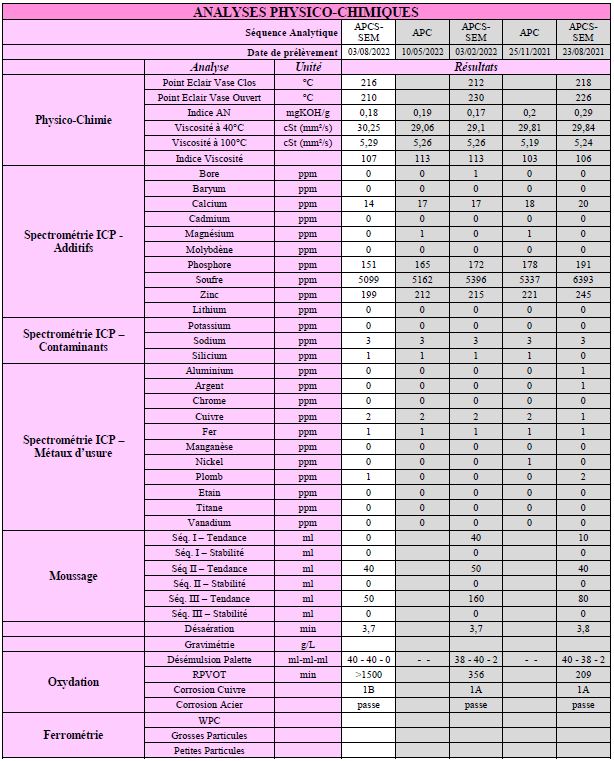

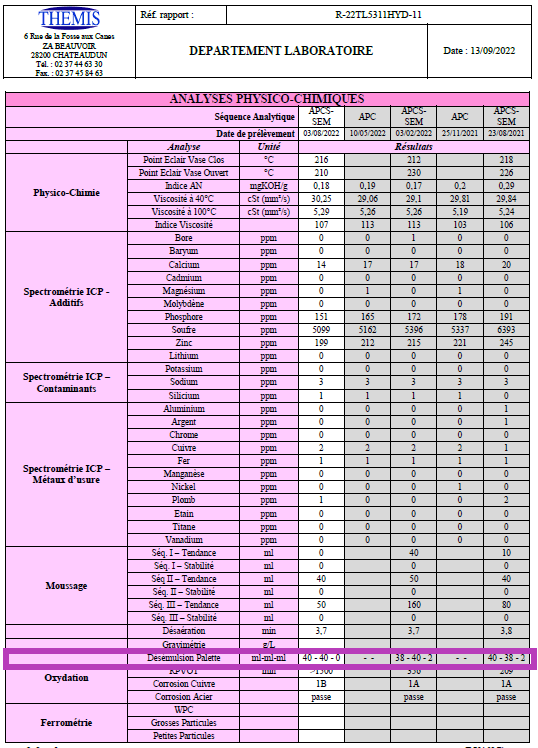

Addressing Industrial Challenges

In industries like fuel, mining, manufacturing, and aerospace, hydraulic systems are essential-but face a major challenge: oil contamination. Pollutants like water, gases, particles, and oxidation by-products degrade hydraulic fluids, leading to higher maintenance costs, equipment damage, and downtime.

Traditional methods (filters, centrifuges, coalescers) provide only partial solutions and require frequent servicing.

To address this, Antara Groupe developed ARTHEMIS-a cutting-edge oil purification system that integrates four advanced treatments into one, offering a more complete and efficient solution.

A new way to dehydrate and treat oil for optimal cleanliness and performance at low temperature (38°c).

100% designed and manufactured in France, ARTHEMIS ensures continuous purification with unmatched efficiency, significantly extending oil life, enhancing machine reliability, and reducing environmental impact.

Breakthrough Innovations: Vacuum Dehydration & Emulsion Breaking

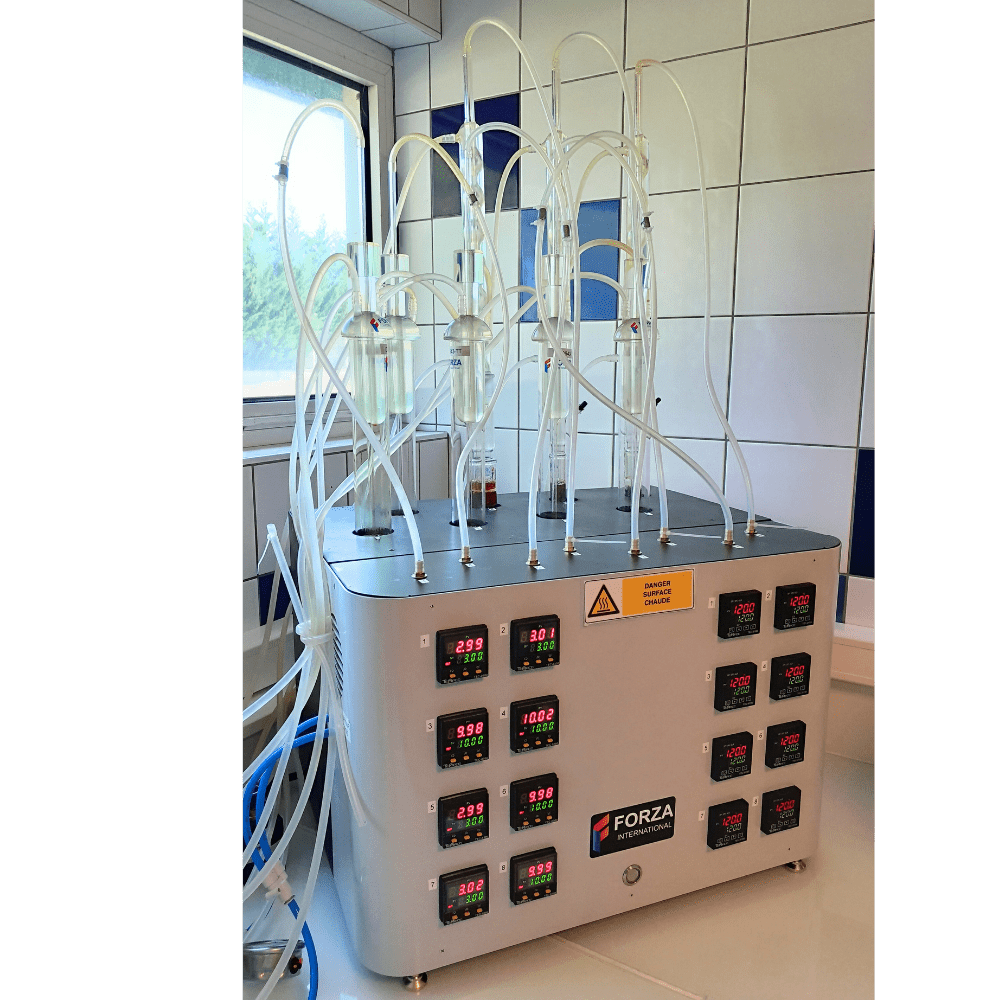

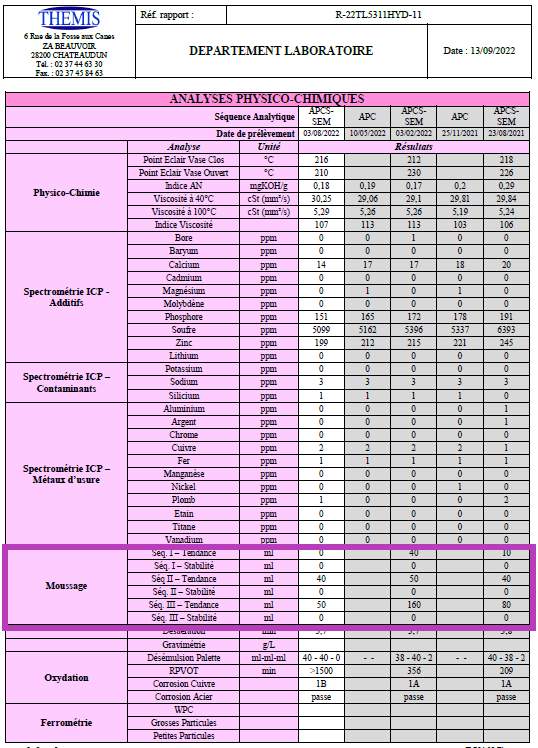

NAUTILUS (Vacuum Dehydration) Removes free and dissolved water without altering additives or viscosity.

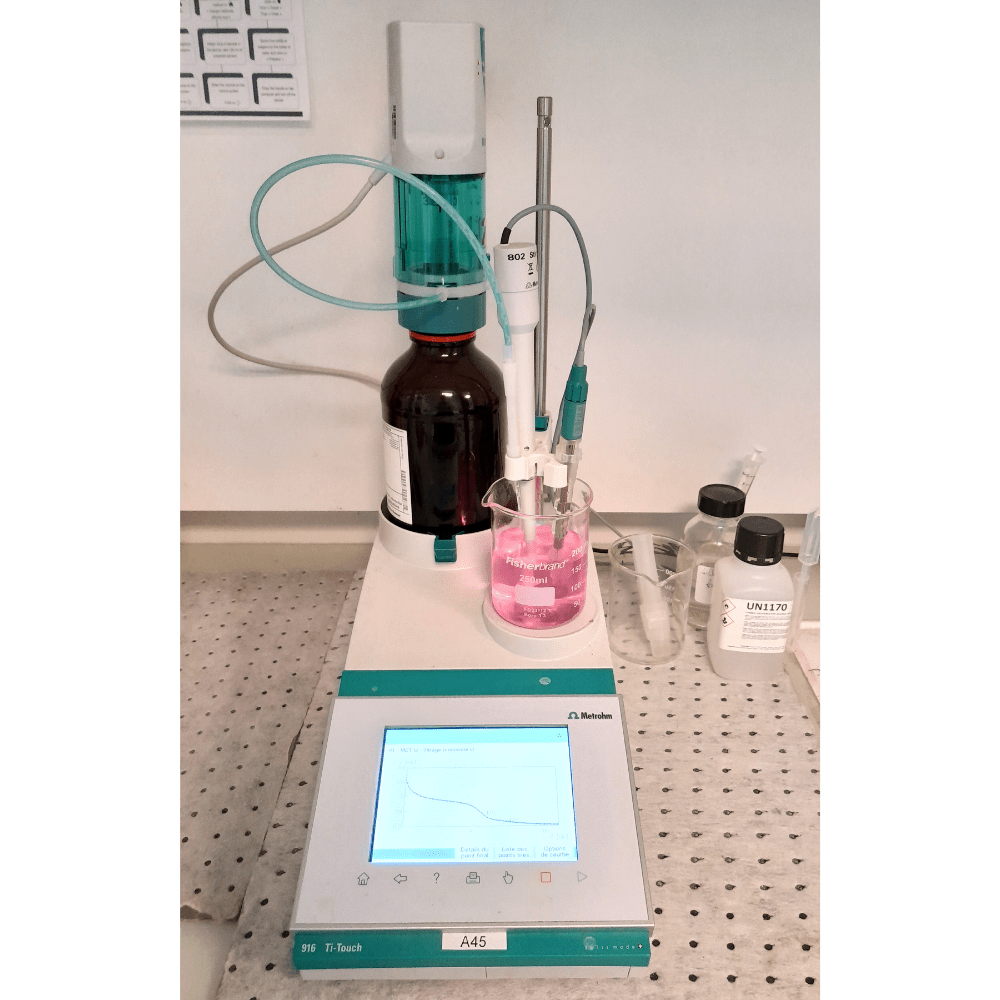

Water is one of the most harmful contaminants in hydraulic and lubrication systems. Unlike conventional methods, ARTHEMIS uses vacuum dehydration to remove both free and dissolved water. By operating under vacuum, it lowers the boiling point of water, extracting moisture at low temperatures while preserving oil additives and viscosity.

Emulsion Breaking Eliminates stable emulsions that traditional methods cannot handle.

Water contamination often leads to the formation of stable emulsions, which traditional filtration methods fail to break. ARTHEMIS is designed to separate even the strongest emulsions, ensuring oil is fully dehydrated and restored to optimal performance levels. This process prevents

corrosion, cavitation, and wear, extending the lifespan of hydraulic components.

A System Designed to Maximize Oil and Equipment Lifespan

✔ No need for draining – Oils are continuously purified and recycled

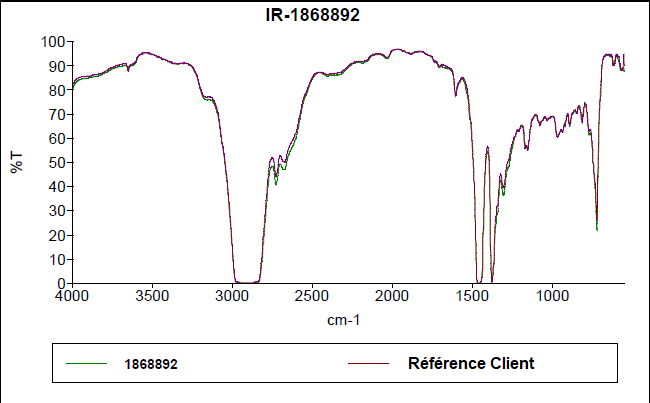

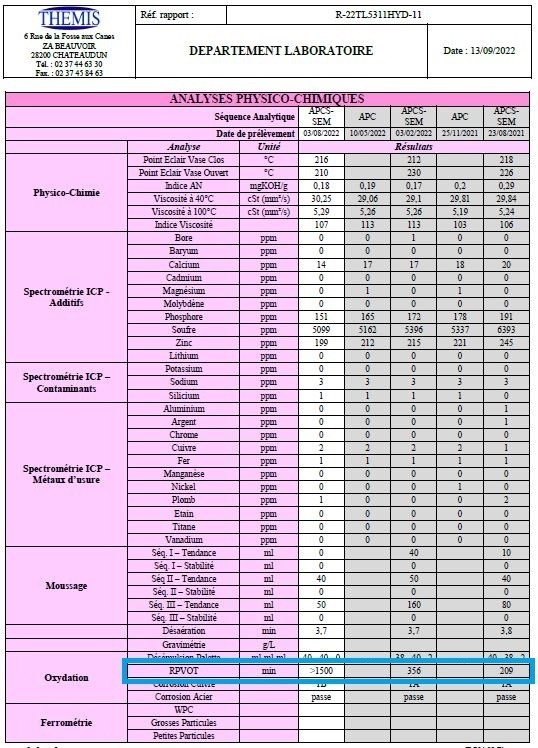

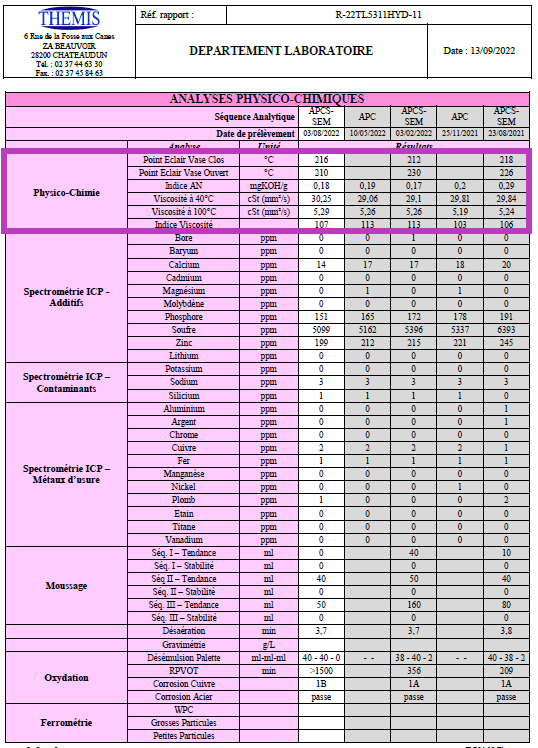

✔ Preserves additives and oil’s physico-chemical properties

✔ Removes emulsions and varnish to prevent long-term damage.

✔ Reduces operational costs and extends machinery lifespan

A Cost-Effective & Eco-Friendly Solution

By addressing all contamination types in a single continuous process, ARTHEMIS reduces maintenance needs, minimizes oil replacement frequency, and lowers waste production, contributing to sustainable industrial practices.

« With ARTHEMIS, Antara Groupe sets a new benchmark in hydraulic oil purification, delivering a powerful, efficient, and long-term solution to oil contamination challenges. »

ARTHEMIS: A Unique System with 4 Treatments in 1

1 system = 4 simultaneous treatments

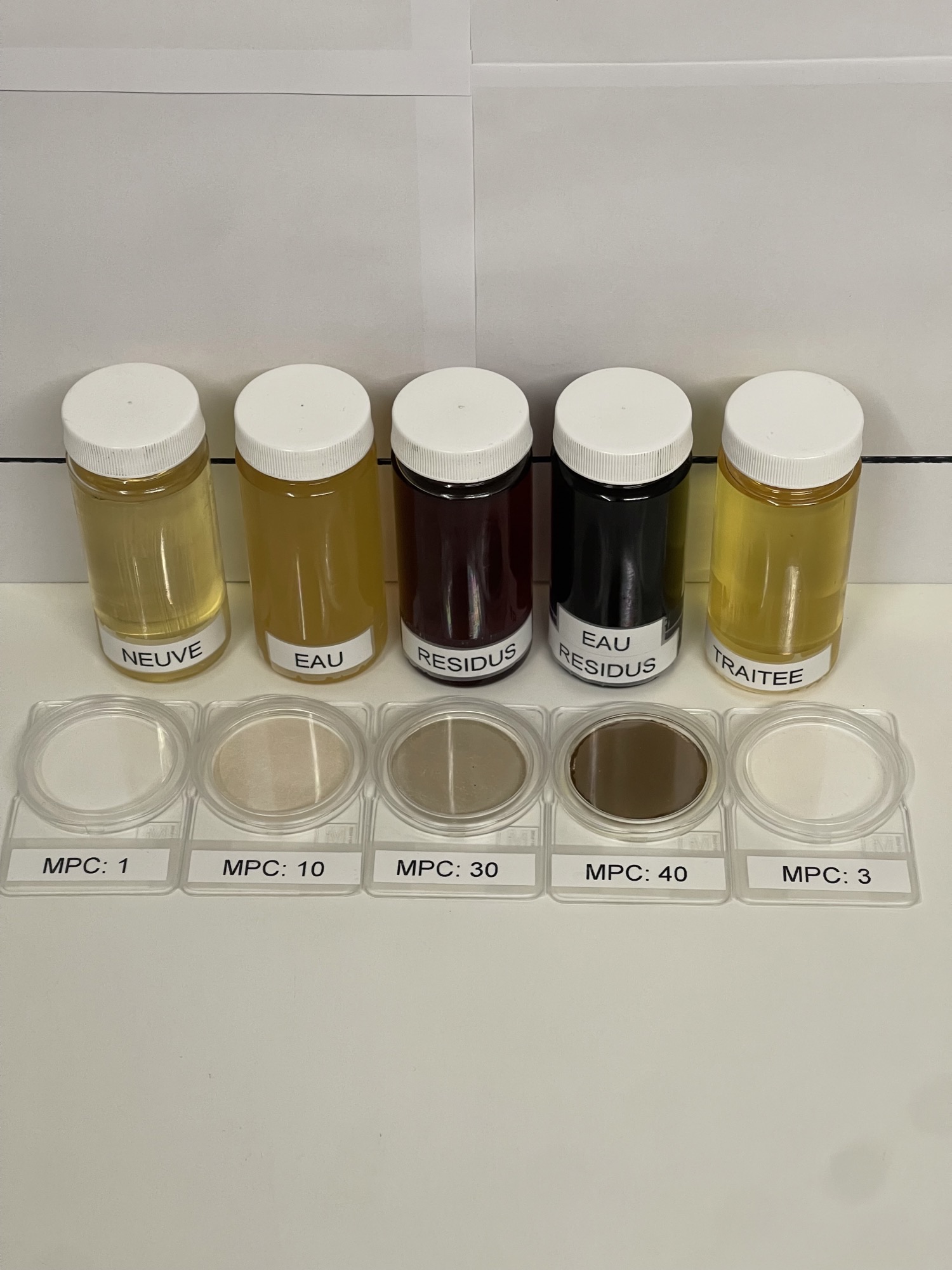

- Eliminates 100% of free water and up to 96% of dissolved water (from 50,000 ppm to 10 ppm in a few hours at low temperature )

- Breaks strong emulsions and corrects foaming issues

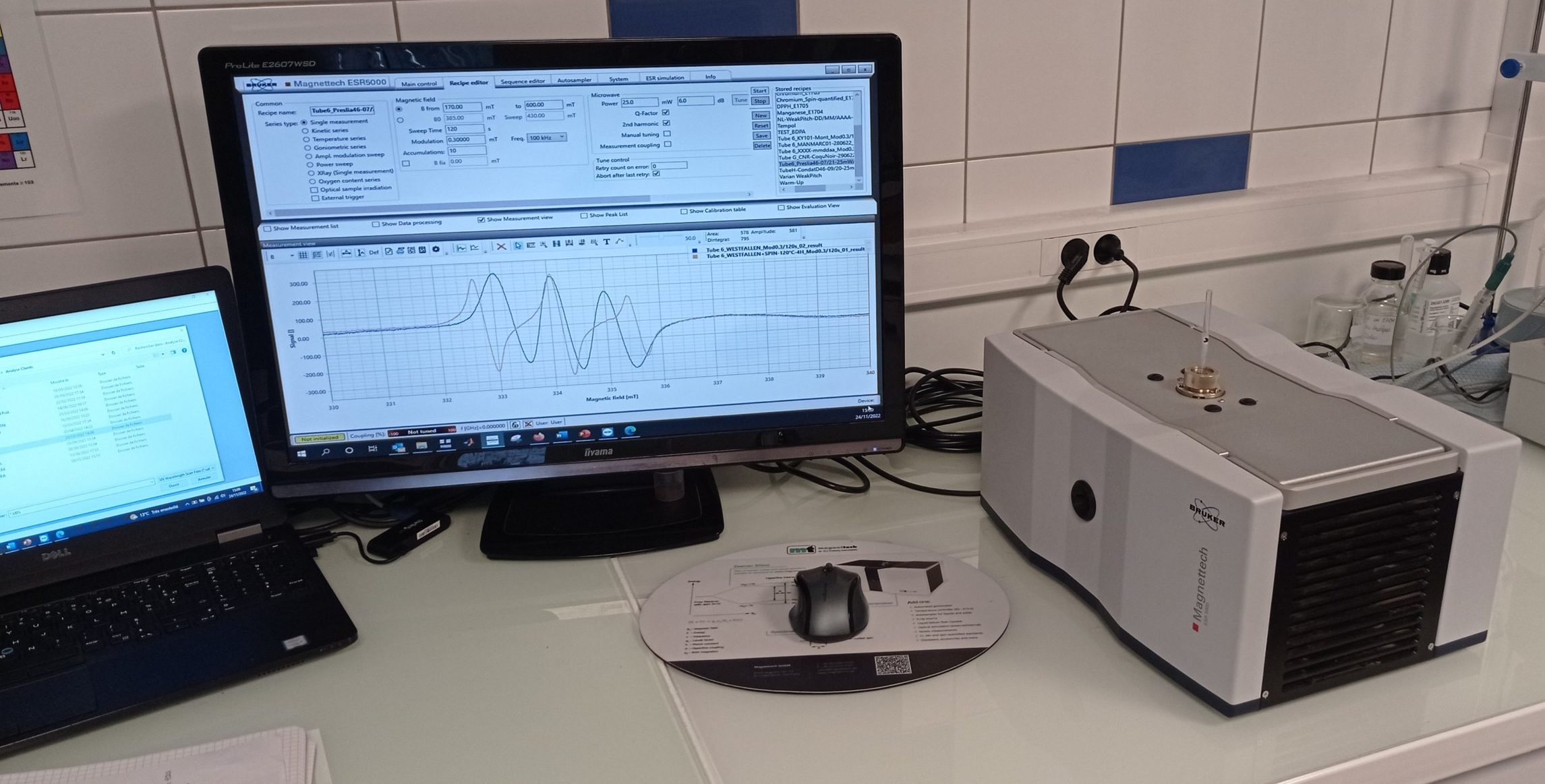

- Reduces oxidation effects (MPC from 50 to 10, acidity from 2 to 0.07)

- Extracts 100% of free gases and 95% of dissolved gases

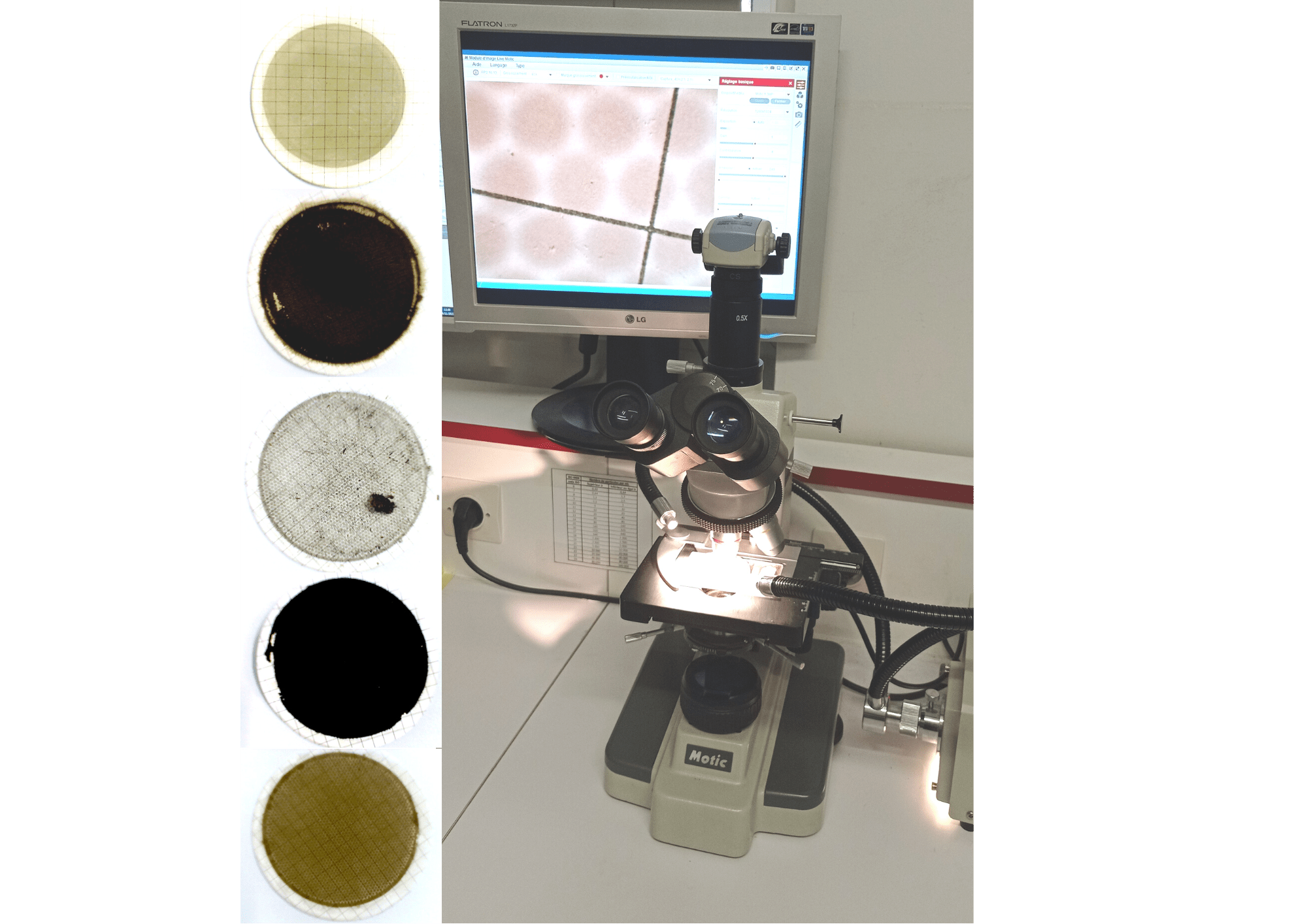

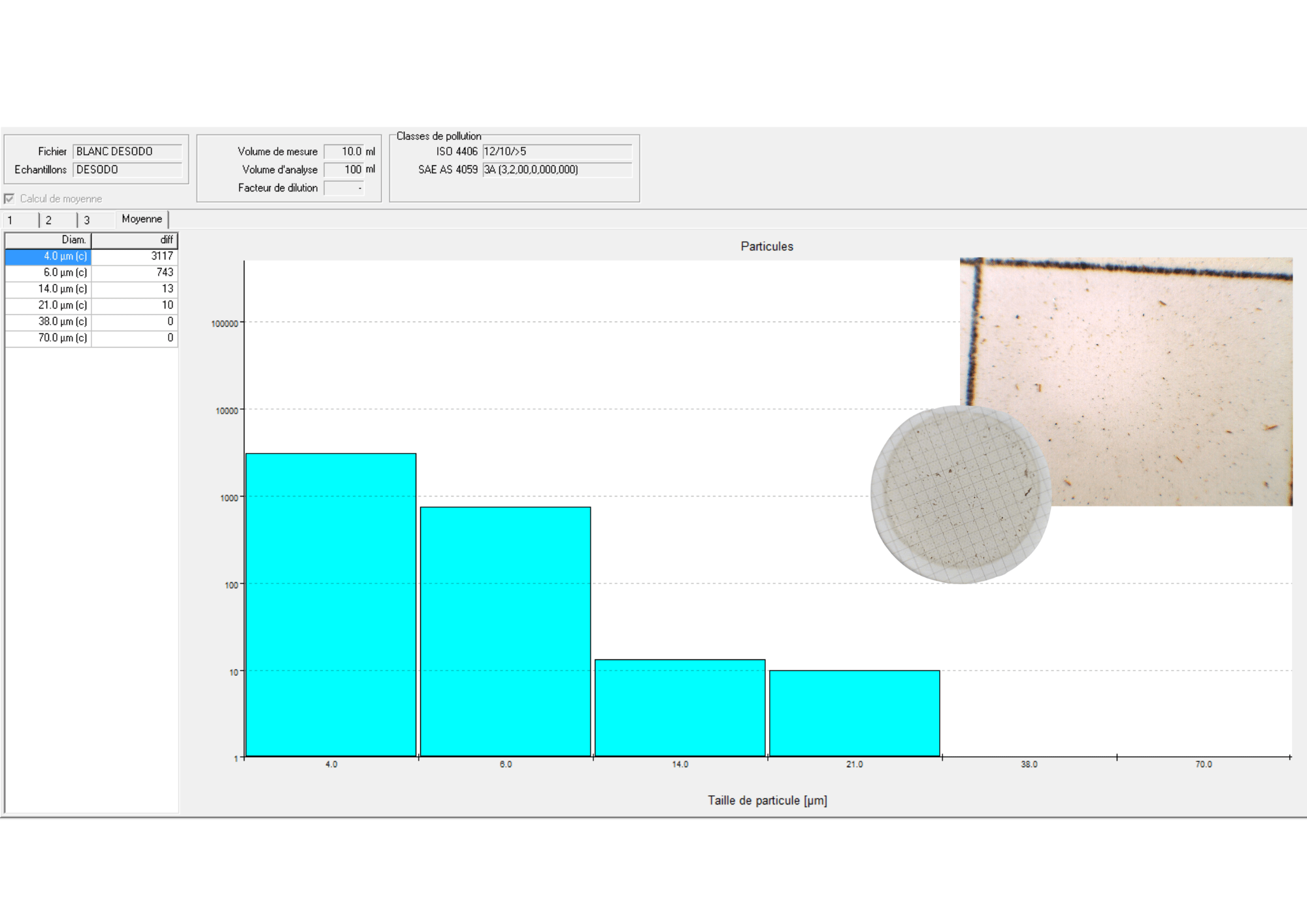

- Filters down to ISO 4406 = 10/11/09, ensuring superior oil cleanliness

- Uses advanced molecular filtration and Extension Mode

to eliminate varnish and oxidation residues