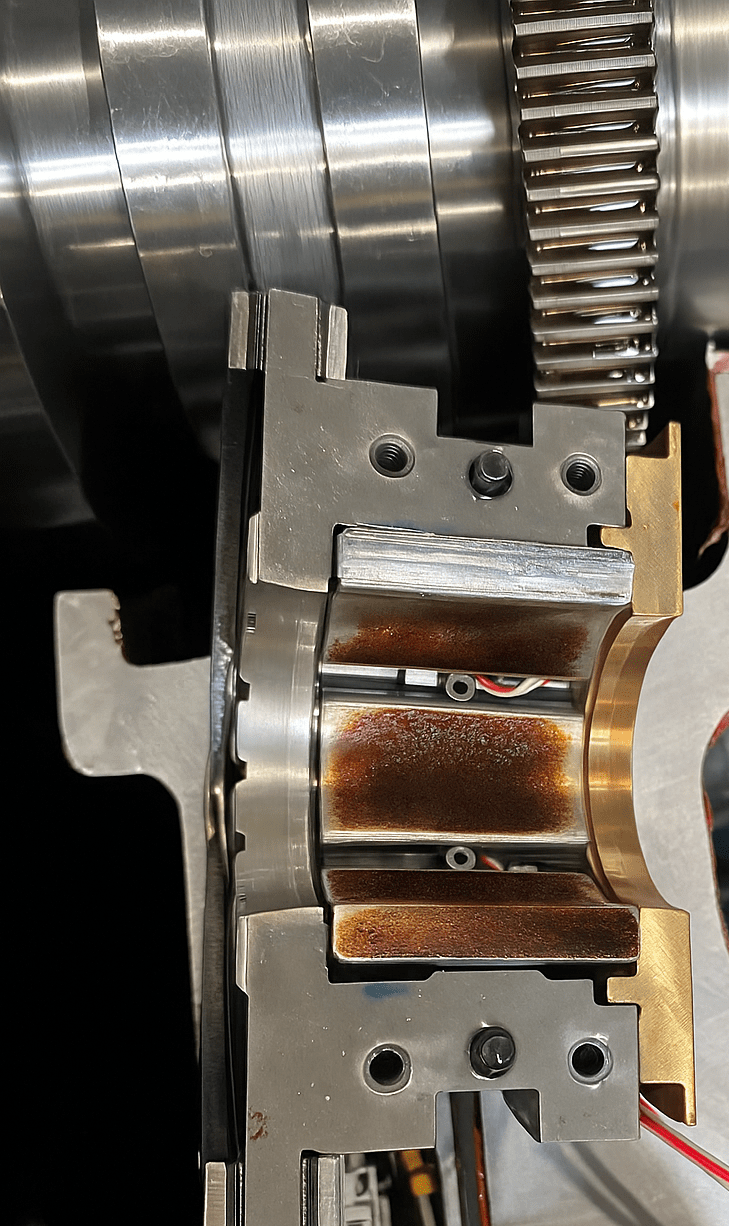

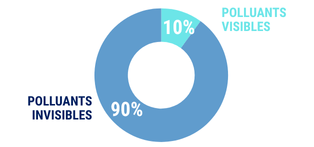

Treated pollutants

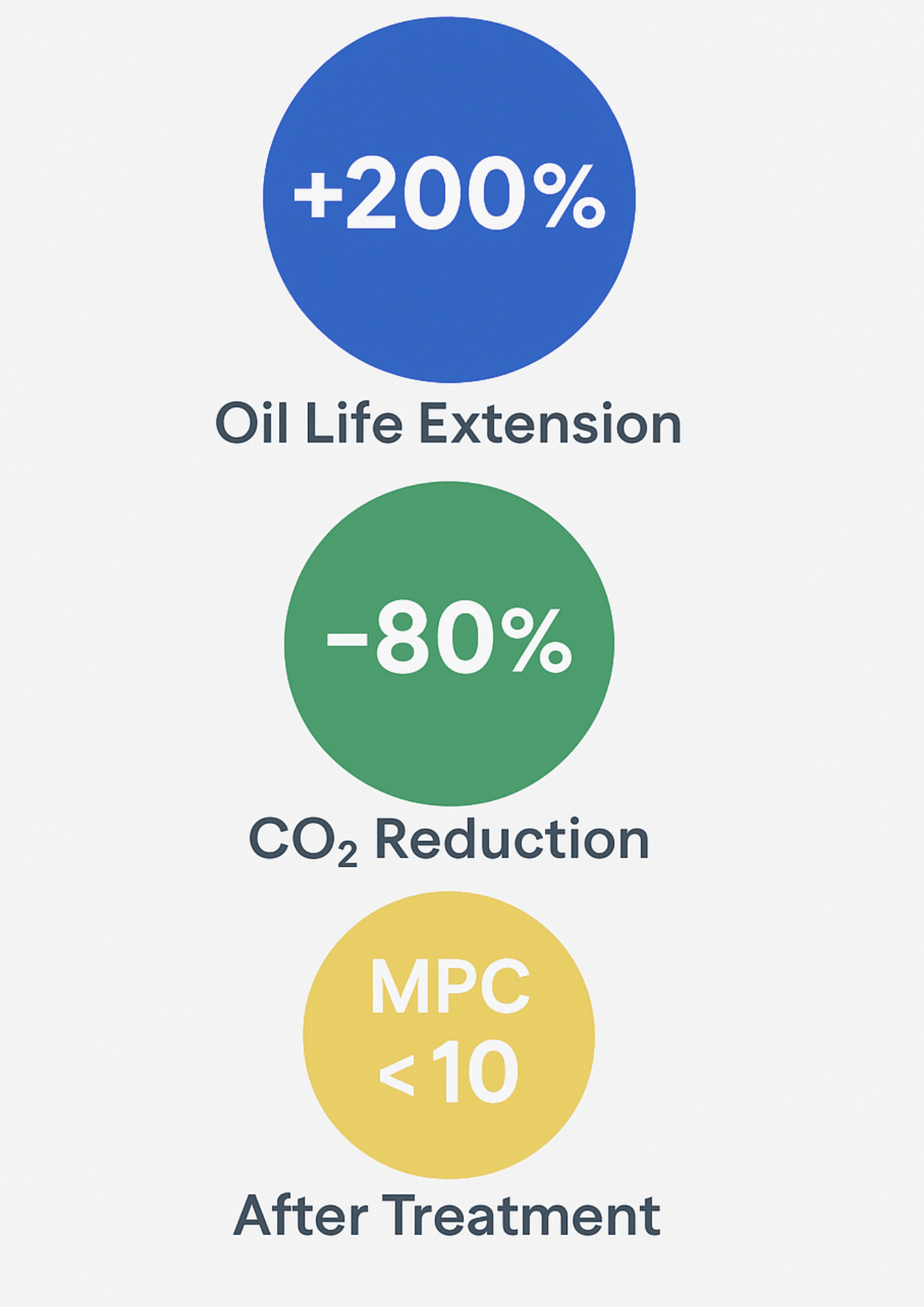

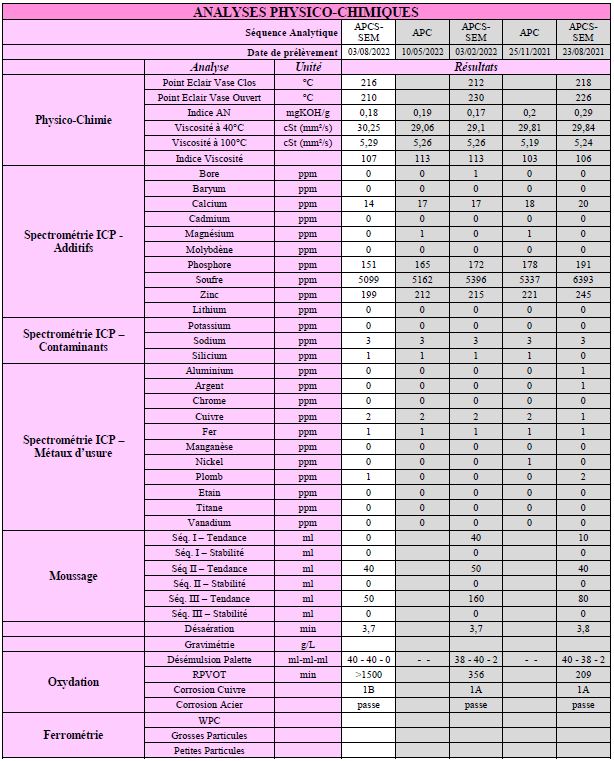

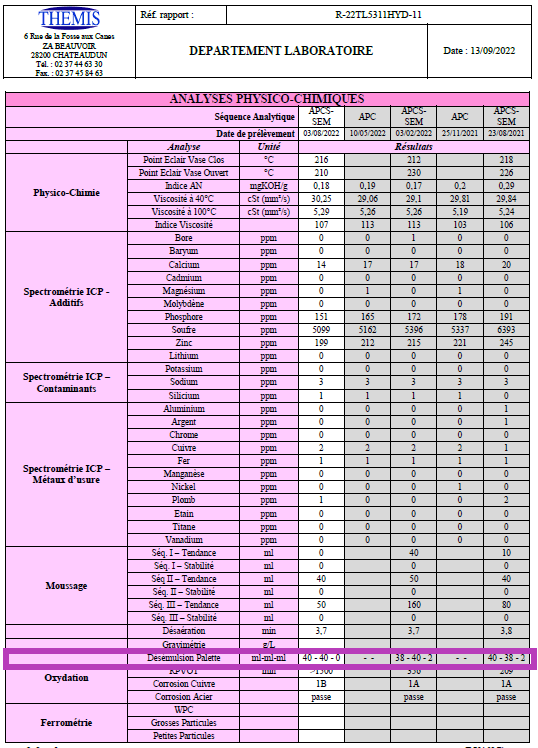

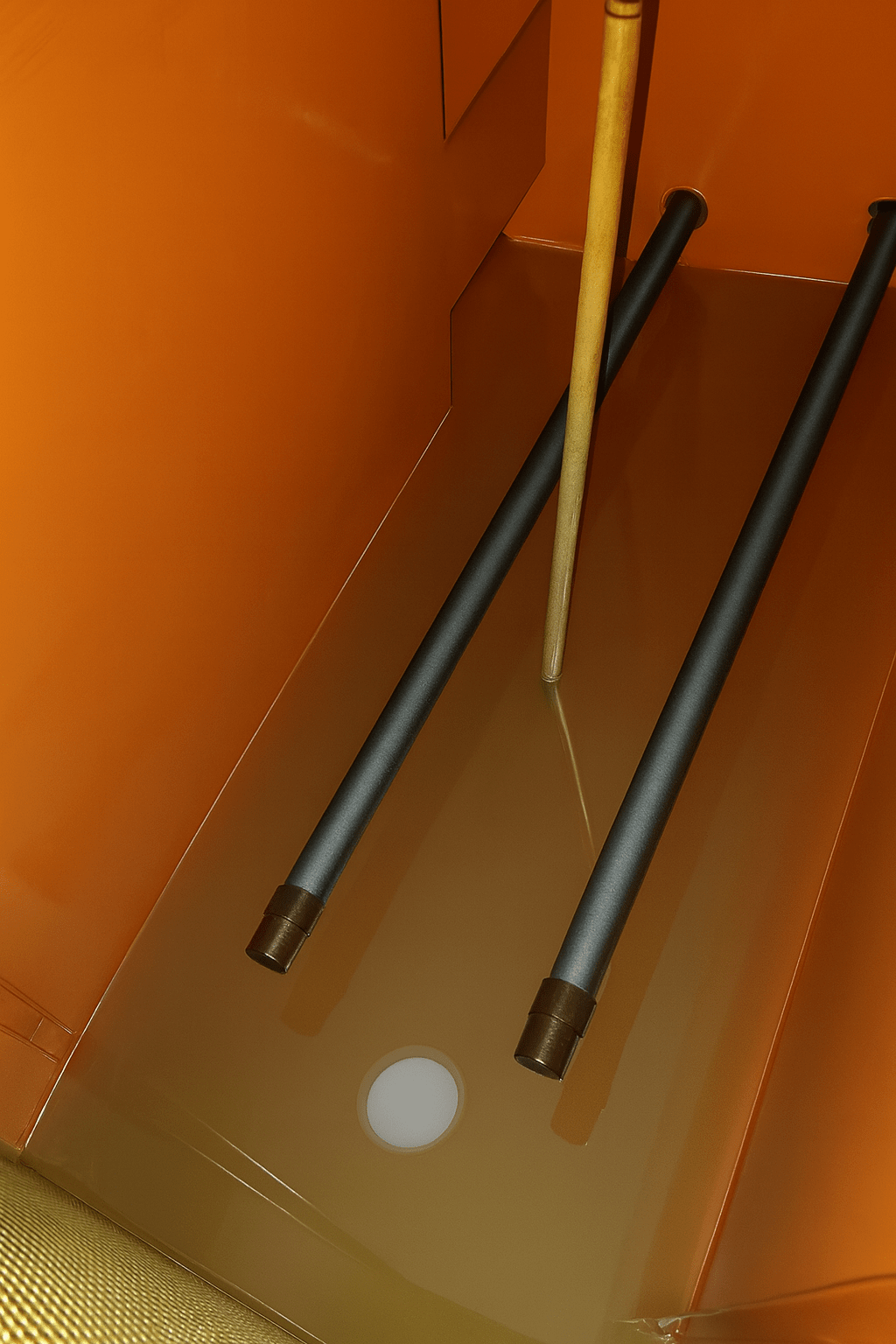

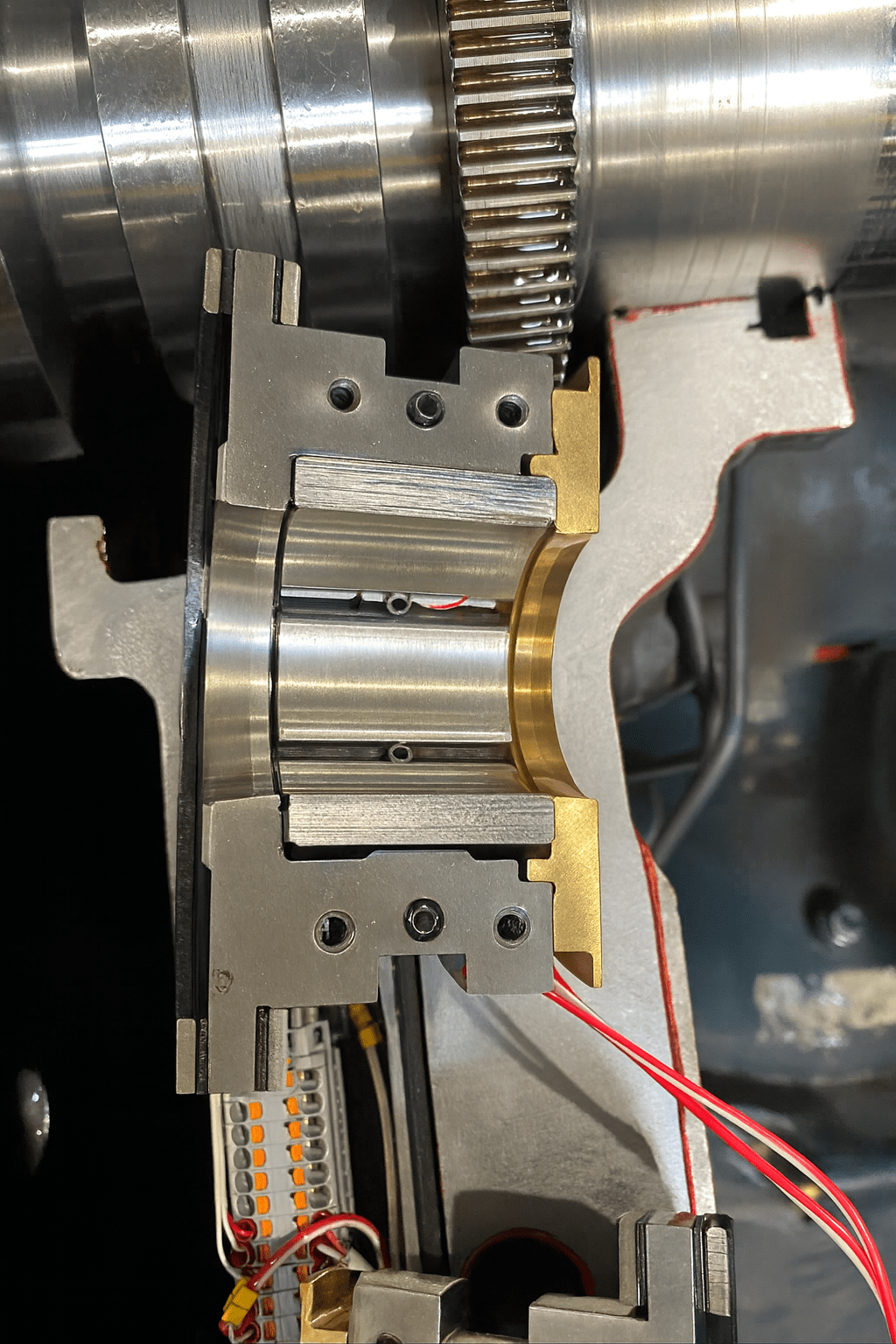

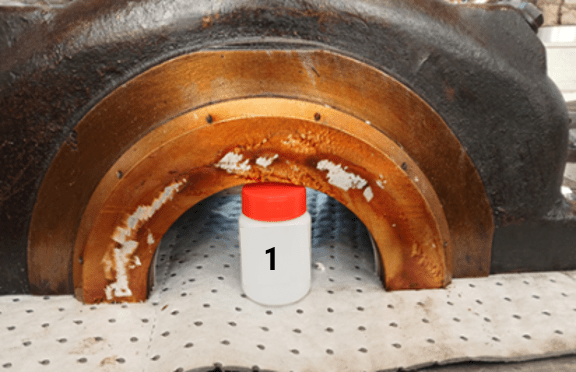

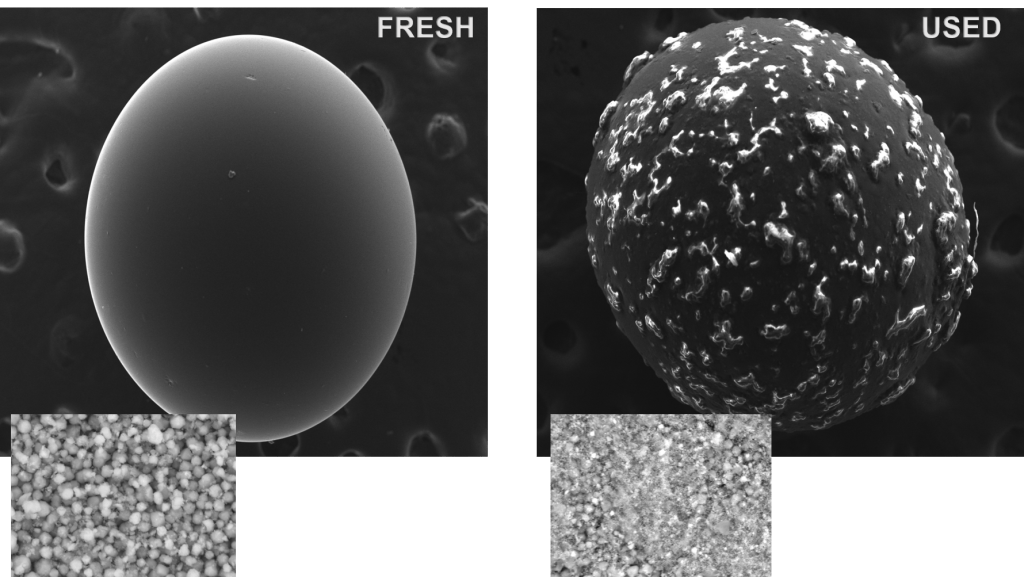

Before treatment

After treatment

(within 2 months)

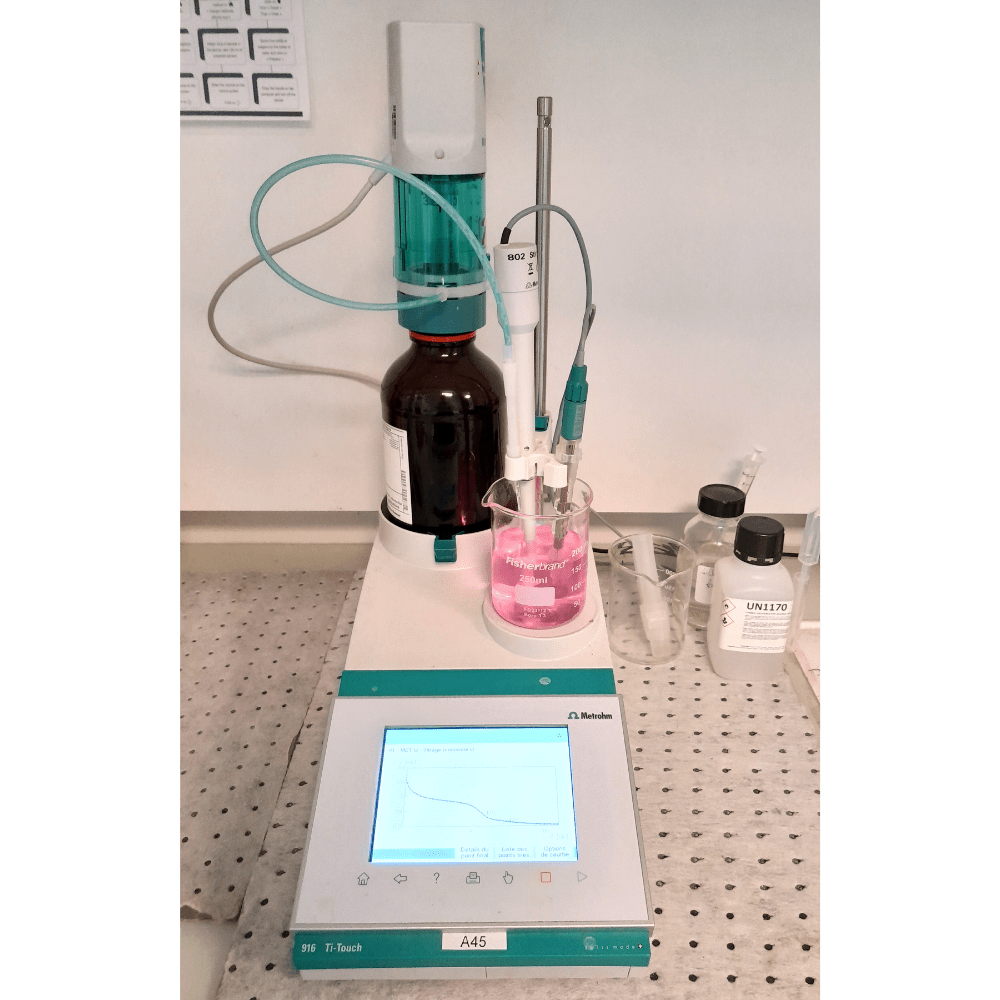

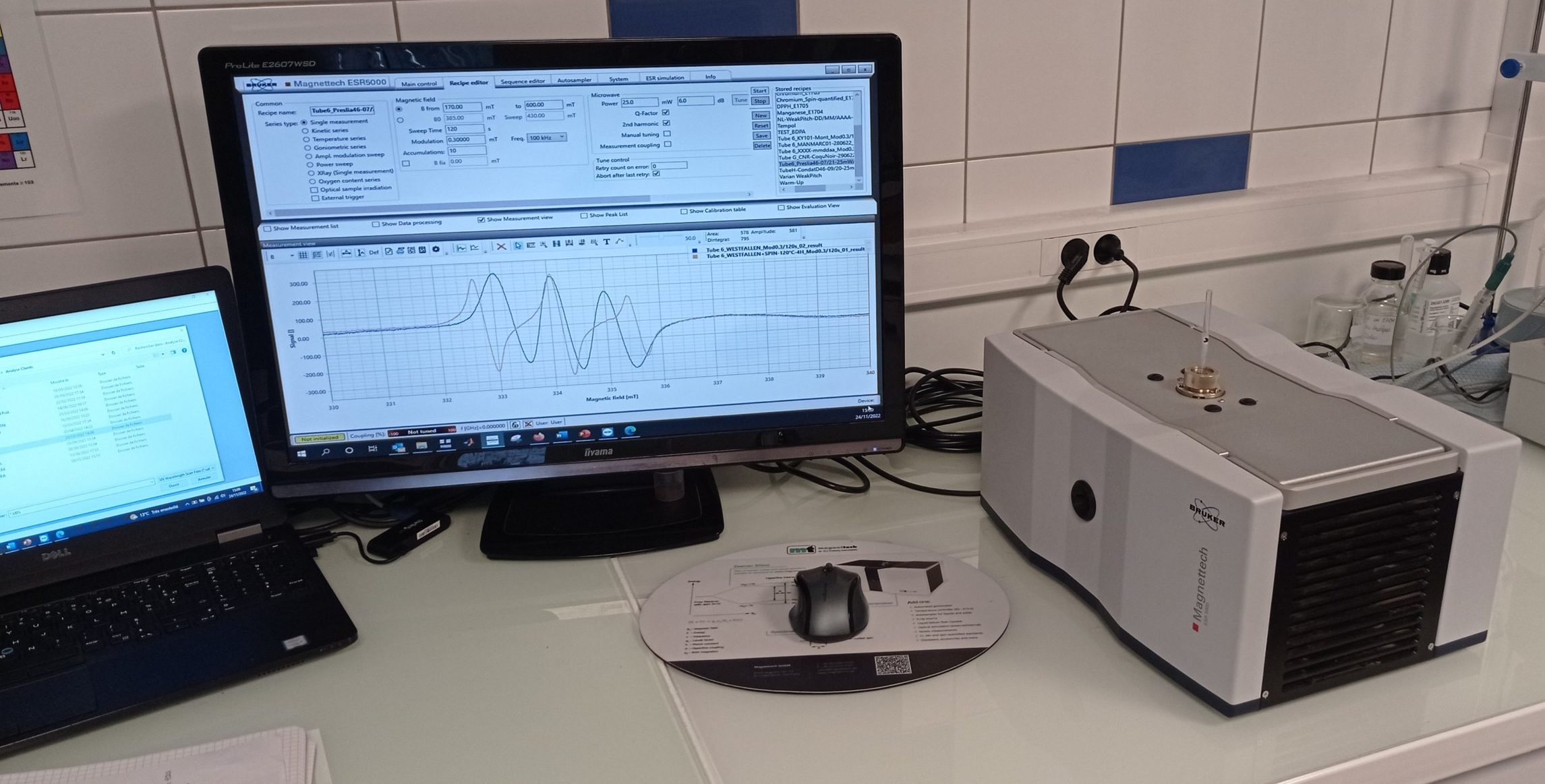

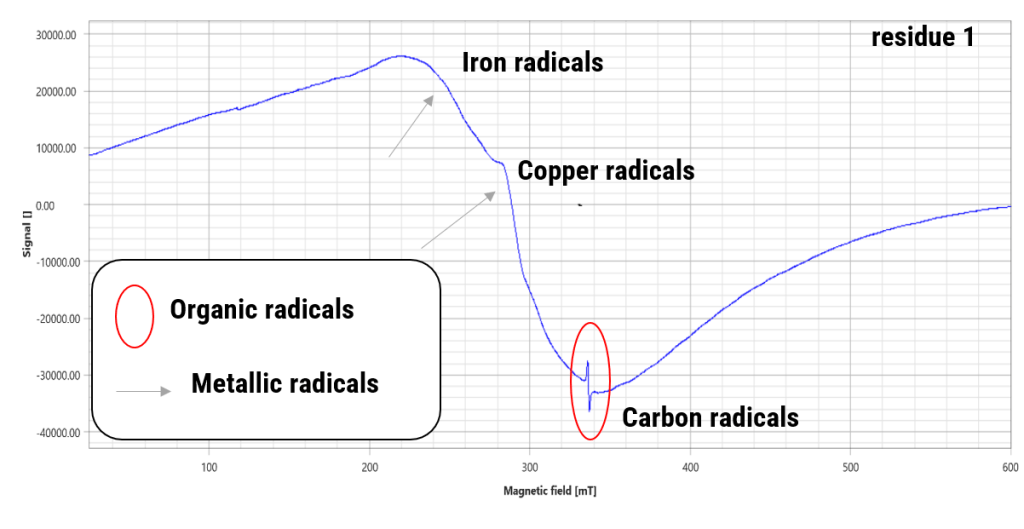

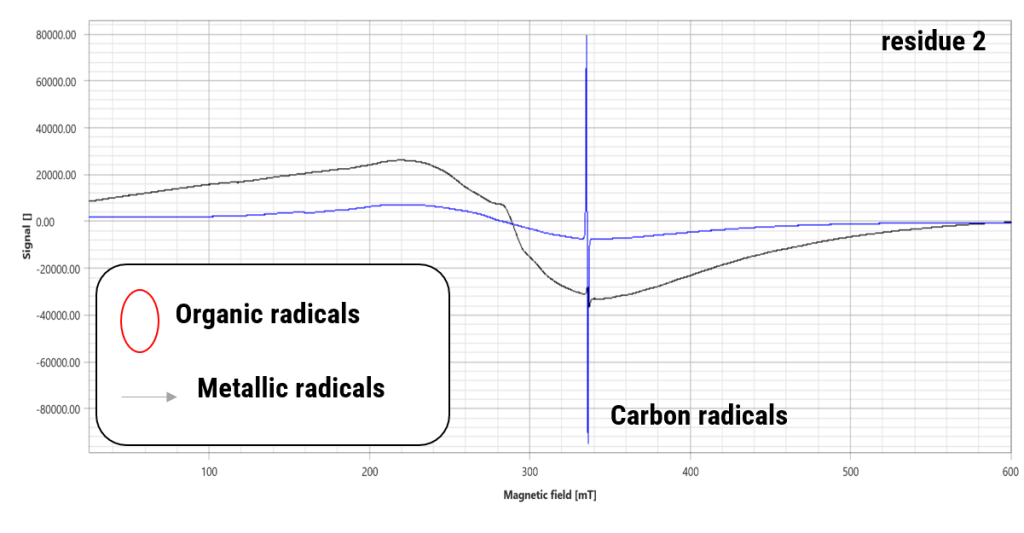

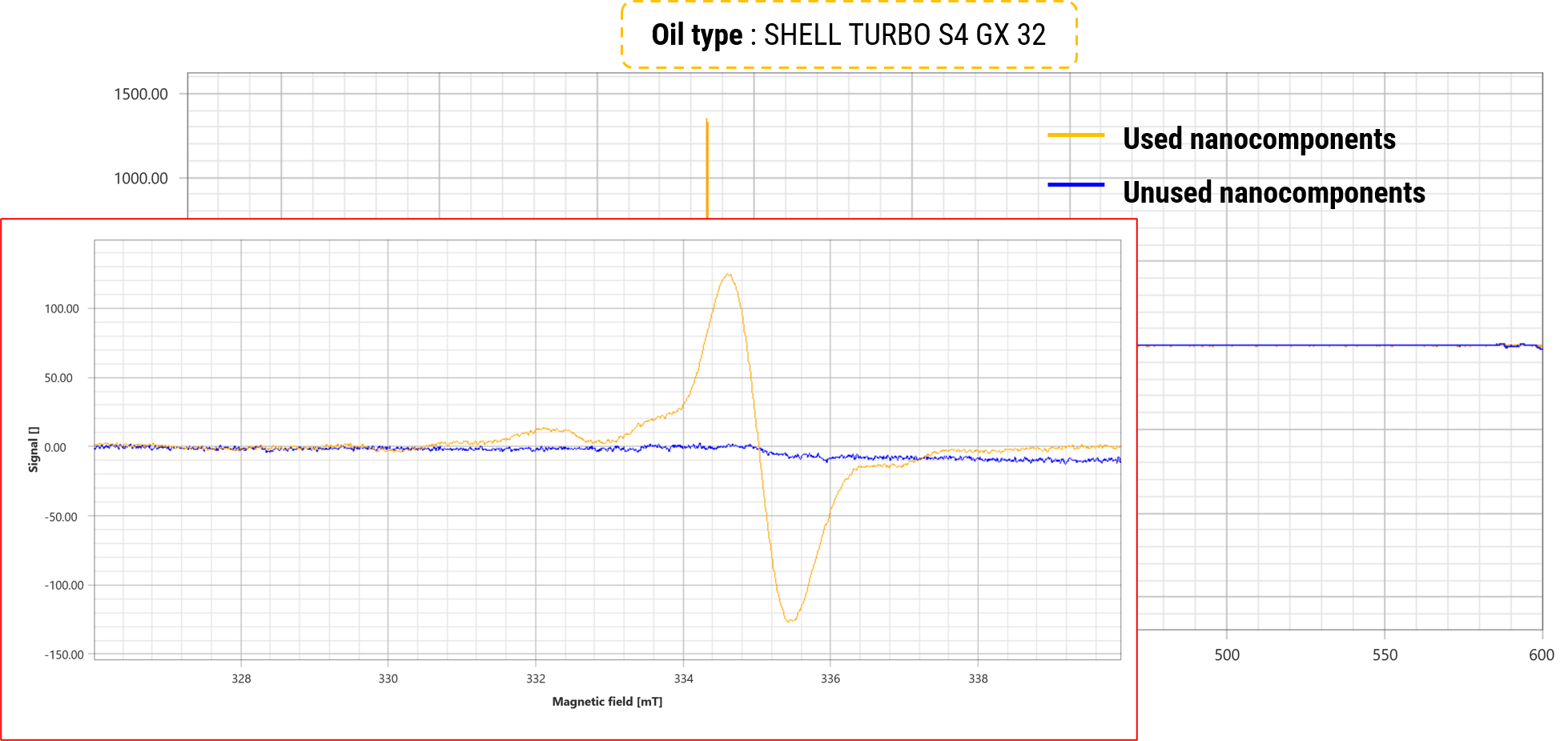

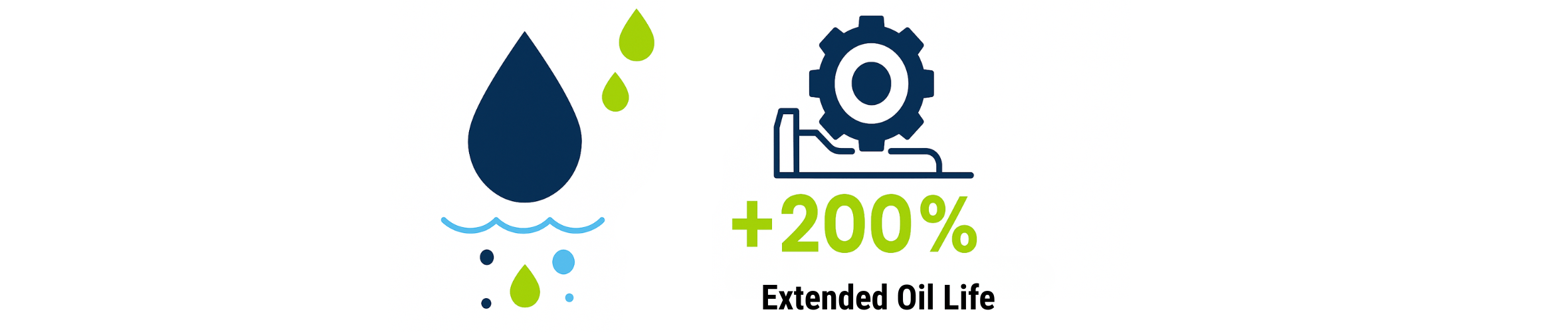

an action chemical targeted to neutralize invisible pollutants such as acids and free radicals

an action chemical targeted to neutralize invisible pollutants such as acids and free radicals