We're delighted to share with you our appearance on BFM Business in FOCUS PME, where we had the opportunity to present our expertise and research in the field of oils, fuels and their monitoring and degradation treatment. It was an enriching and exciting experience!

Jérémy Pallas (Themis) : Themis est un fabricant de solutions de filtration – 08/07 (bfmtv.com)

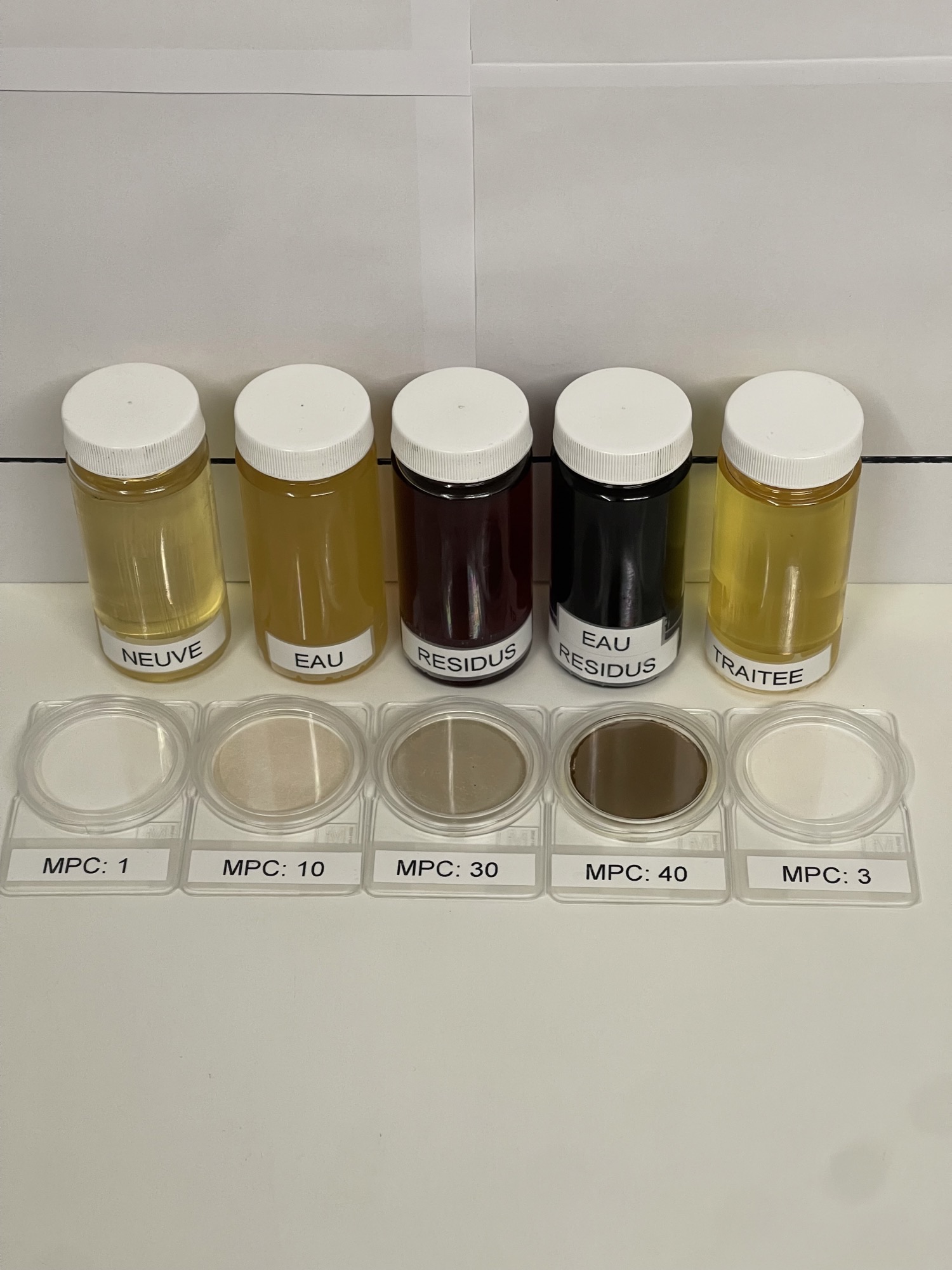

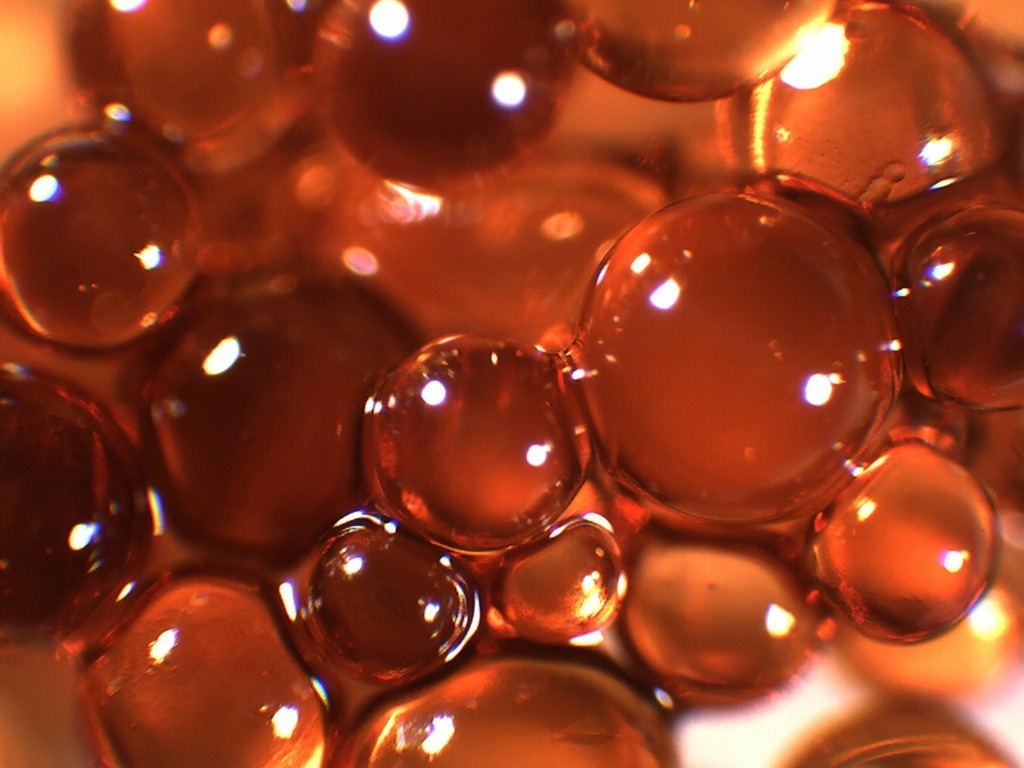

Lors de cette entrevue, nous avons discuté des innovations que nous avons apportées dans le domaine de la filtration des fluides organique et comment elles ont un impact significatif sur l’industrie. Nous avons également partagé notre vision stratégique pour l’avenir, mettant en évidence notre engagement envers la croissance durable et l’excellence opérationnelle.

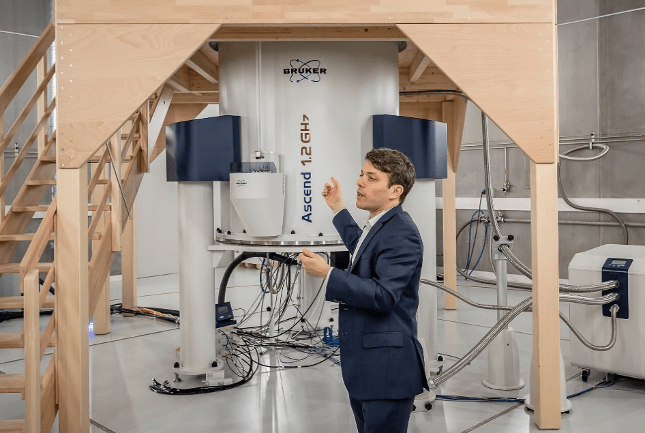

Notre Directeur Recherche et développement Jérémy Pallas, a partagé notre vision et nos savoir-faire en termes de traitement sur les nanotechnologies, l’intelligence artificielle et l’importance d’adopter les nouvelles technologies pour rester compétitif sur le marché mondial.

Nous sommes honorés d’avoir été invités par BFM Business à présenter notre entreprise, notre expertise et nos projets. Cela témoigne de la reconnaissance de notre travail et de notre détermination à repousser les limites de l’innovation.

Nous tenons à remercier chaleureusement toute l’équipe de BFM Business pour cette opportunité exceptionnelle, ainsi que nos collaborateurs, partenaires et clients qui ont contribué à notre réussite.

Si vous avez manqué notre passage sur BFM Business, nous vous invitons à le regarder en ligne (Jérémy Pallas (Themis) : Themis est un fabricant de solutions de filtration – 08/07 (bfmtv.com)) et à découvrir comment Antara Groupe façonne l’avenir de la filtration des fluides.

Nous sommes ravis de partager cette expérience avec vous et de continuer à innover. Restez à l’écoute pour de nouvelles mises à jour passionnantes ! www.antara-groupe.com

Jérémy Pallas (Themis) : Themis est un fabricant de solutions de filtration – 08/07 (bfmtv.com)

#AntaraGroupe #Innovation #BFMBusiness #TransformationNumérique #Leadership #Succès #FocusPME #Nanotechnologie #ESR #Huilehydraulique #Lubrification #Biocarburant #Varnishhydraulicoil #Diesel

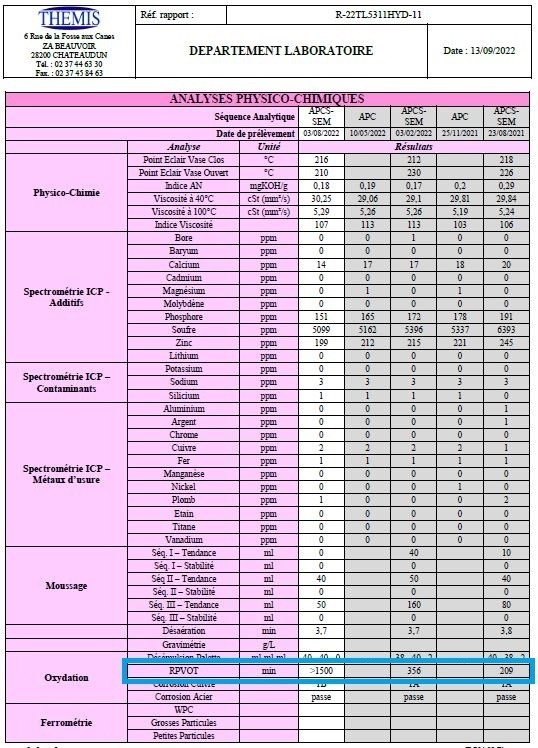

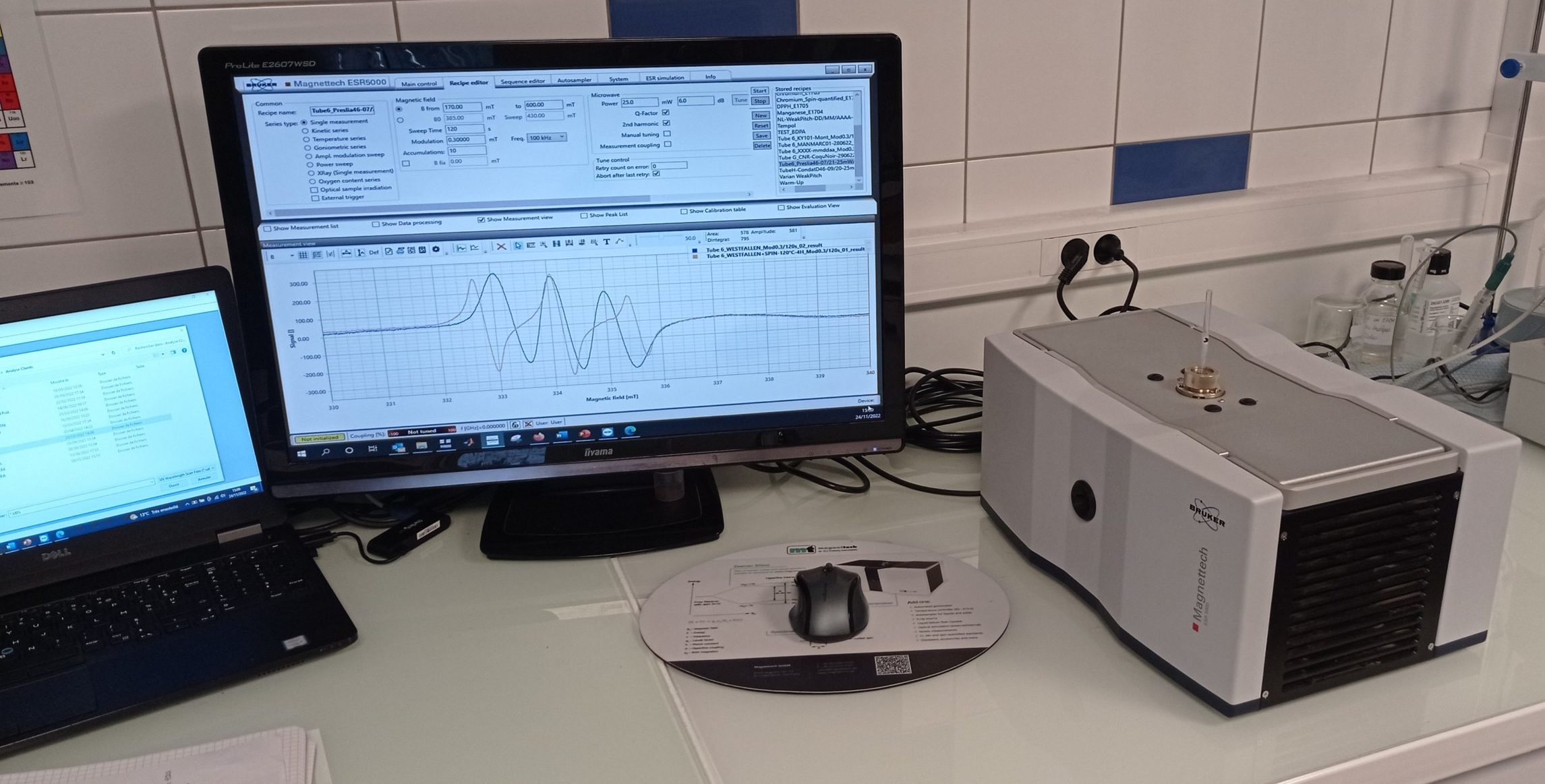

As part of the OilDoc show, one of the world's leading events for fluid management, monitoring and maintenance, we were privileged to contribute our expertise at a conference which highlighted technological advances in the field of fluids and what the very near future holds in terms of management. Among the topics discussed, we particularly highlighted the importance of RPE (Retention Prevention Efficiency) in industry.

EPR represents the best approach to preventing oxidation residues and anticipating varnish formation, meeting your growing fluid management requirements. Our conference highlighted the latest technological advances and innovative solutions that will enable us to achieve an even higher level of finesse.

We are proud to contribute to the industry with solutions that optimize fluid performance and ensure efficient management. Our commitment to innovation and excellence continues to propel us into the future.

We'd like to extend our warmest thanks to everyone who attended our conference, and we remain committed to meeting the challenges of the fluids industry by offering you ever more advanced solutions.

#OilDoc2023 #FluidManagement #EPR #Oipurification #Innovation #Filtration #Varnishhydraulicoil #Residusdoxydation

During its participation at the African Mining Indaba 2023, ANTARA GROUPE presented its innovative solutions in industrial filtration and fluid purification for the mining industry in Africa.

As a leading supplier in the sector, ANTARA GROUPE has demonstrated its expertise and commitment to developing and manufacturing tailor-made solutions to meet the specific challenges of the mining industry in Africa.

ANTARA GROUPE's team of experts took center stage at African Mining Indaba 2023, where they presented their advanced industrial filtration technologies. Their innovative solutions aroused keen interest among mining industry professionals attending the event.

Filtration technologies optimize mining production processes by removing contaminants from the fluids used. These solutions not only help to improve operational efficiency and reduce maintenance costs, but also ensure the preventive maintenance of mining operations.

ANTARA GROUPE's participation in the African Mining Indaba was an ideal opportunity to strengthen existing partnerships and establish new contacts within the African mining industry. Their recognized expertise was once again showcased.

ANTARA GROUPE continues to push the boundaries of innovation in industrial filtration and fluid purification, contributing to the growth of the mining industry in Africa. Their expertise and tailored solutions make them a partner of choice for companies seeking optimal performance and sustainable practices. #MiningIndaba #MiningAfrica #ANTARA groupe #Mining #Innovation #Hydraulicoil #Lubrication #Biofuel #Varnish #Diesel #Filtrationinmiluminier

Subscribe to our channel: ANTARA GROUPE - YouTube

Link linkedin page: ANTARA GROUPE : Presentation | LinkedIn

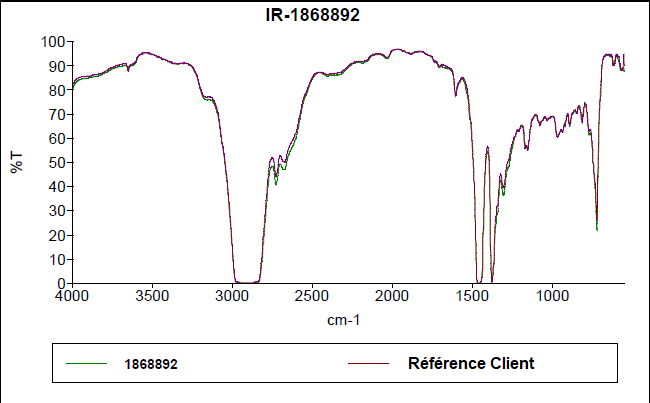

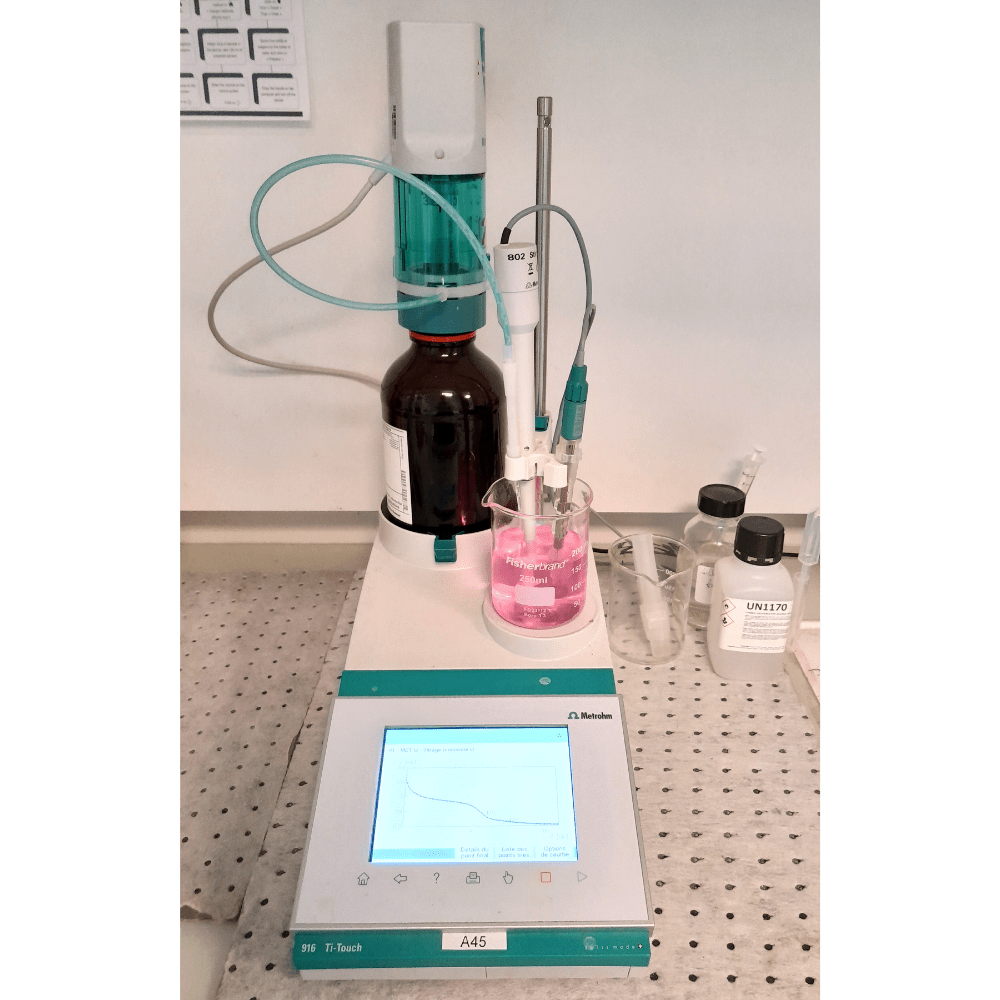

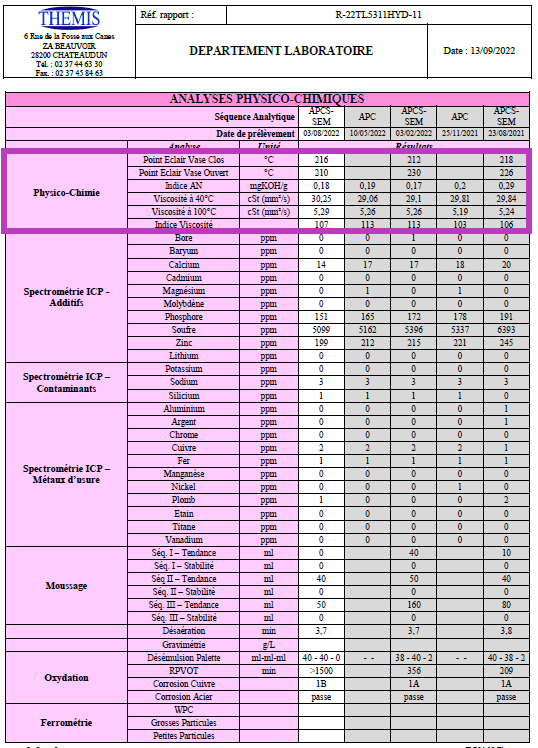

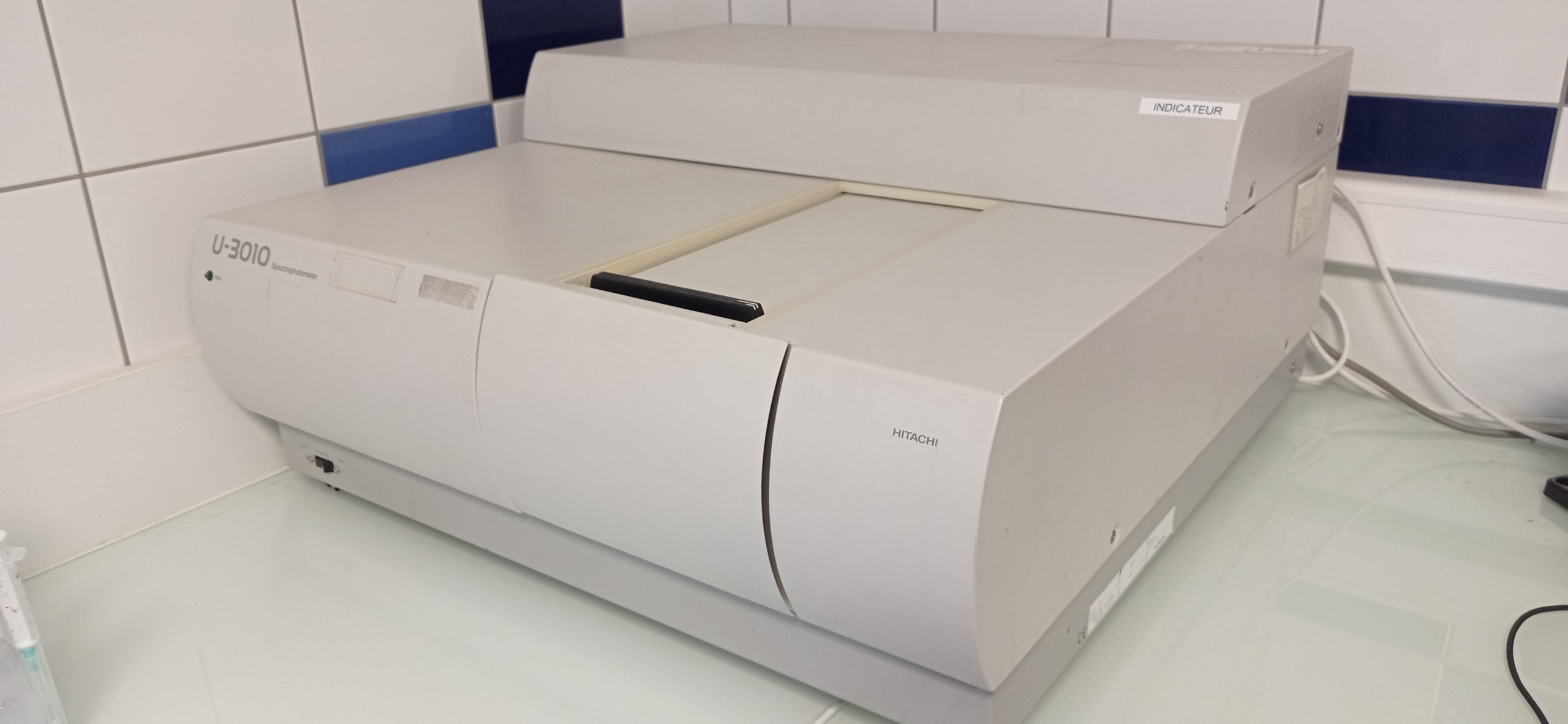

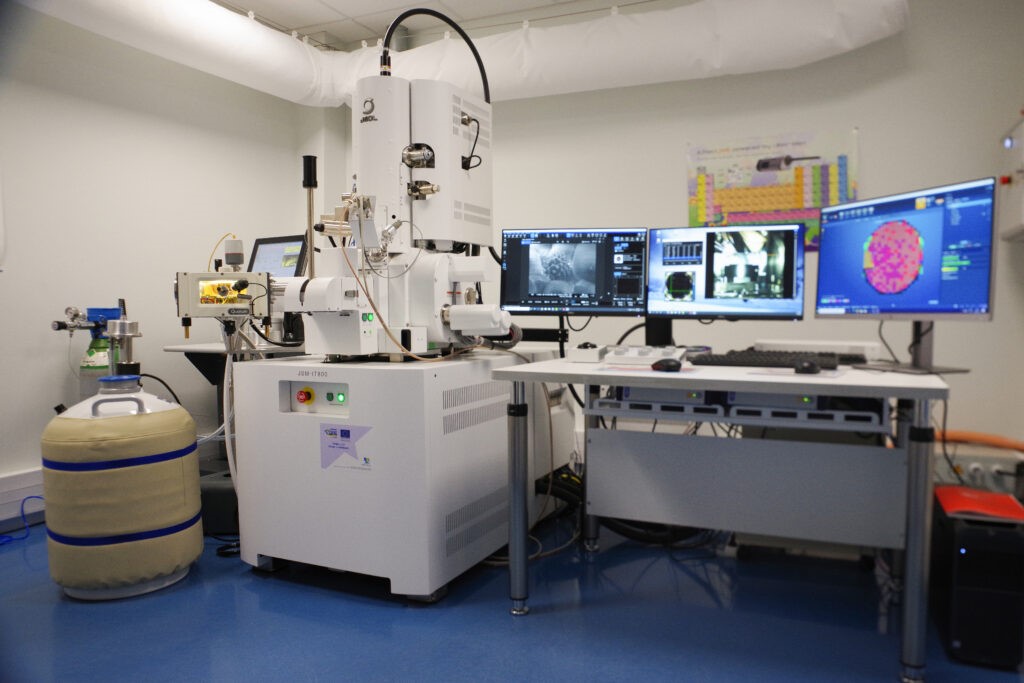

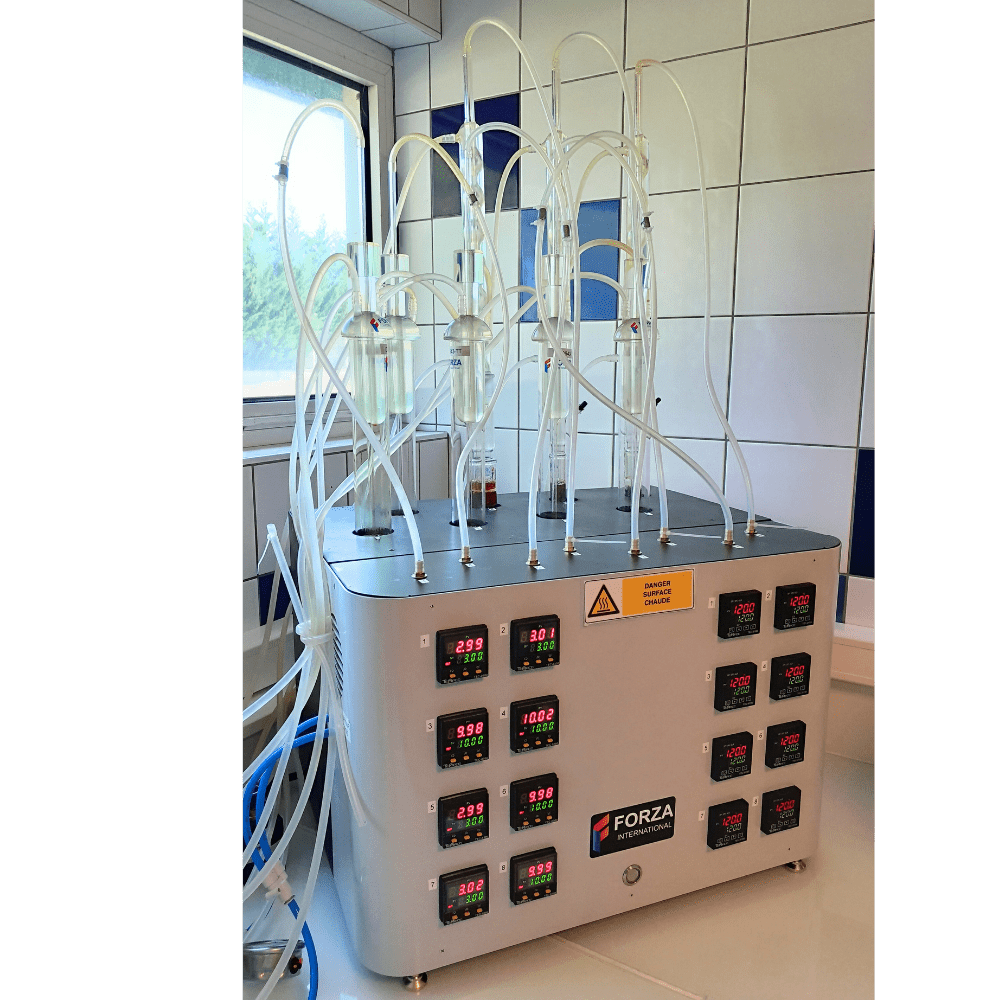

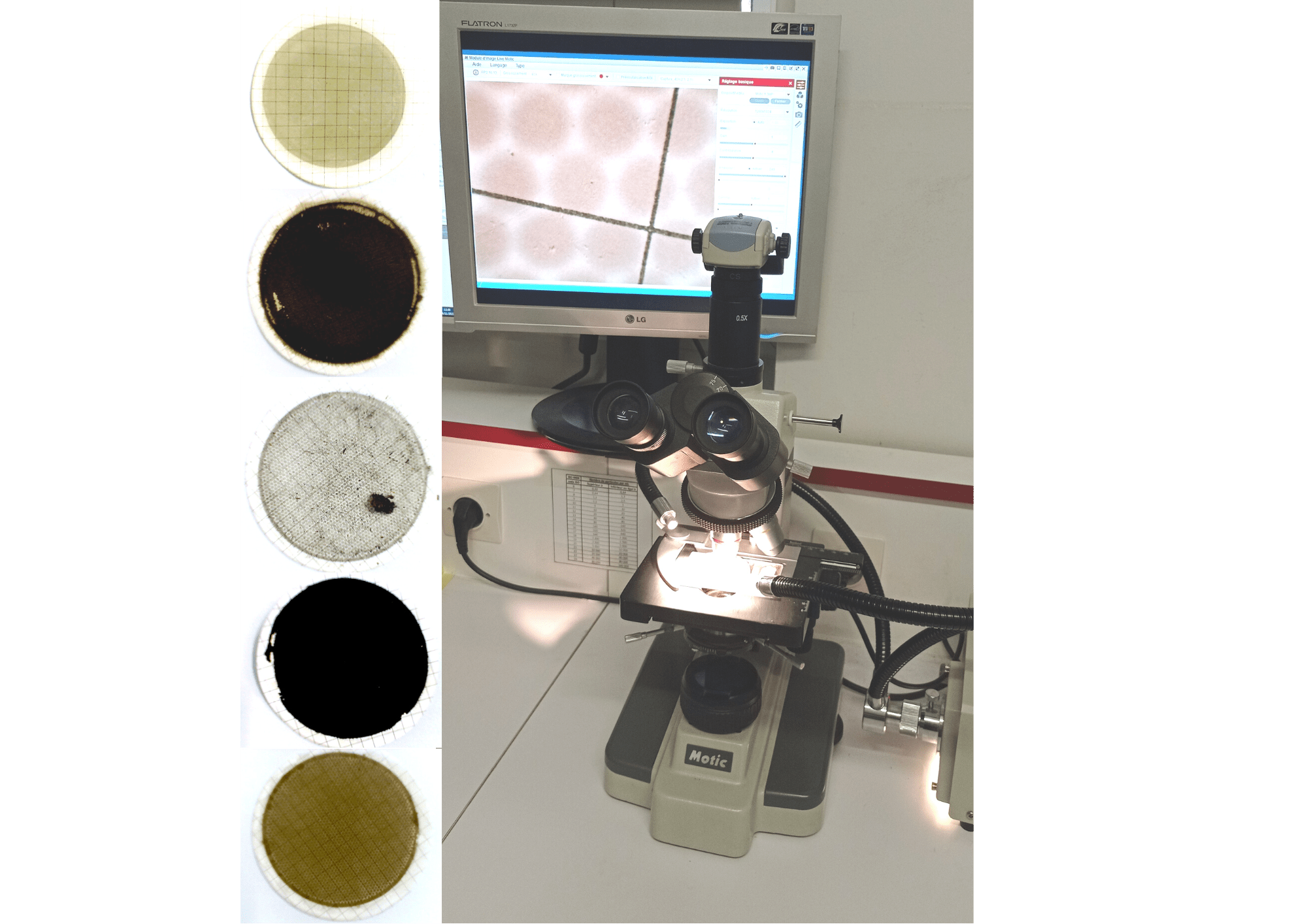

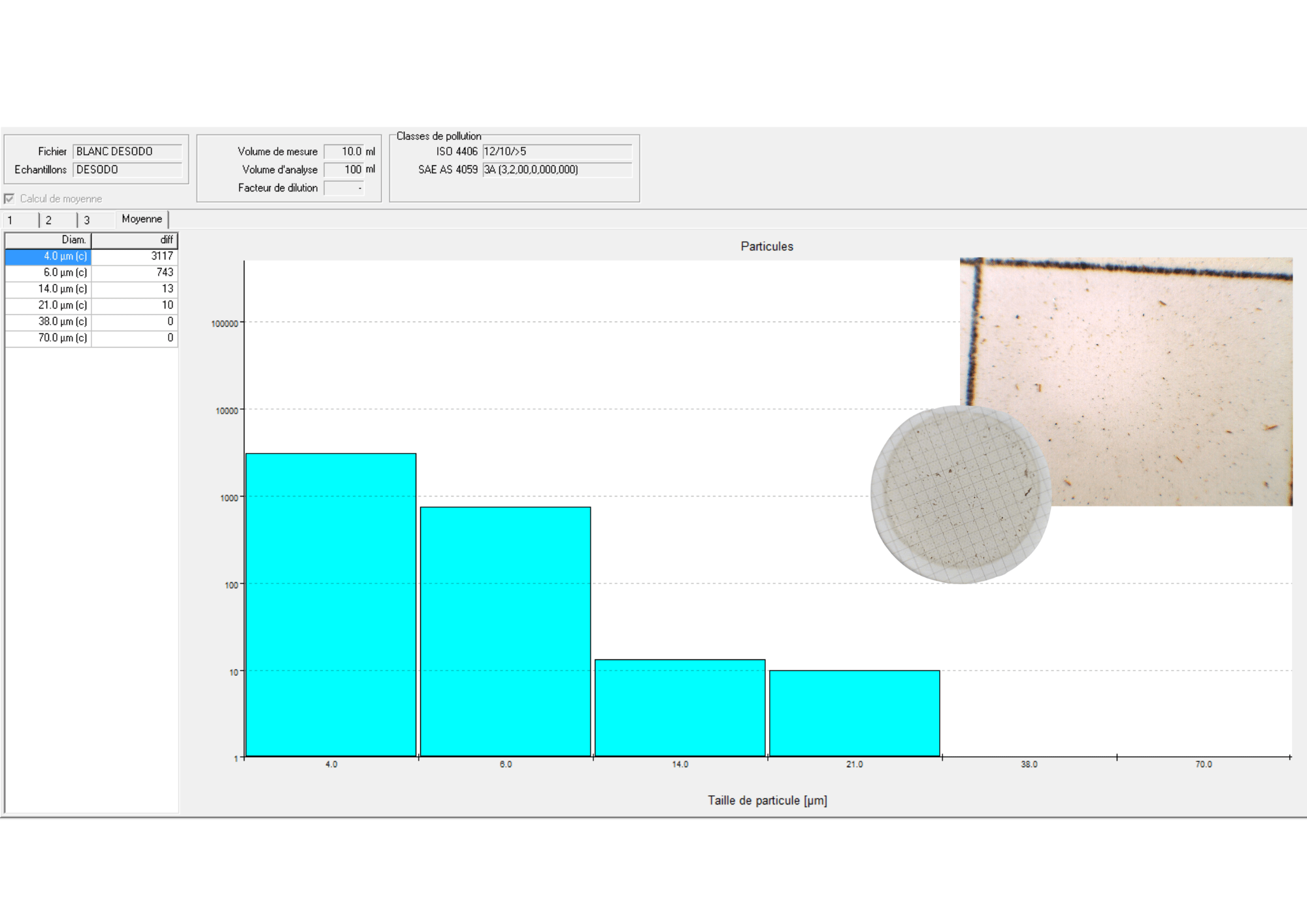

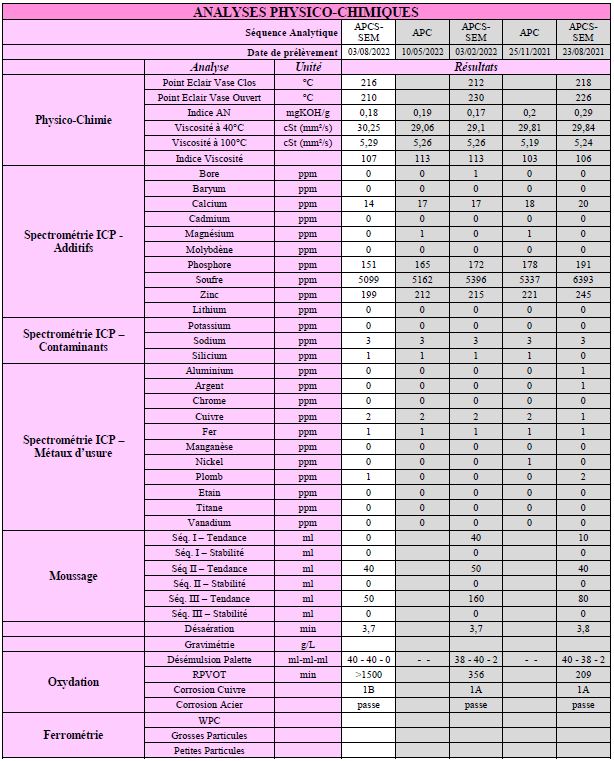

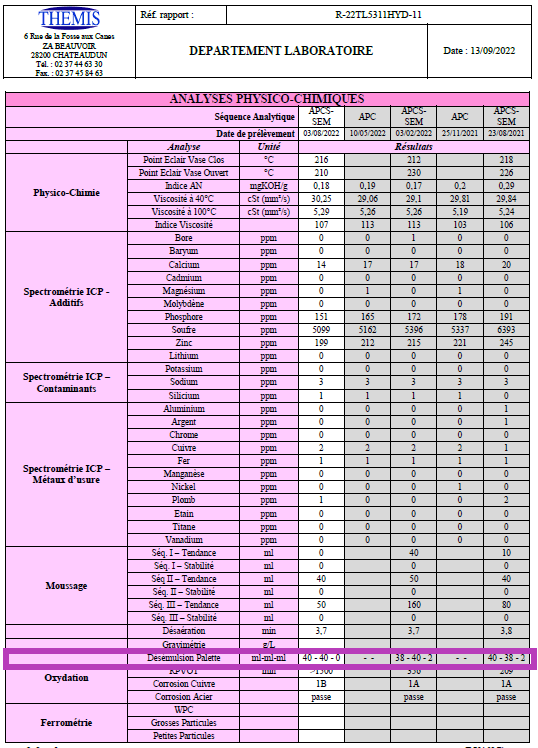

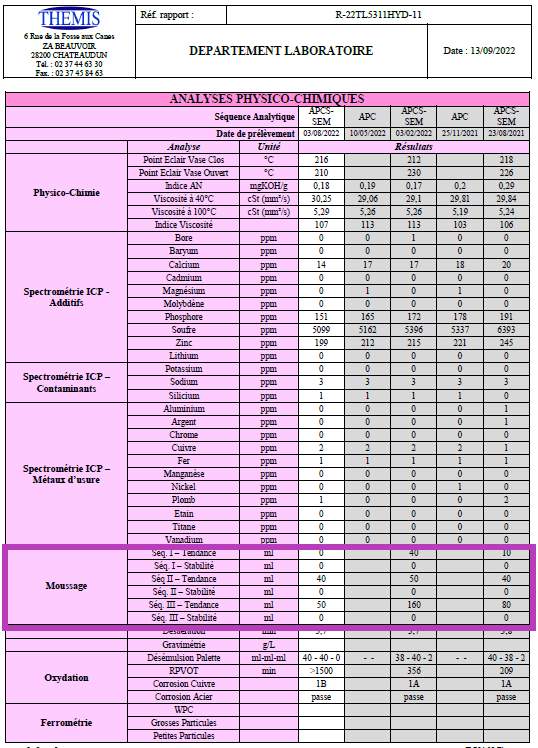

In support of your technical choices, your developments, your optimizations, not to mention our full range of laboratory analysis, ANTARA GROUPE invests heavily in its research and analysis offer, which is why we have doubled our laboratory space and equipped ourselves with the latest tools to go even further in meeting the challenges.