Case Study – Critical Lubricants: Oil Degradation Invisible to Standard Analyses

European Refinery – Turbines & Compressors

Advanced diagnostics (APH membranes / ESR) and Antara solution (AUGEO OIL + TRO Dual system – oil regeneration )

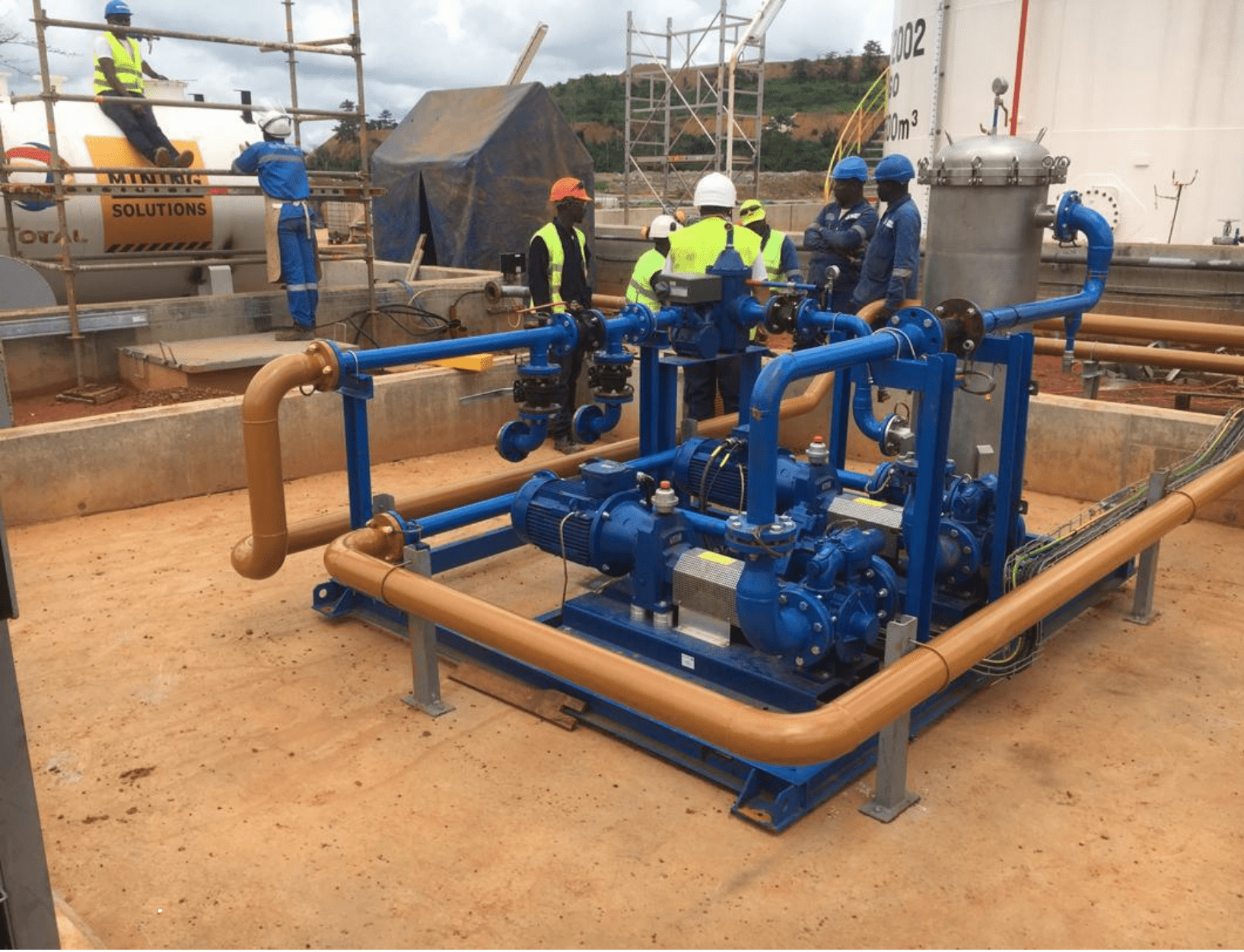

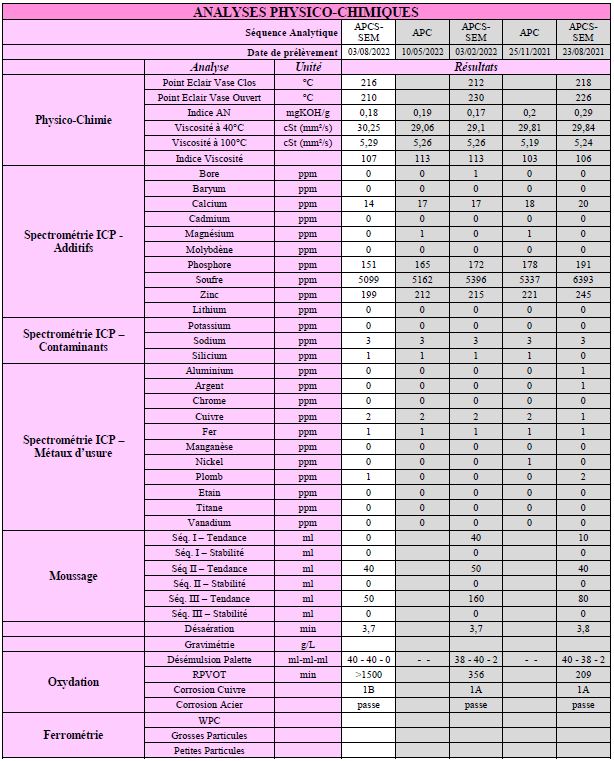

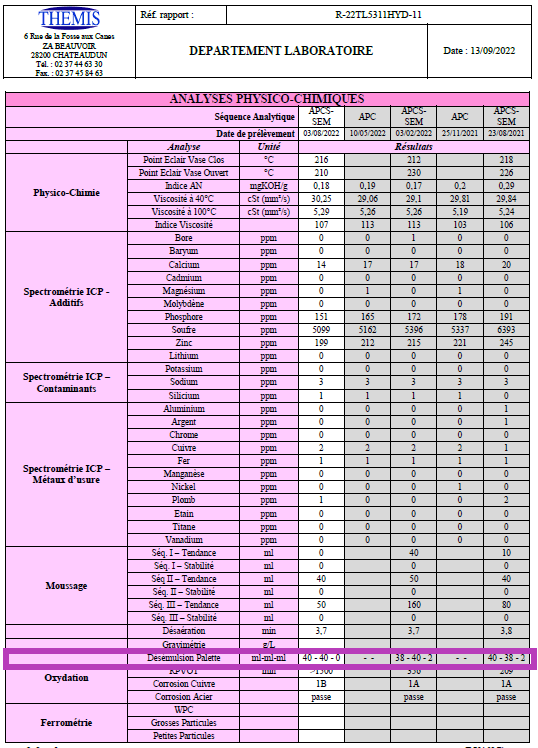

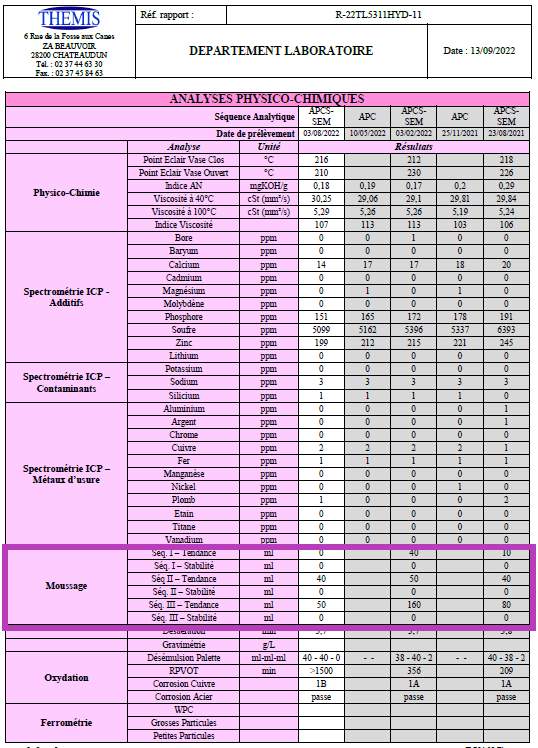

Operator: Large European refinery operating a turbine and two critical process gas compressors.

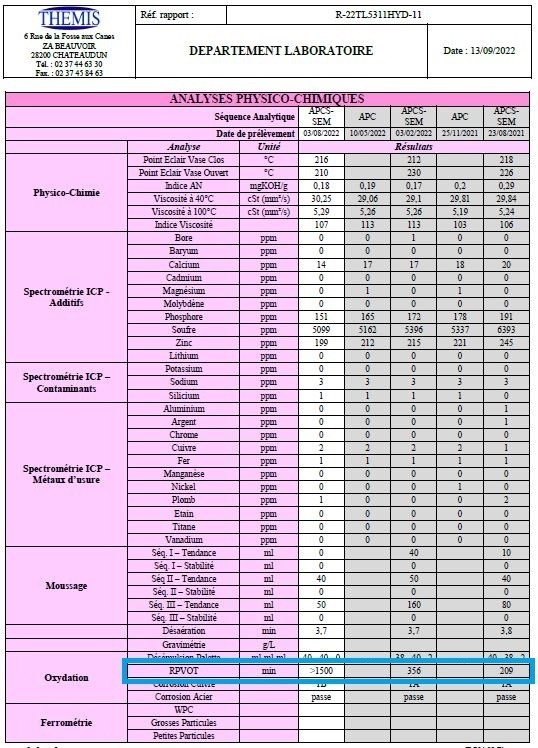

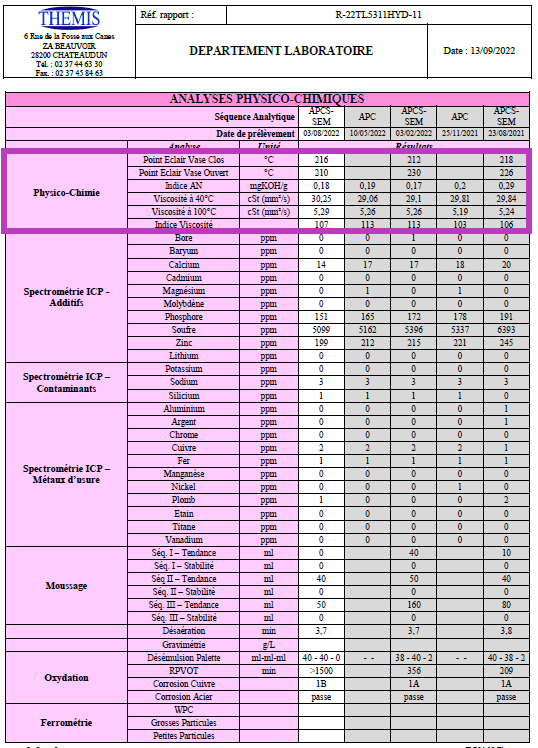

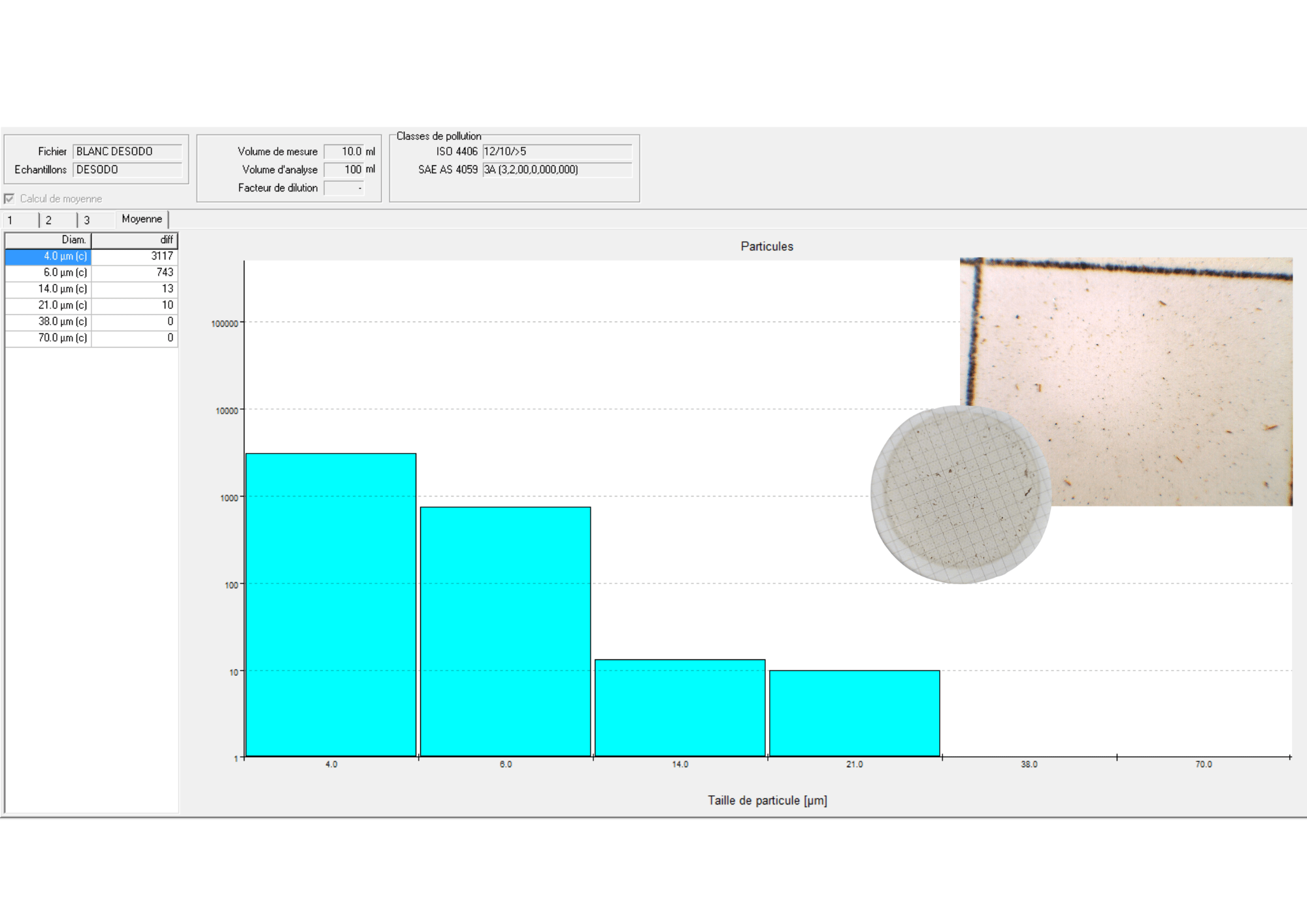

Issue: ISO code drift from 17/16/15 to 20/17/15, initially misinterpreted as particulate contamination.

Internal analyses: MPC = 8, parameters considered acceptable → initial recommendation for a full oil-system flushing.

Objectives: Identify the real root cause, characterize lubricant degradation by-products, avoid heavy flushing, and leverage a reusable case study for other units.

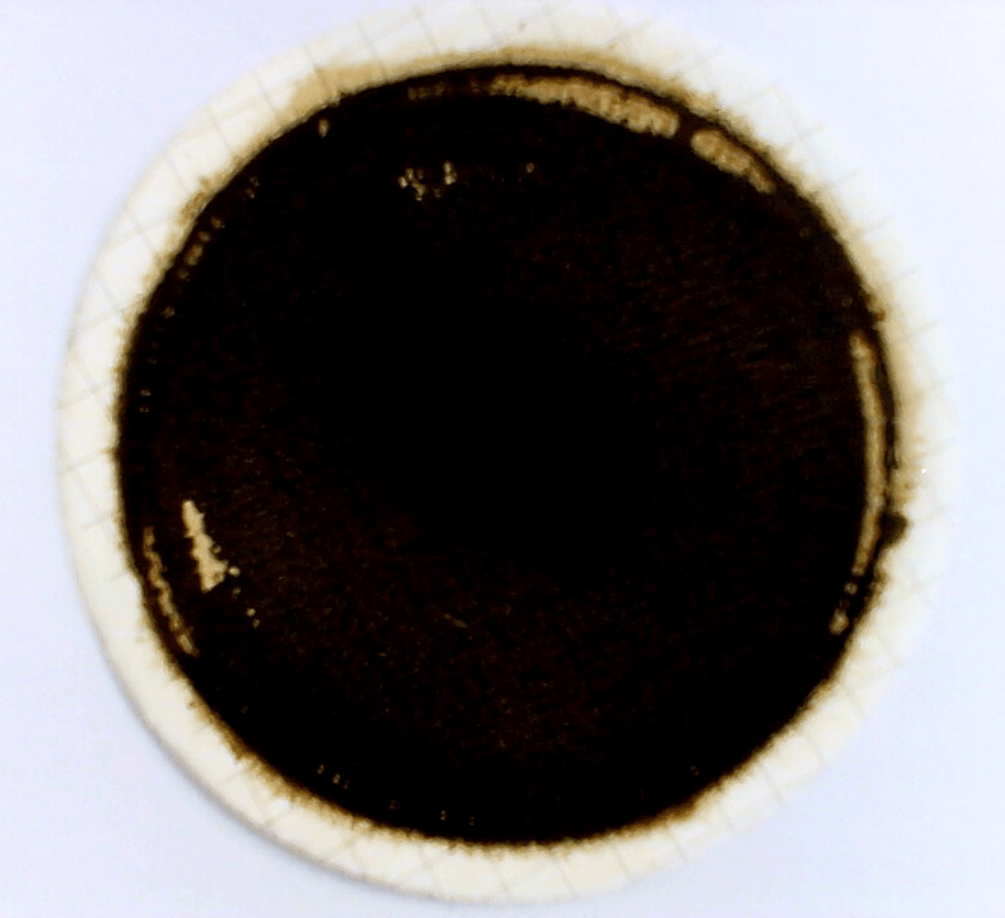

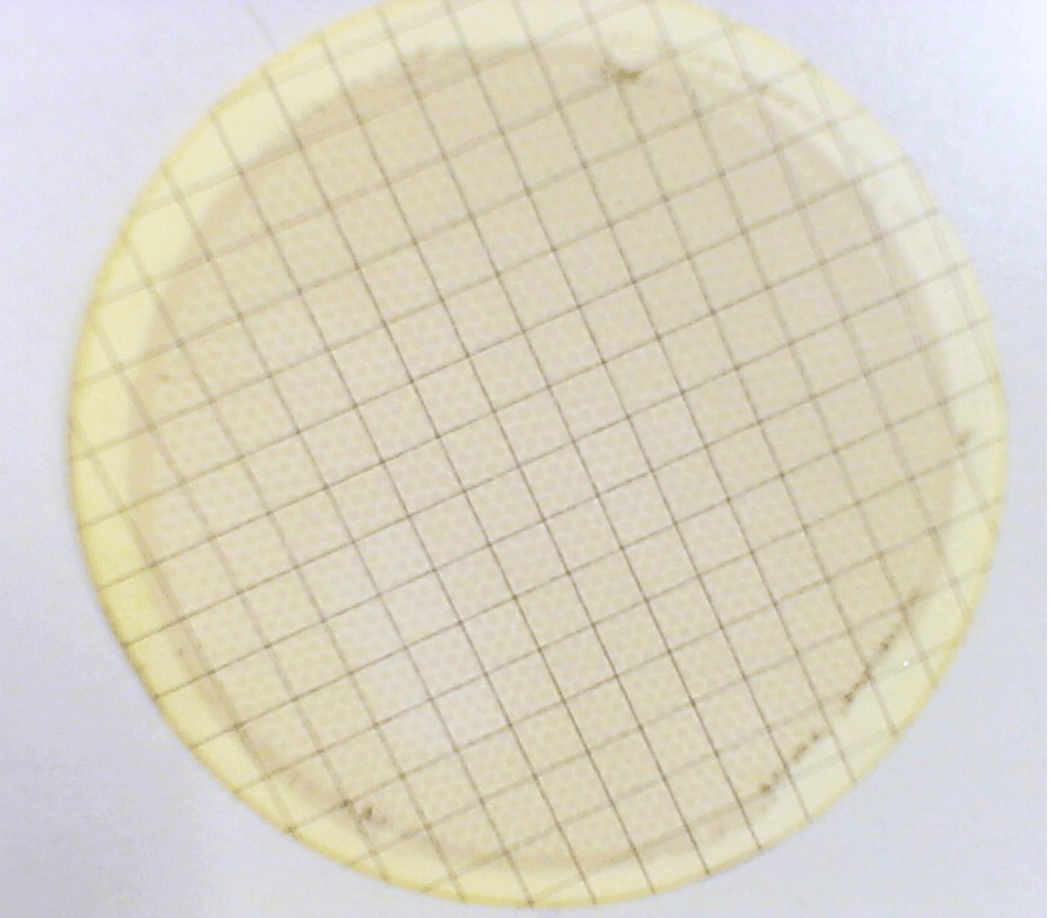

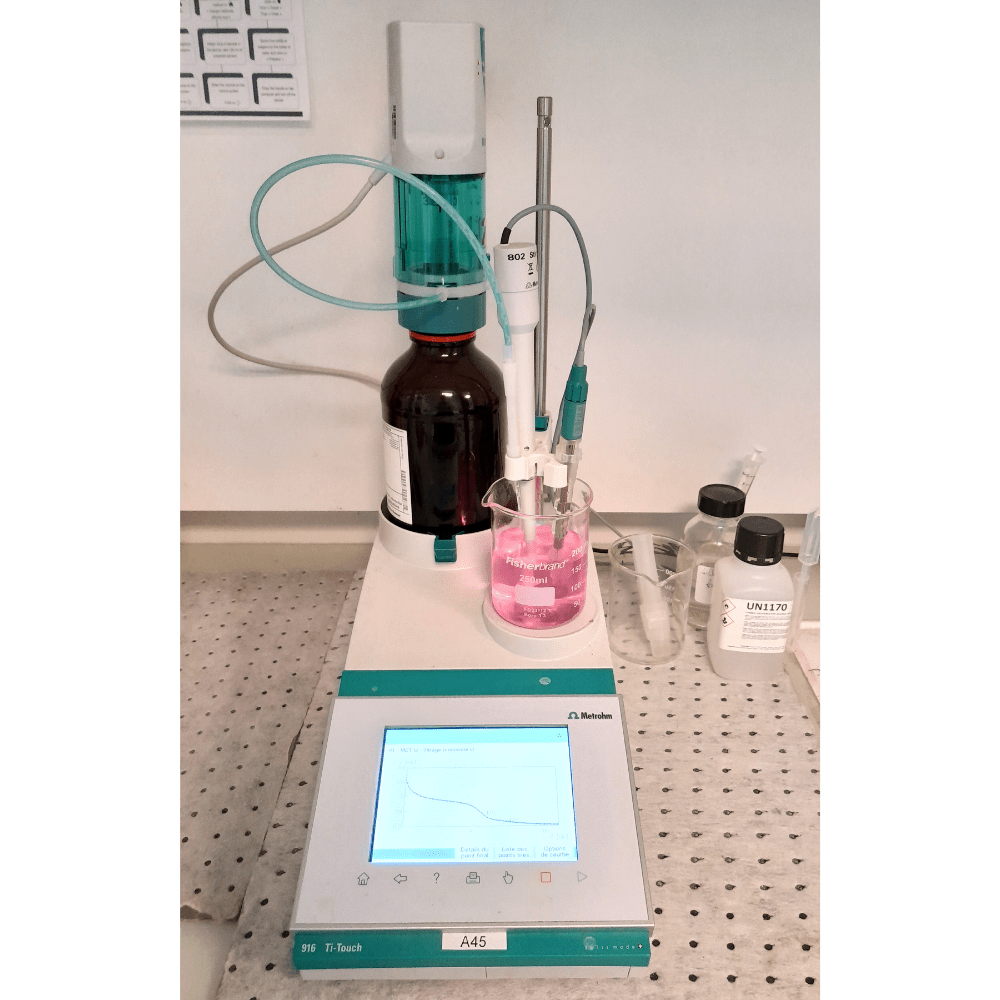

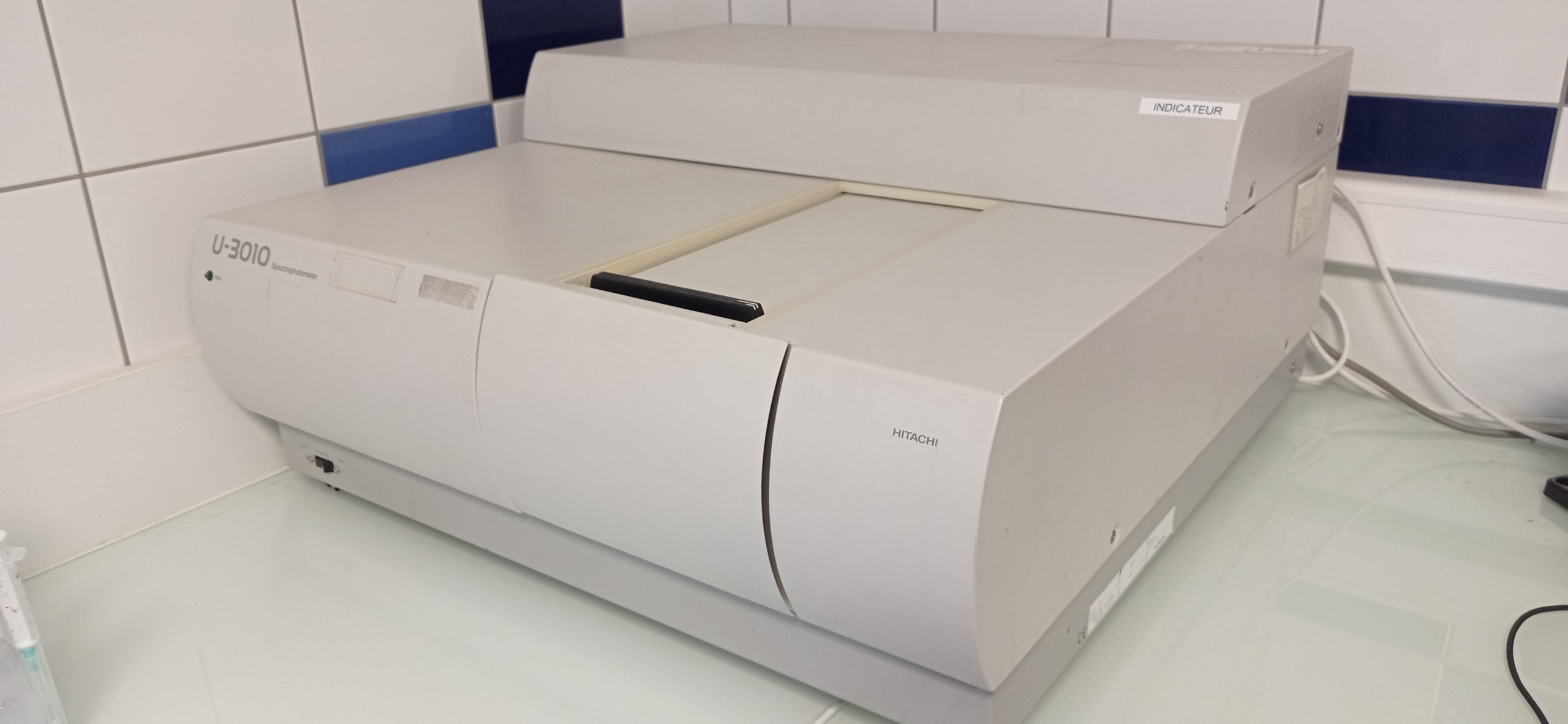

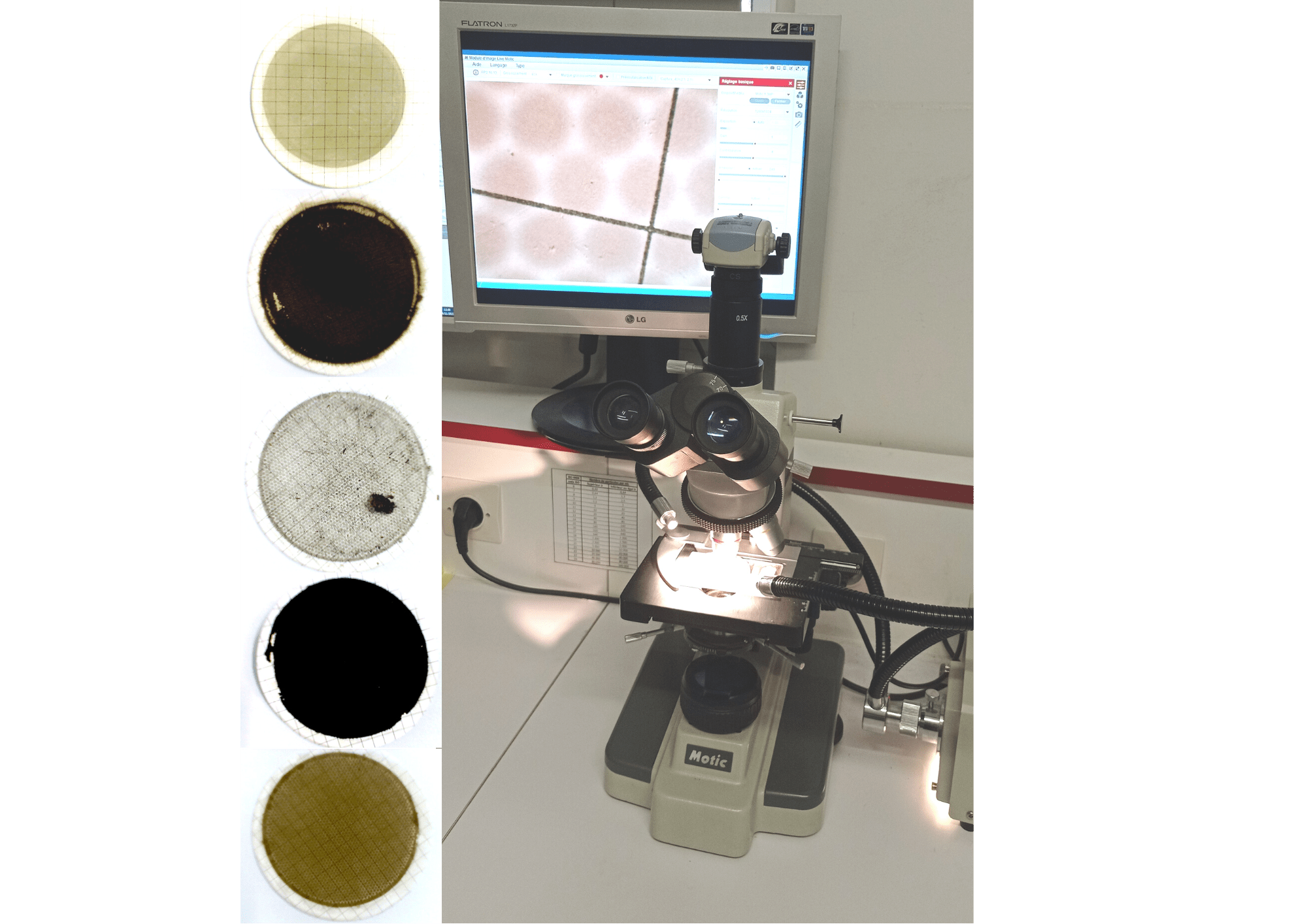

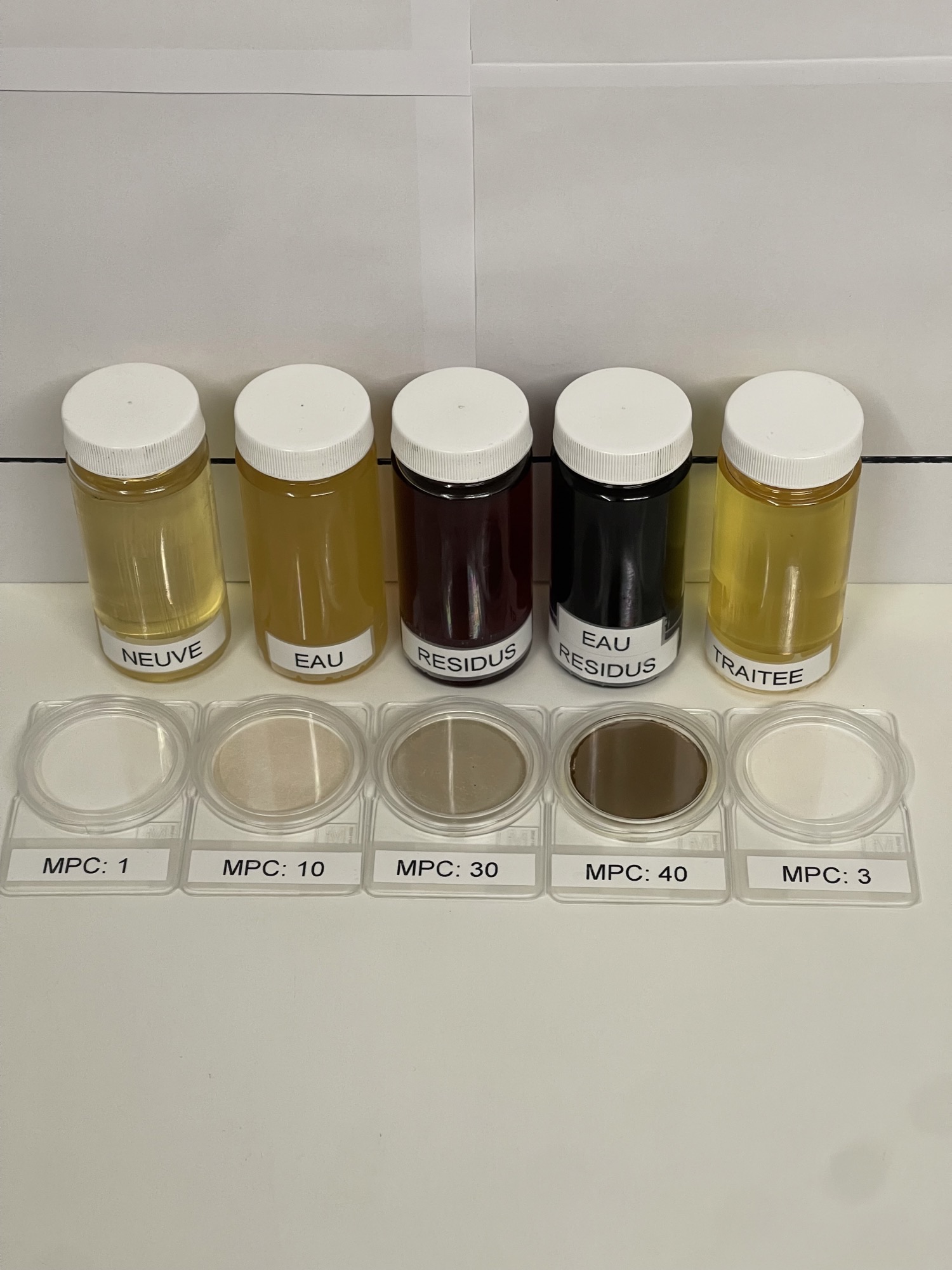

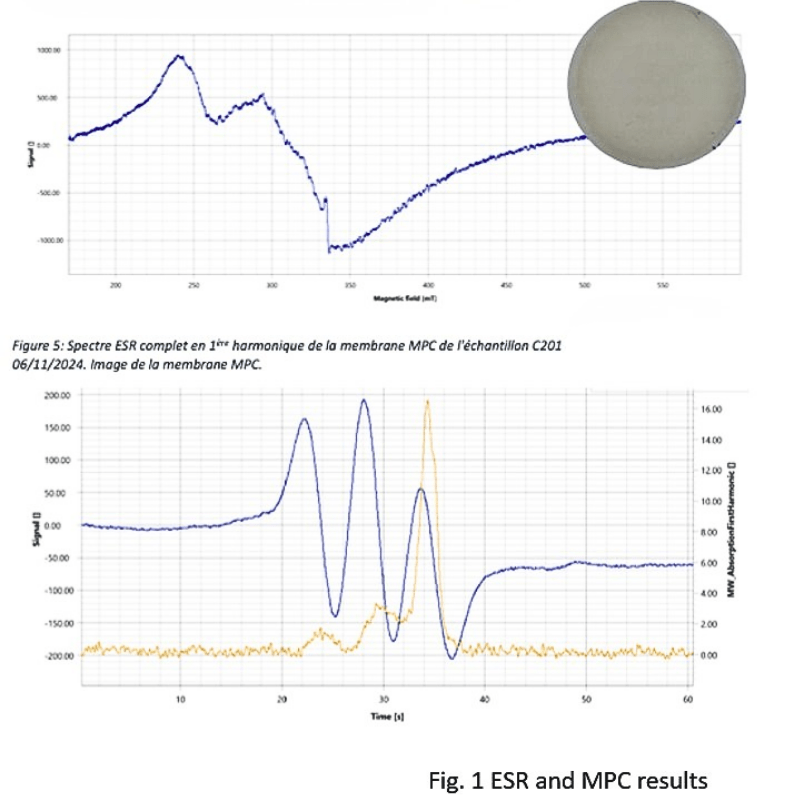

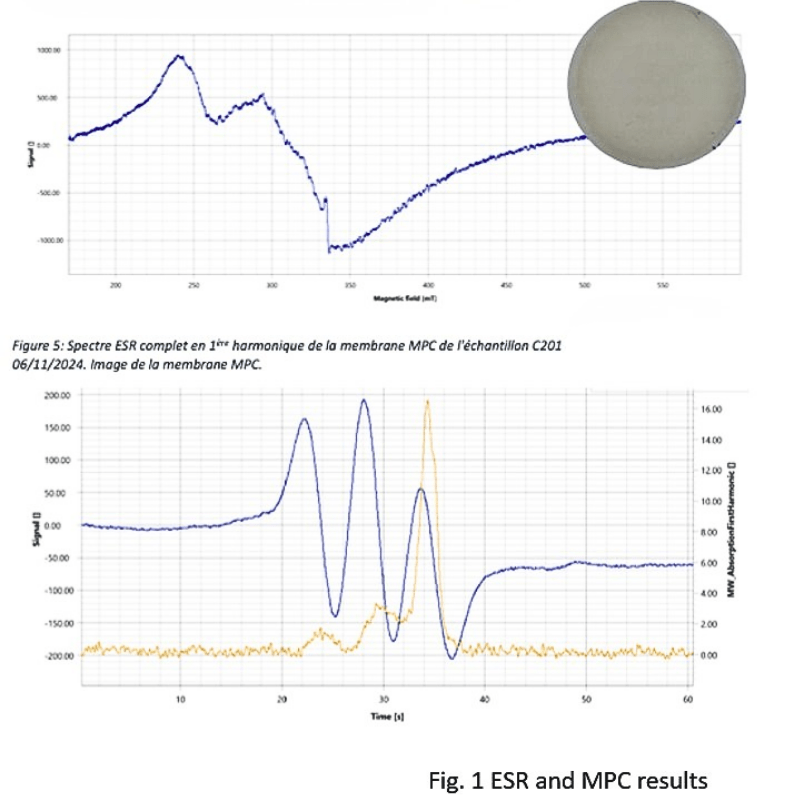

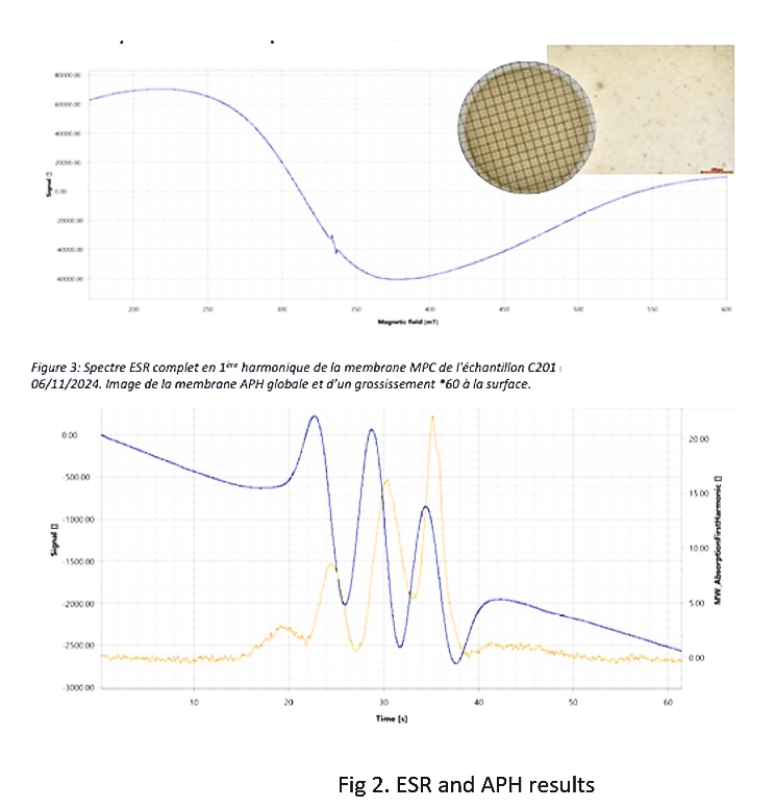

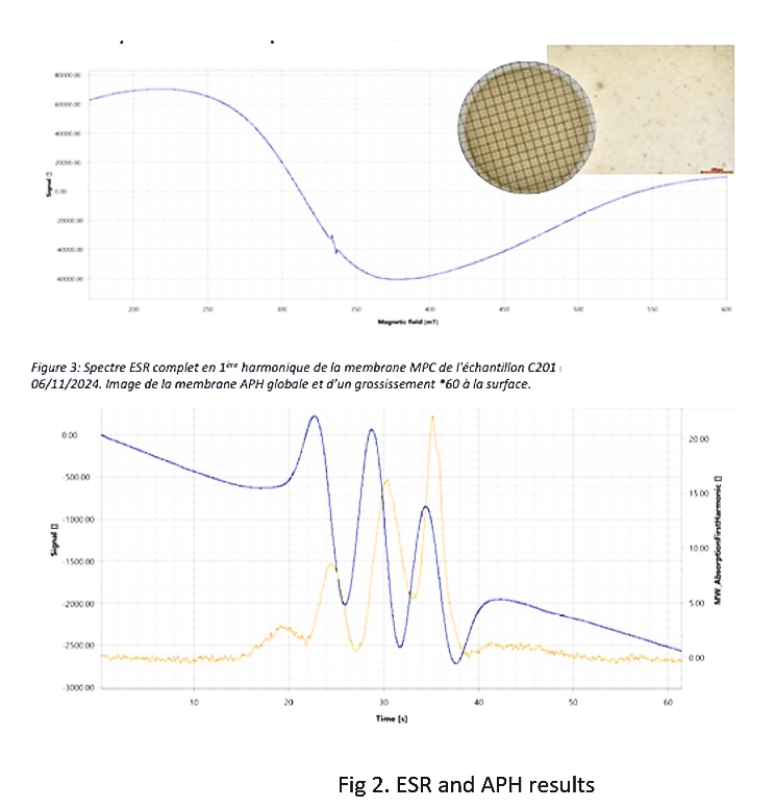

MPC vs APH membranes: revealing polar degradation products

- MPC = 8 → deemed satisfactory.

- APH membranes (0.8 µm, more polar) → strong retention of degradation products.

- Brown–orange, crystalline & gel-like deposits on the APH membrane.

- Resins and polar compounds underestimated by standard MPC evaluation.

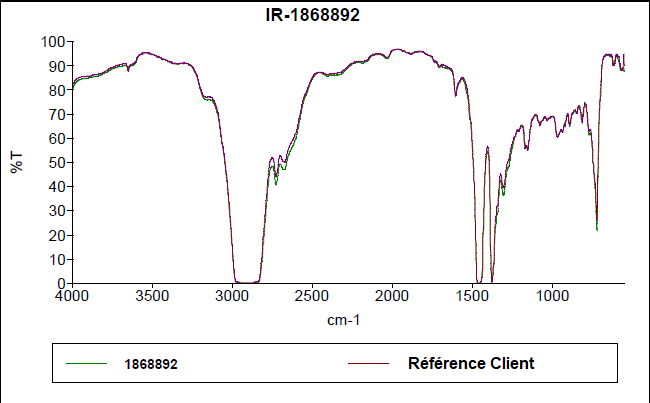

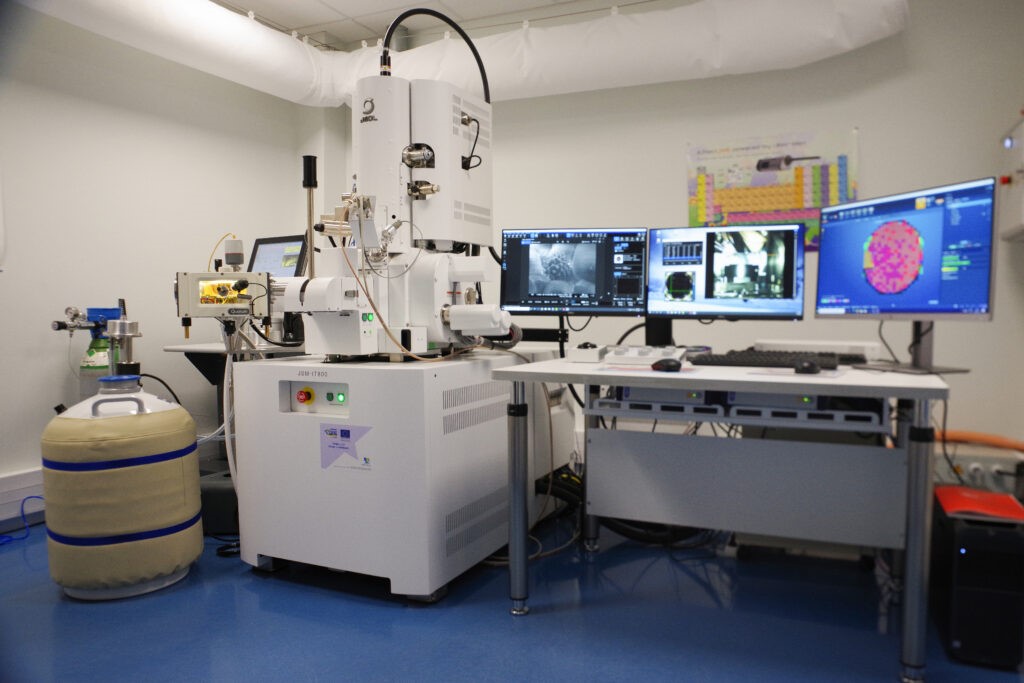

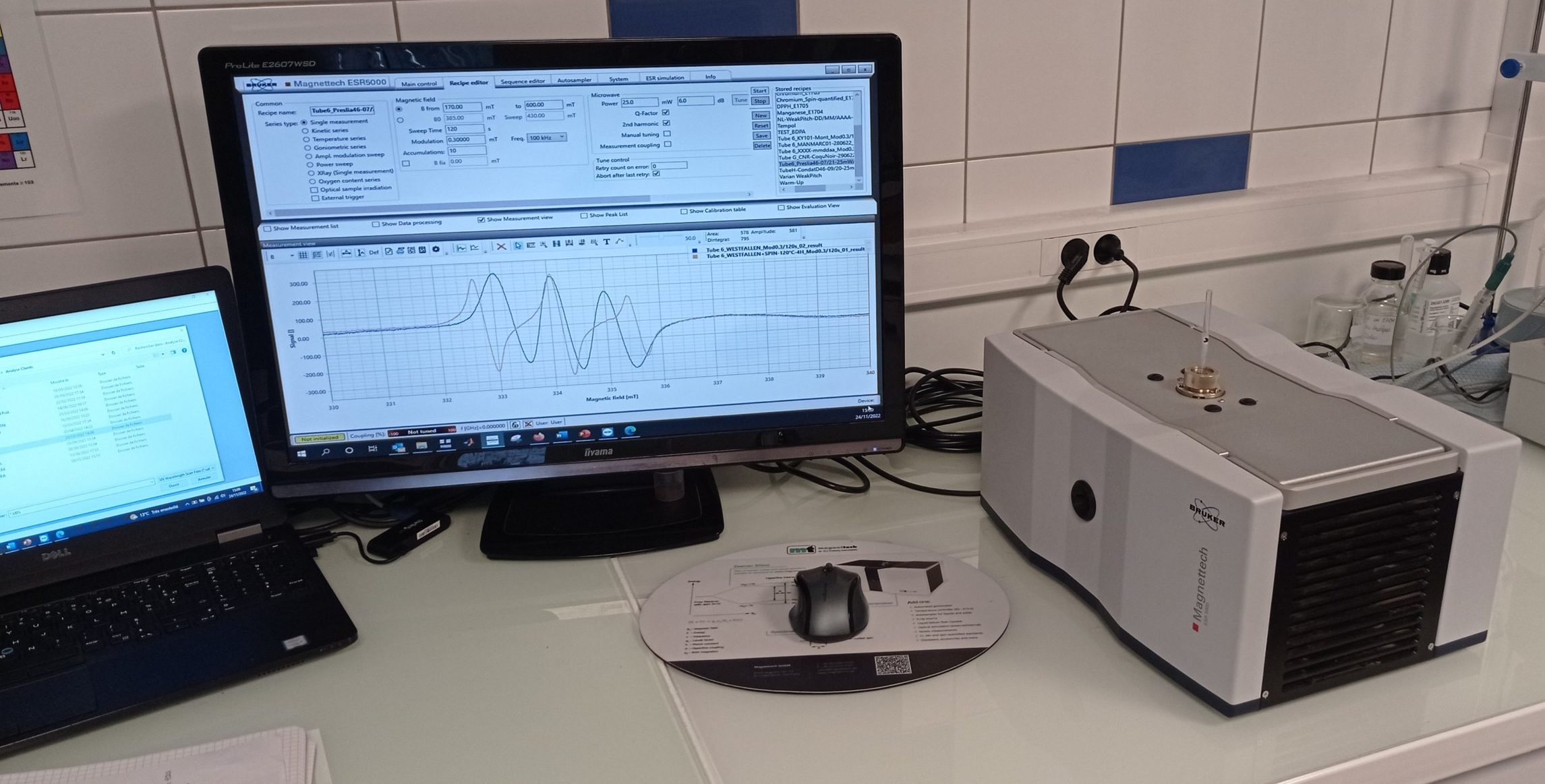

Aminyl radicals & copper complexes

- Aminyl radicals: advanced degradation of amine antioxidants.

- Copper complex detected by ESR but not visible by ICP (ppb-level presence).

- Confirmation of a copper alloy in the circuit, acting as a catalyst for radical reactions.

AUGEO OIL – targeted cleaning

- Solubilization of polar degradation products and resins responsible for deposits.

- Cleaning internal deposits in the turbine and compressors.

- Neutralization of the most reactive degradation species.

This curative phase restores a clean and stable baseline before implementing continuous regeneration with TRO systems.

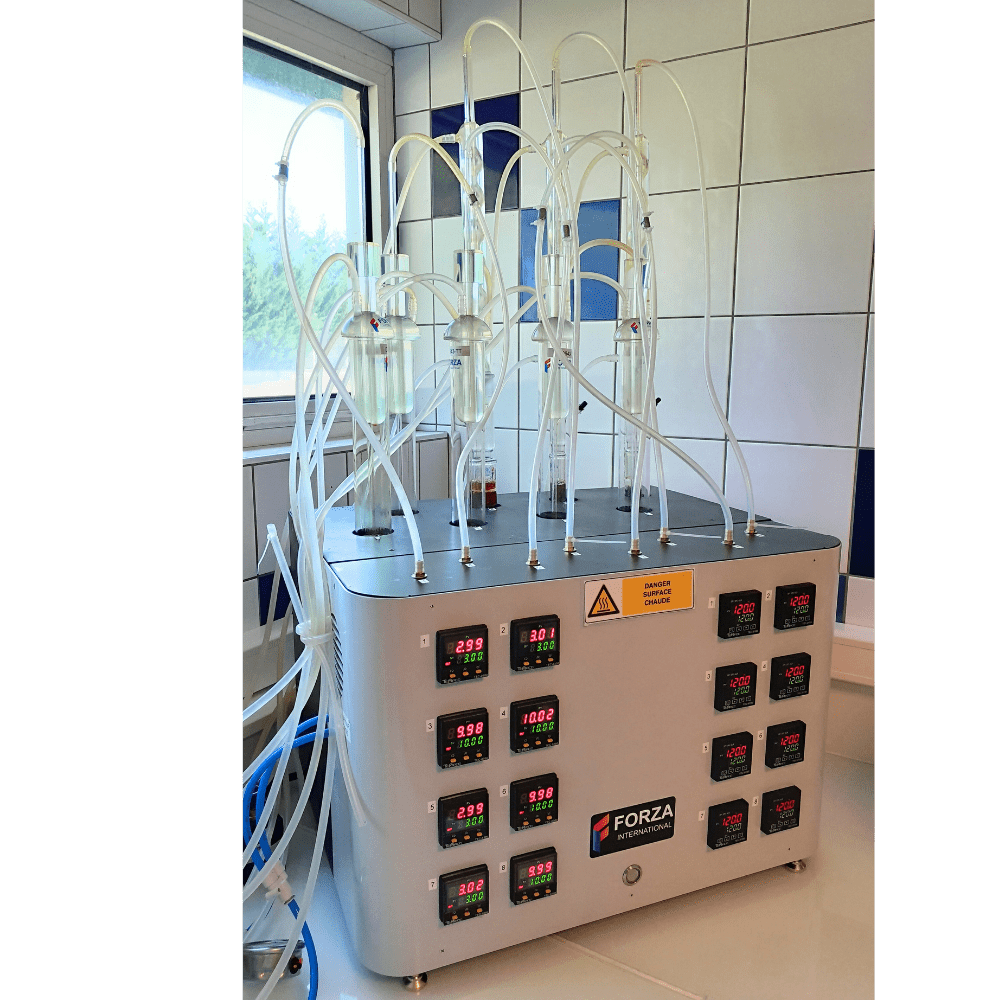

Continuous regeneration with the TRO Dual system

- Continuous removal of polar degradation products and their precursors.

- Reduction of radicals that accelerate oil oxidation.

- Limitation of catalytic effects from trace copper species.

- Long-term stabilization of the lubricant and its antioxidant package.

The operator shifts from one-off treatments to a proactive oil health management, leveraging the Antara TRO Dual system.

- Significant reduction of resinous and gel-like deposits in the oil system.

- Long-term stabilization of the antioxidant package and lubricant chemistry.

- Improved ISO cleanliness without performing a full flush.

- Longer oil life and reduced consumption.

- Increased availability of critical turbines and compressors.

Benefits for the operator

- Fewer unplanned stops related to lubrication issues.

- Stabilized operational performance on critical equipment.

- Secured operational continuity, independent of supply chain disruptions.

Benefits for maintenance and reliability

- Full flushing avoided (time, budget, and risk savings).

- Reduced corrective interventions on the oil system.

- Team capability upgrade through advanced diagnostics (APH membranes, ESR).