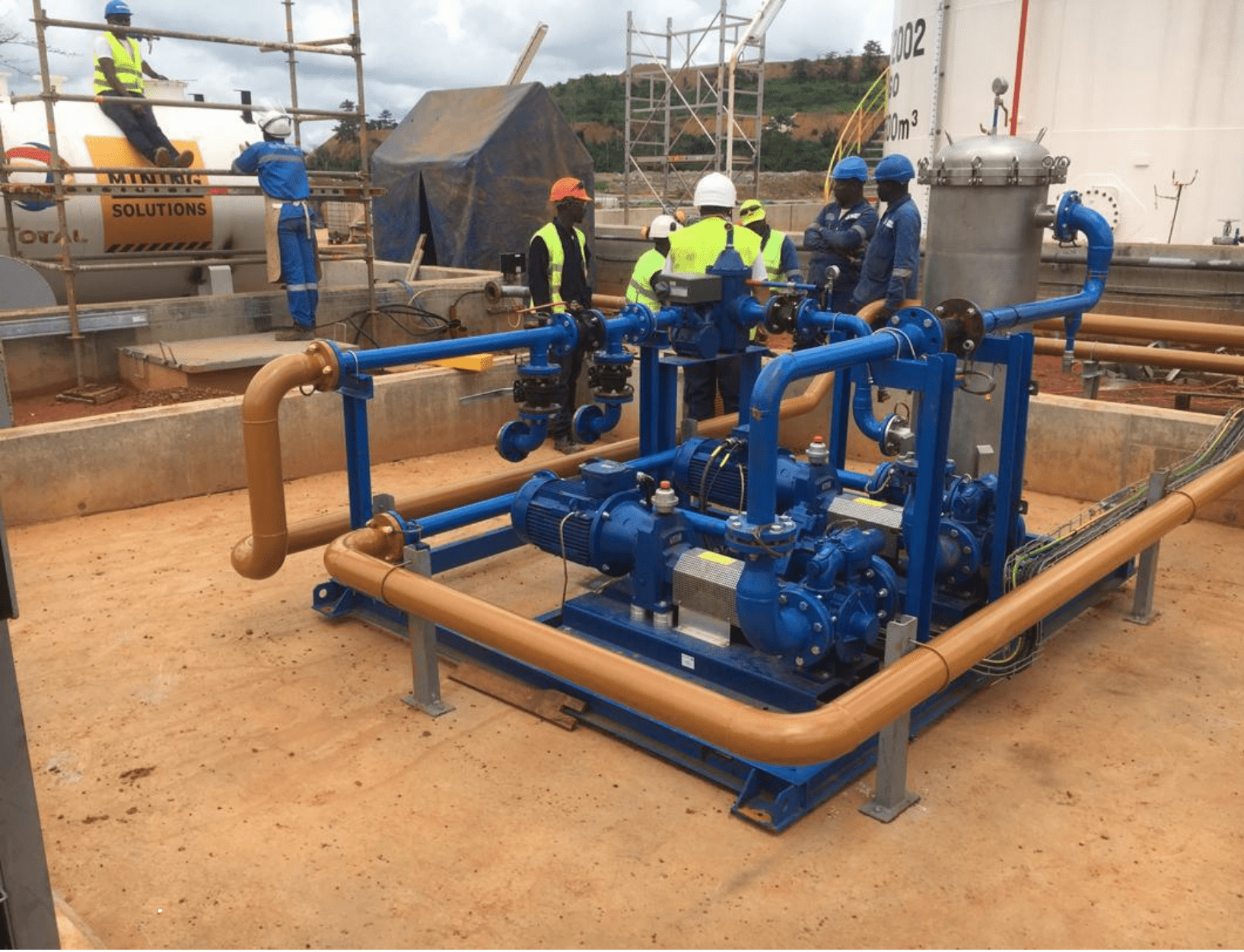

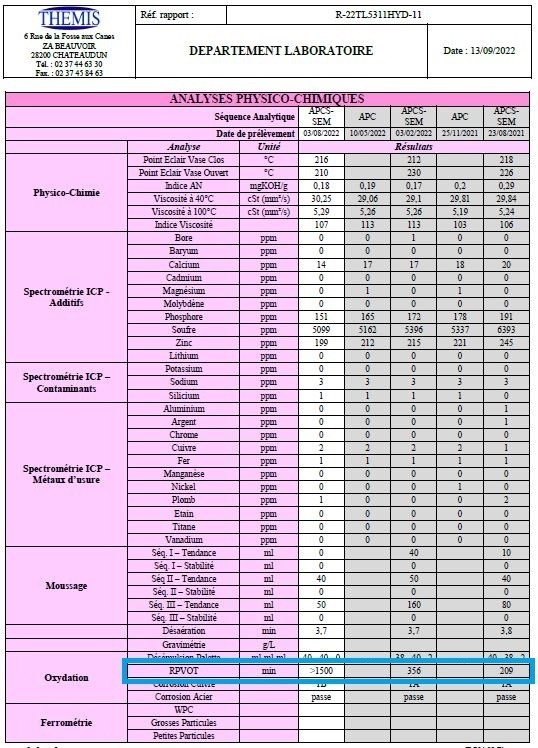

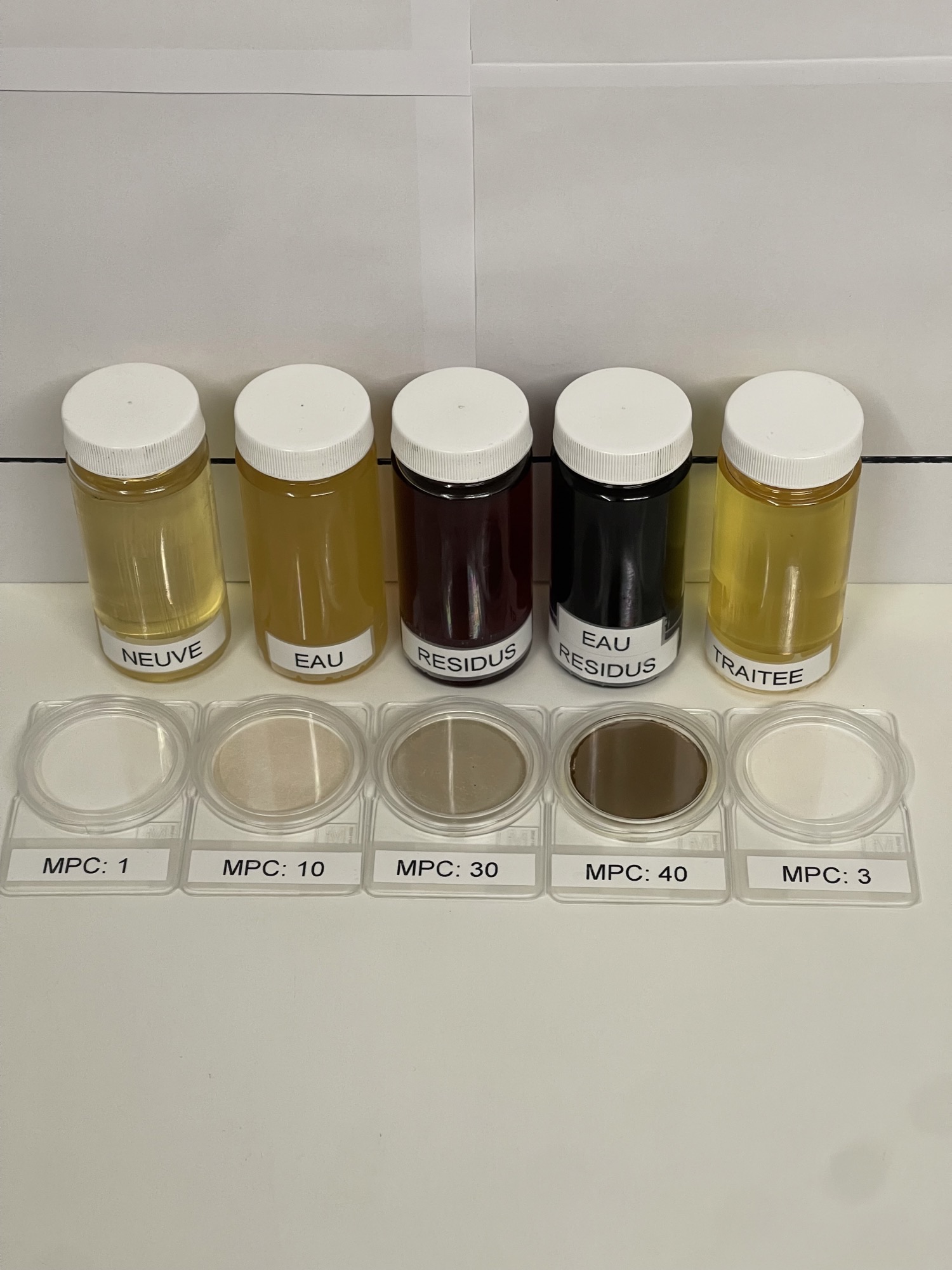

Case study – Underground tanks

- Posted in ANTARA GROUPE, International, New technologies

Antara Groupe joins ICML as an Affiliate Member

- Posted in ANTARA GROUPE, International, New technologies

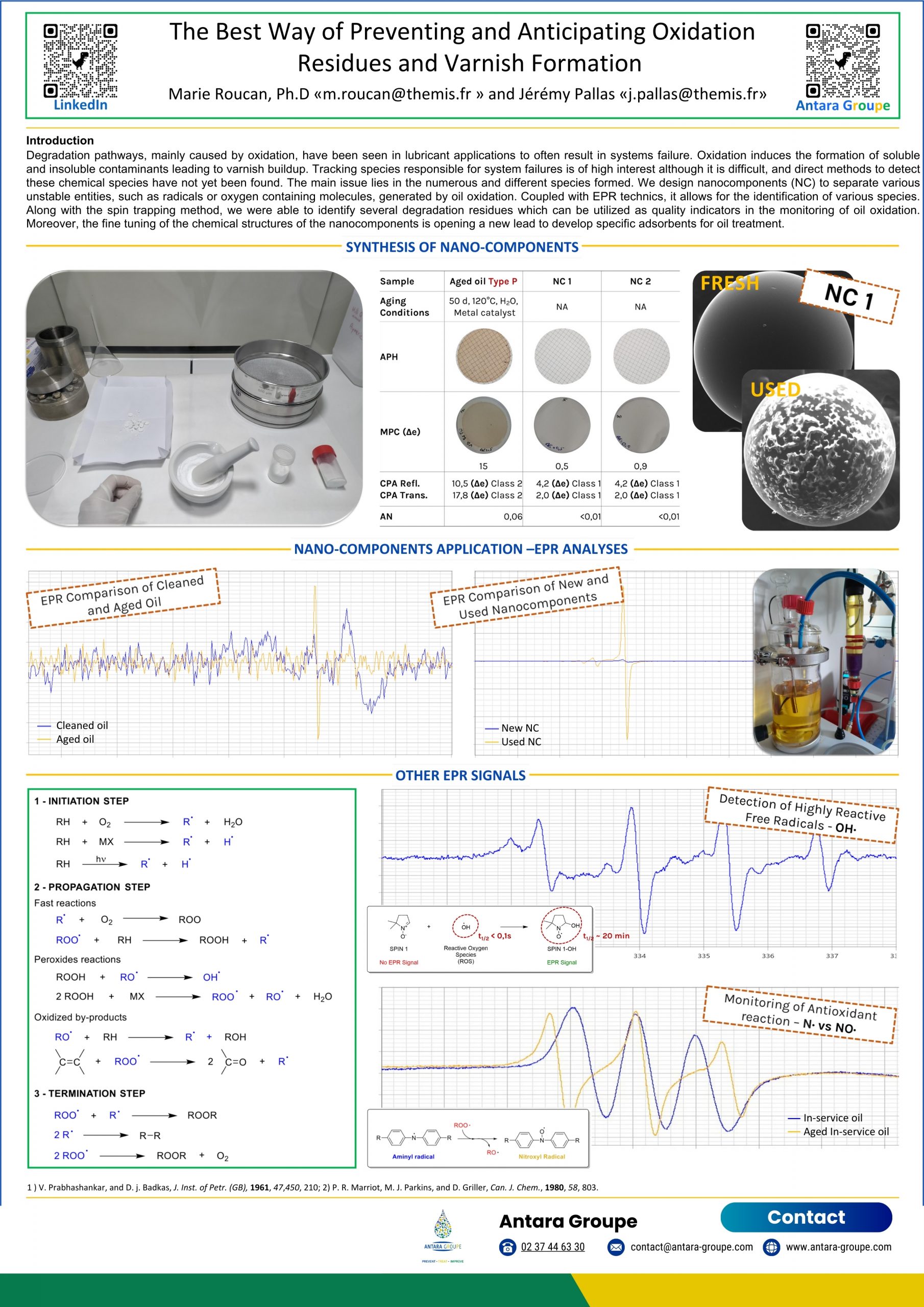

Antara Groupe at STLE 2025 – Anticipating and Preventing Oxidation & Varnish Build-Up

- Posted in ANTARA GROUPE, International, New technologies

ARTHEMIS: The Technological Innovation That Reinvents Hydraulic Oil Purification

- Posted in ANTARA GROUPE, International, New technologies

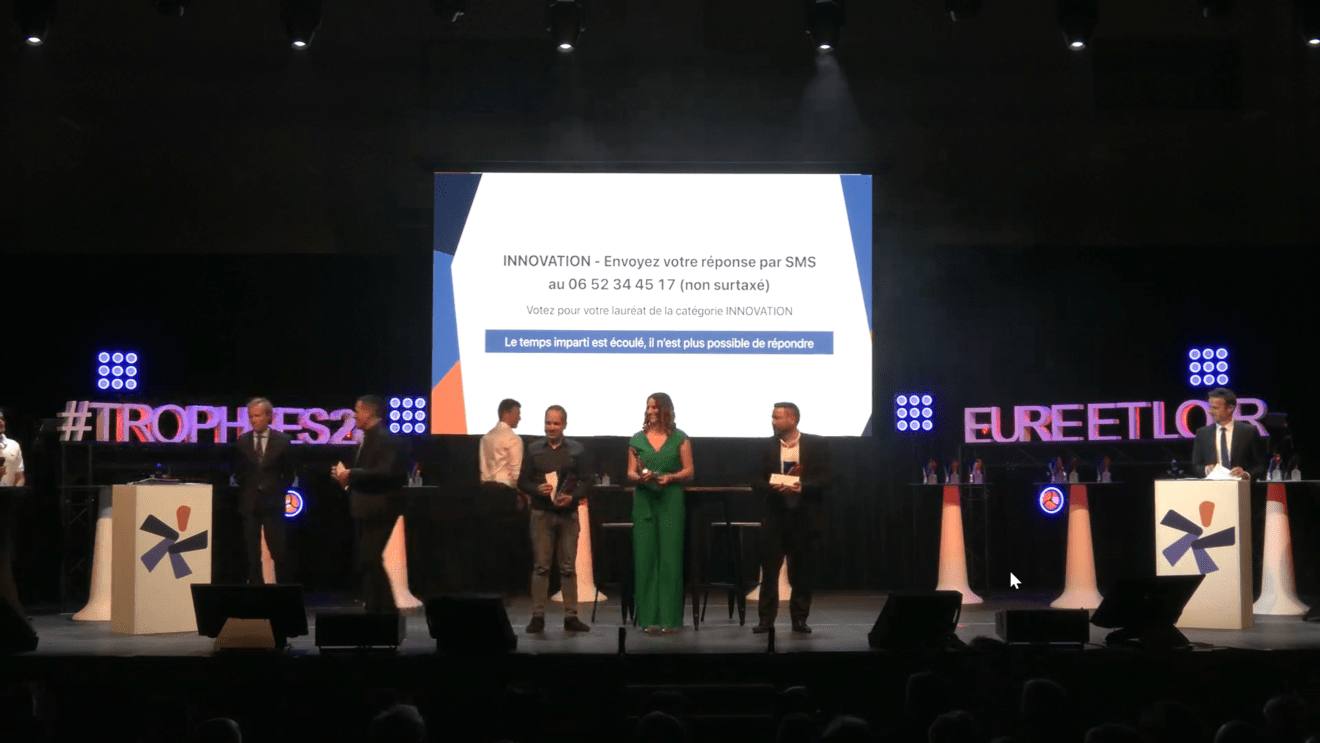

THEMIS Filtration: Winner of the 2024 Innovation Prize at the Trophées des Entreprises

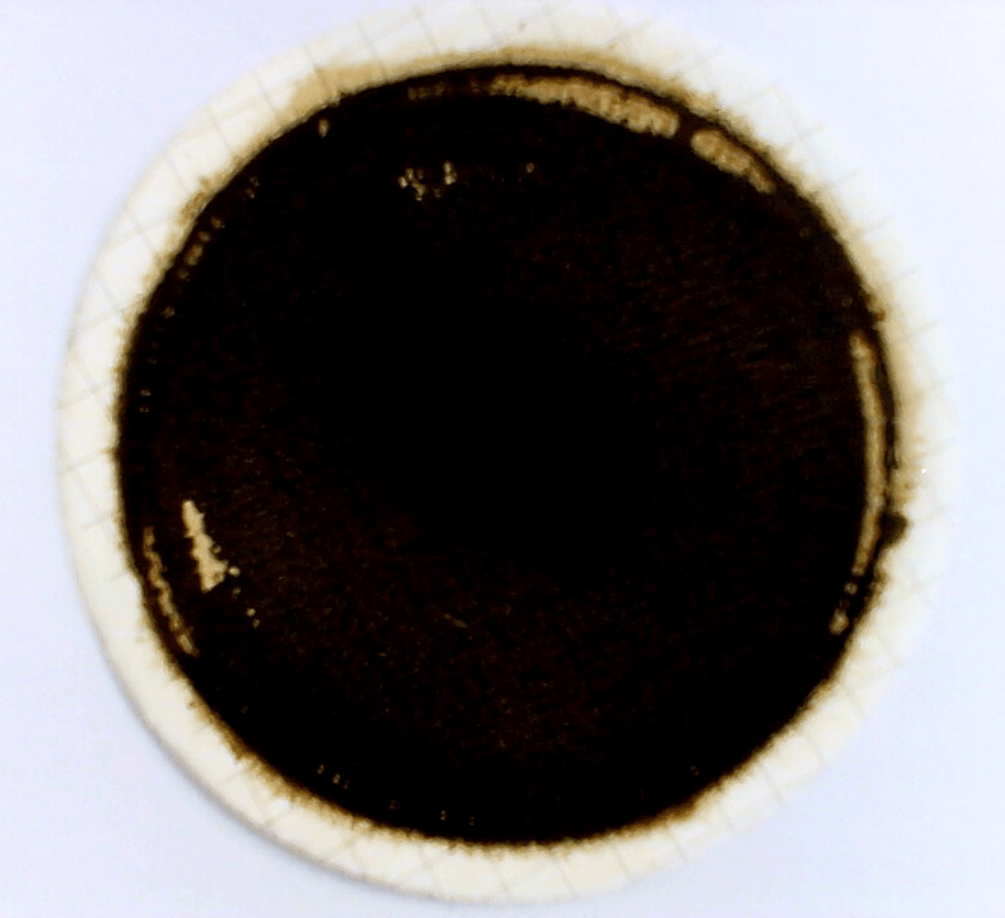

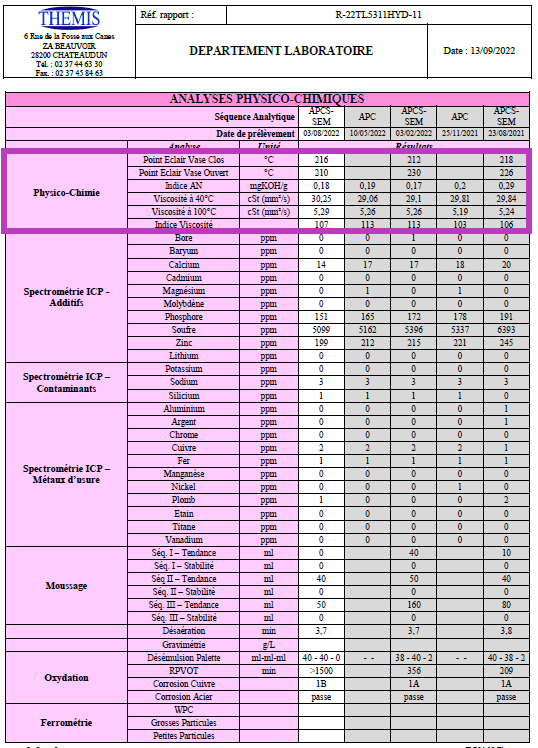

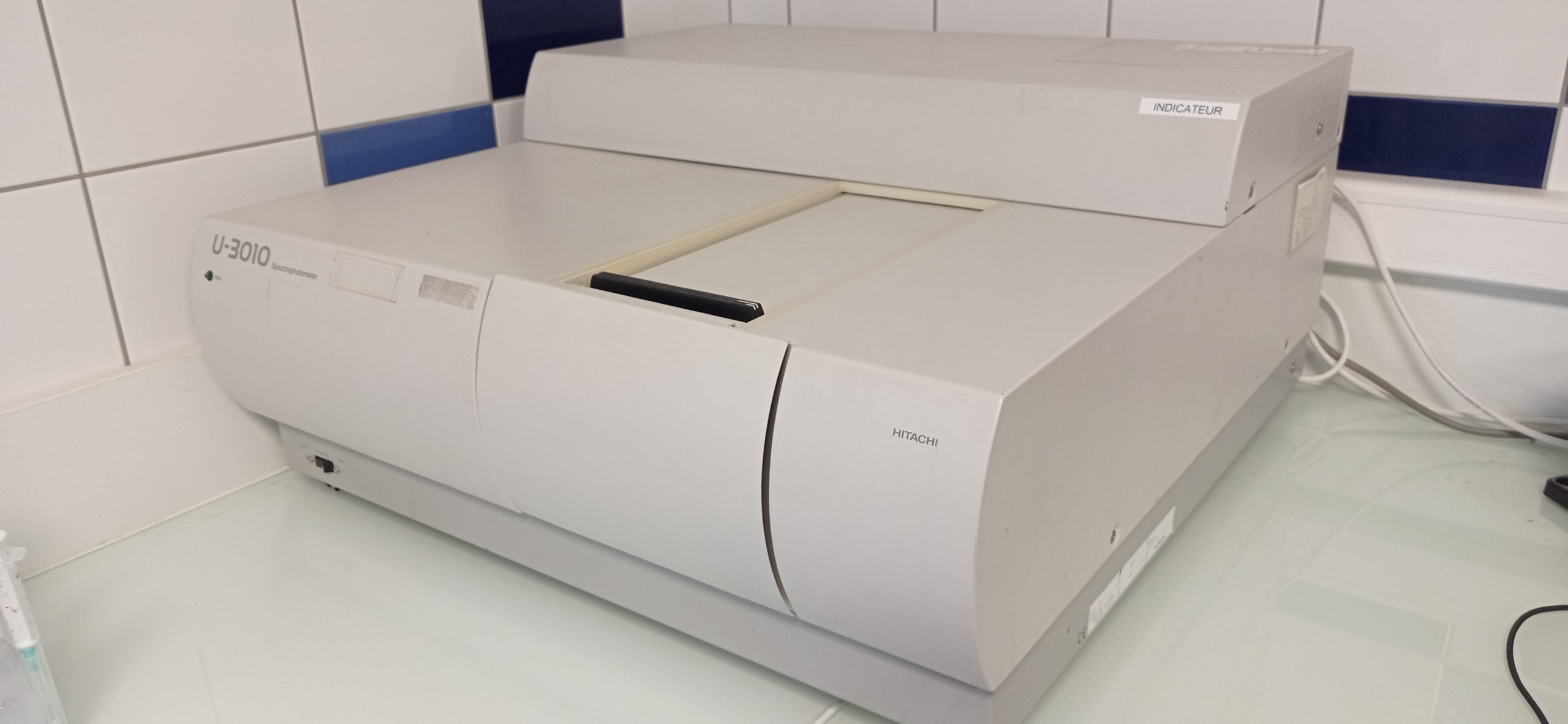

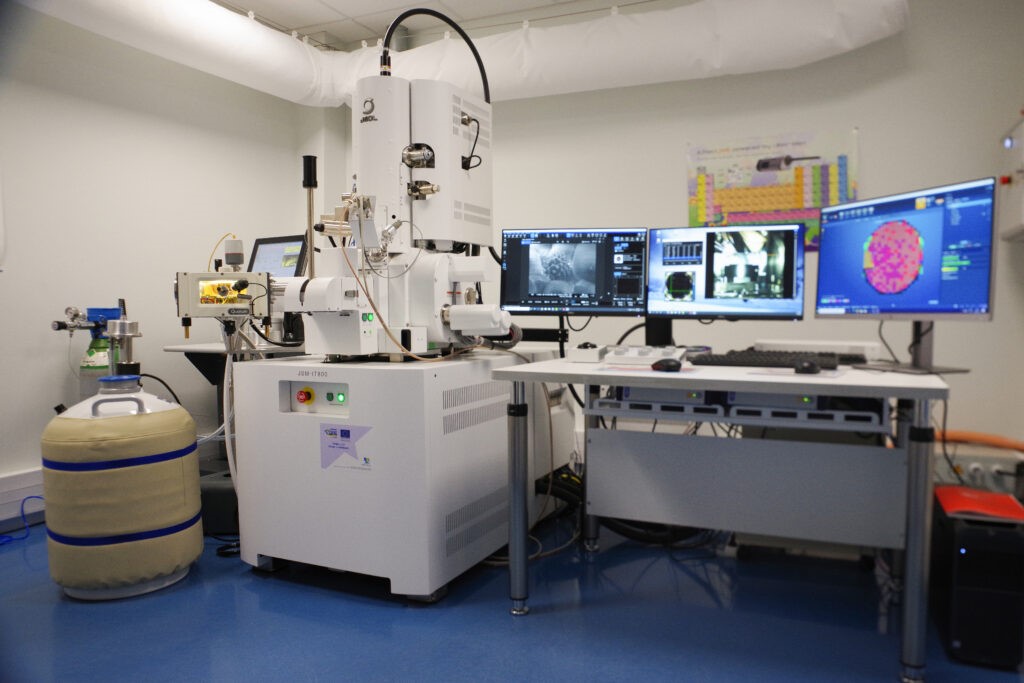

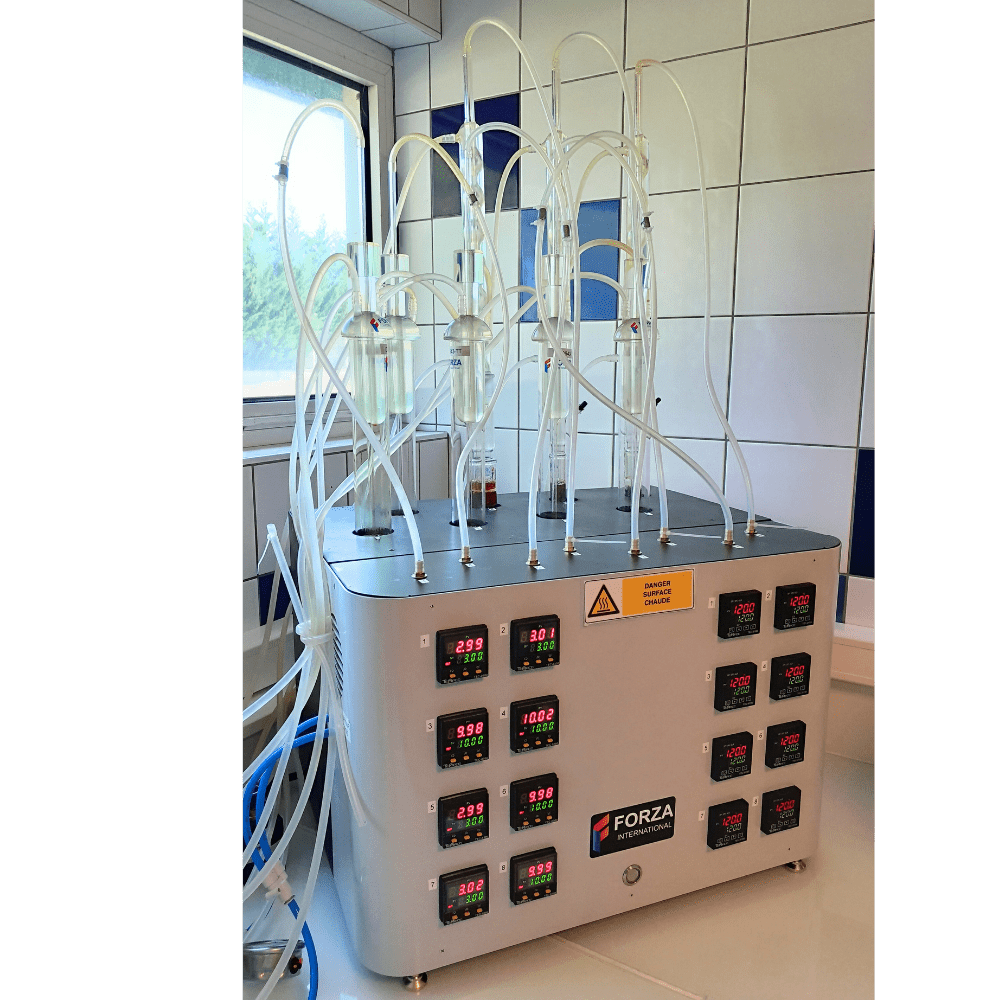

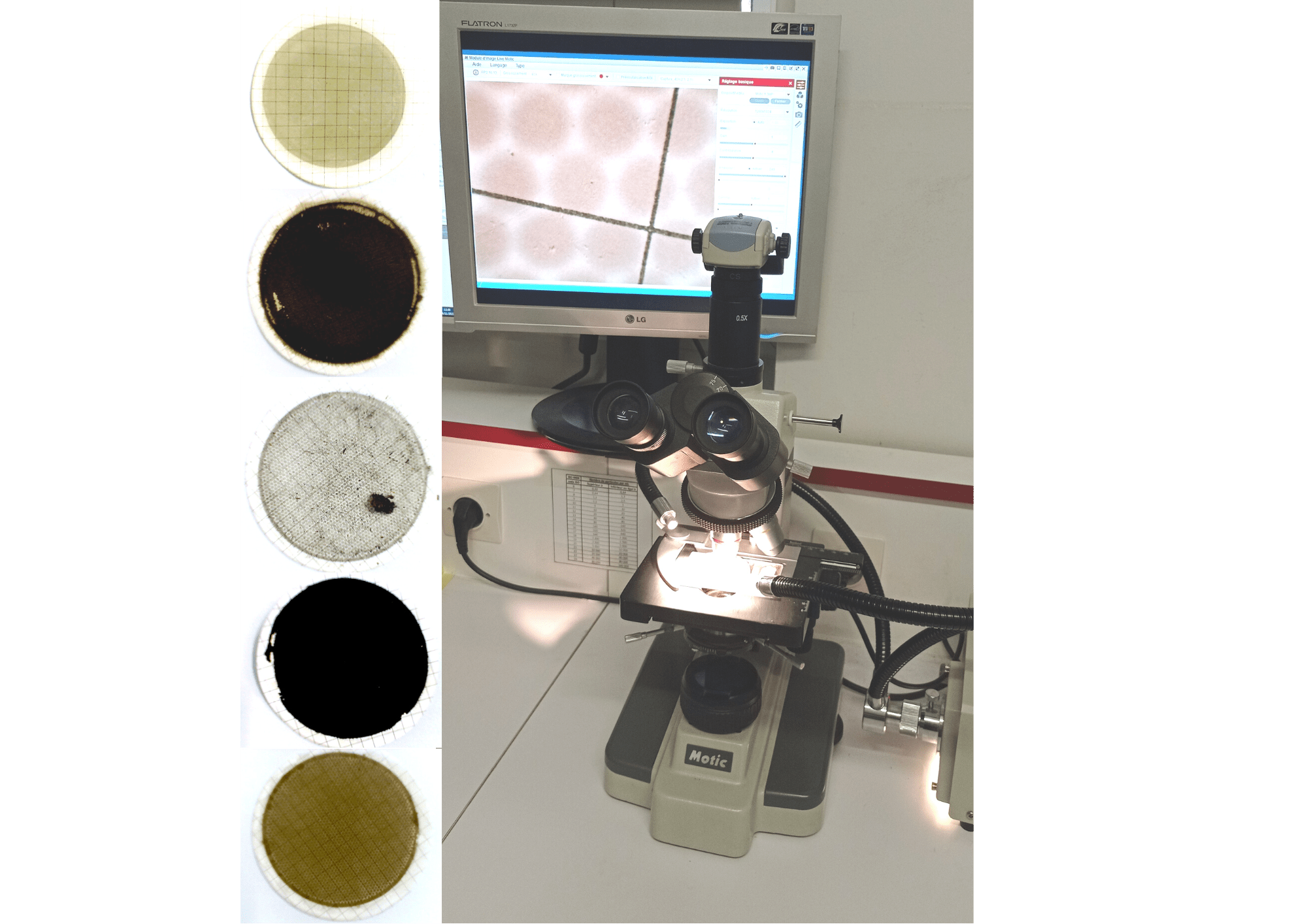

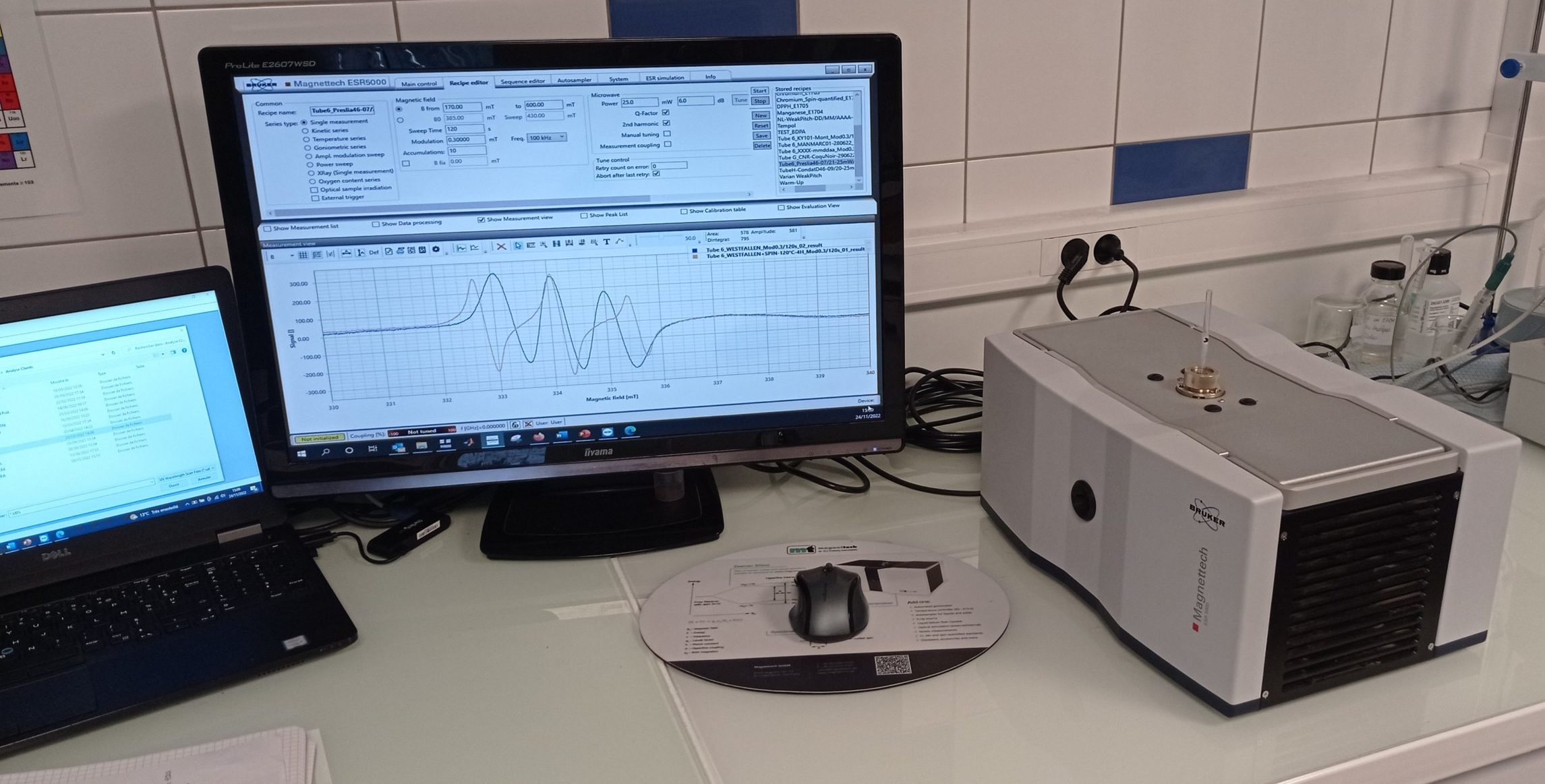

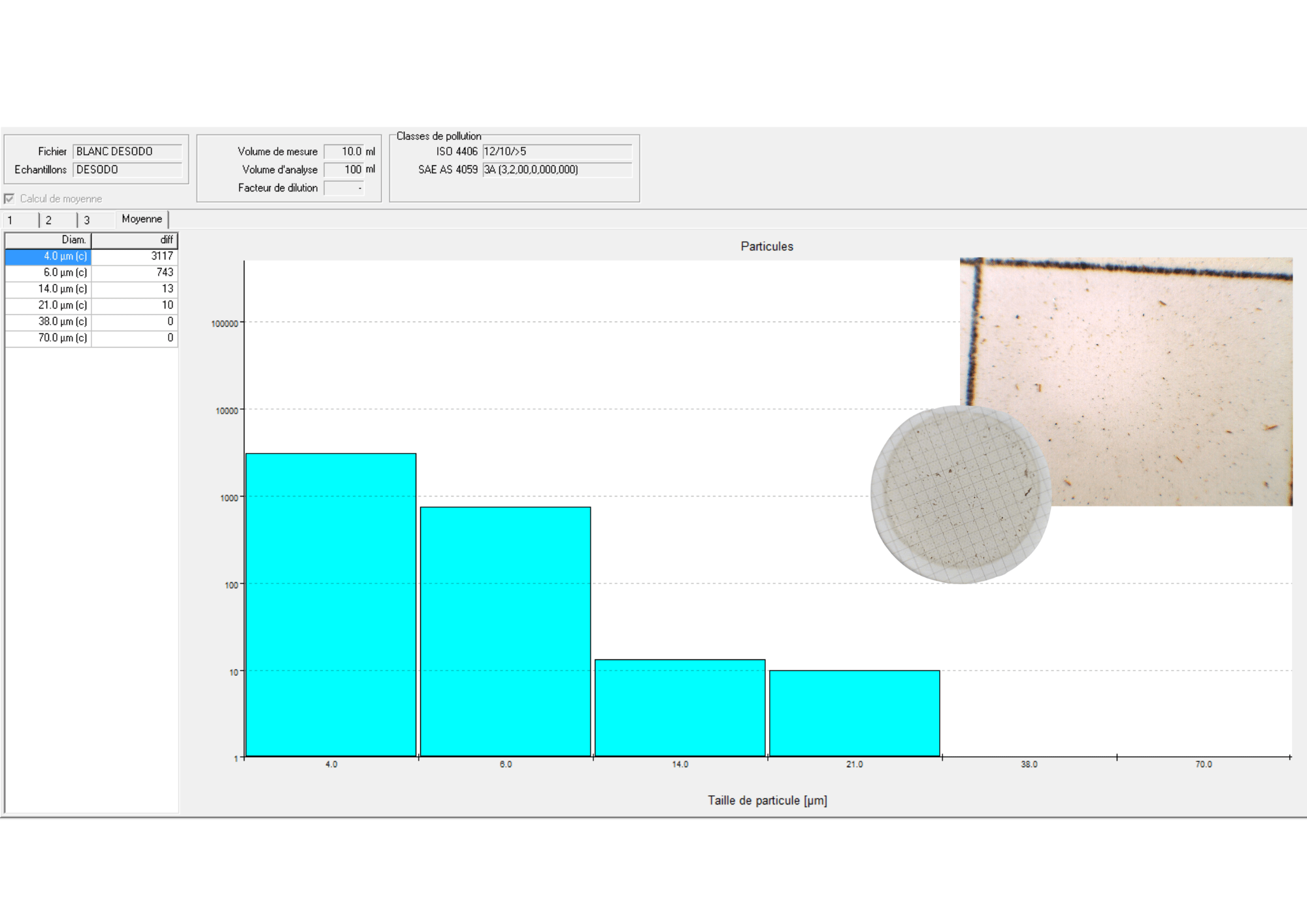

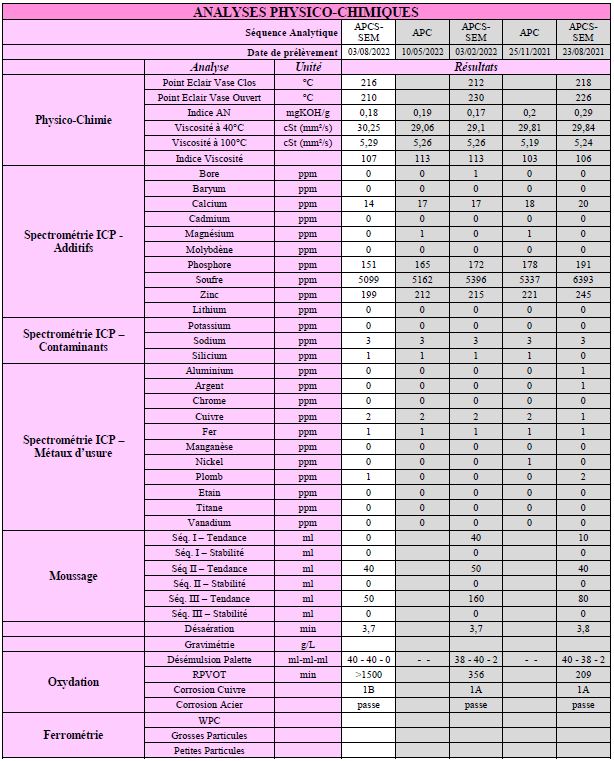

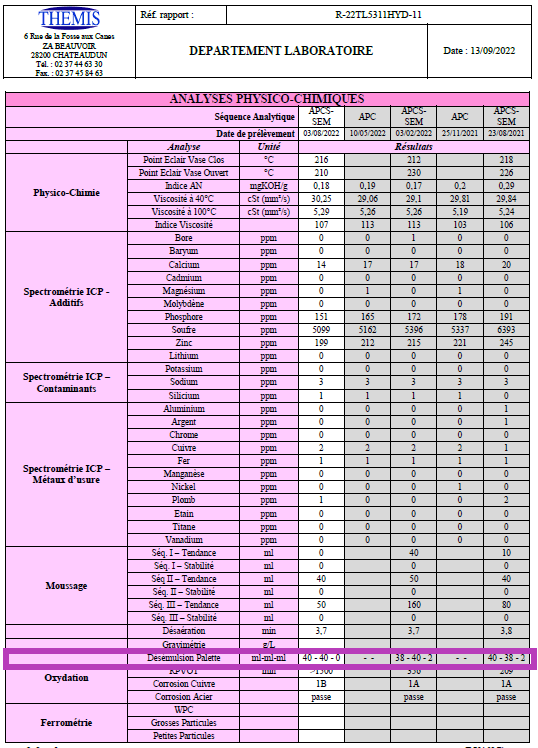

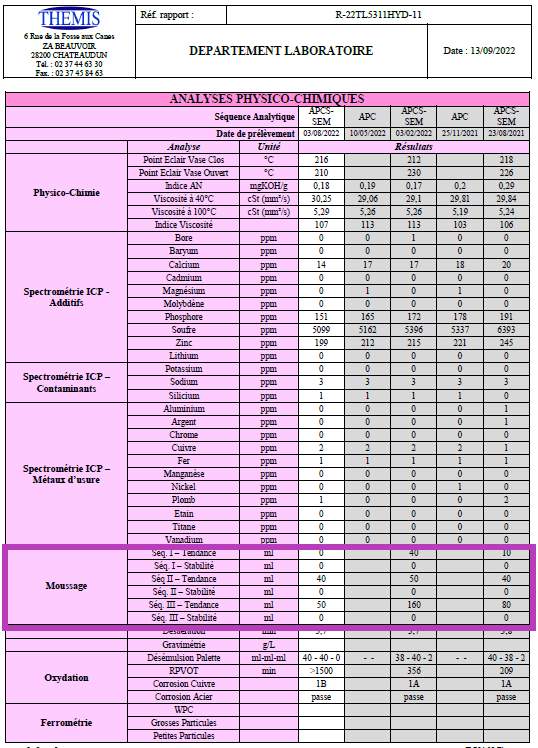

The award-winning project is based on a non-destructive EPR technology developed in partnership with French universities and the CNRS. This unique system detects the early signs of degradation in industrial oils, enabling technical problems to be anticipated before they occur. Thanks to this innovation, THEMIS enables industrial companies to optimize the lifespan of their equipment and prevent costly breakdowns.

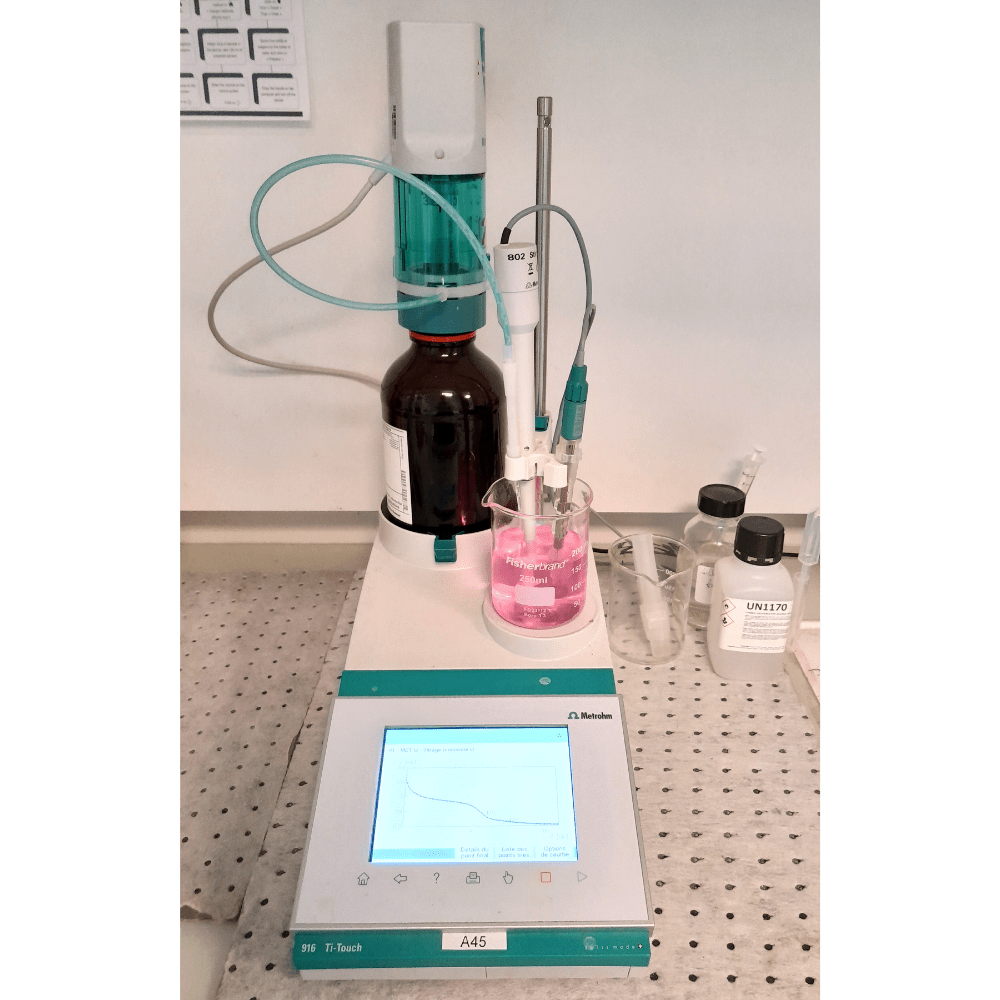

THEMIS Filtration, part of the Antara Groupe, won the Prix de l'Innovation 2024 at this year's Trophées des Entreprises. The Châteaudun-based SME specializes in hydraulic cleanliness, offering state-of-the-art filtration solutions for hydraulic and industrial oils. The award, presented to Marie ROUCAN, Head of THEMIS's Research Laboratory, crowns several decades of technological innovation and collaborative research.

A unique research project in the world

THEMIS Filtration has combined technological expertise and scientific collaboration to design this unique innovation. This new technology revolutionizes the treatment of industrial oils by enabling continuous and precise monitoring, thus anticipating any deterioration that may affect machine performance.

#Innovation2024 #HydraulicCleanliness #AntaraGroupe #BusinessAwards #IndustrialTechnology #ResearchAndDevelopment #OilFiltration #EPR #RPE #CNRS #InnovativeIndustry #Varnish

Laurent Lefur, manager of THEMIS Filtration, explains:

"We have been innovating in oil treatment processes for over twenty years. Our collaborative project with the CNRS has enabled us to develop a technology that offers manufacturers an advanced predictive solution. We are proud to see our innovation recognized at such a prestigious level."

This major project required an investment of €550,000, supported by the Antara Group, and has attracted the attention of the international scientific community. The technology has already been the subject of several publications and presentations at world congresses, with a forthcoming paper scheduled for Washington.

Jérémy Pallas, Director of Research and Development at THEMIS Filtration, adds:

"Understanding oil degradation better has opened new doors for us, and this innovation enables us to make predictions for our customers. We also hope, in the next few years, to be able to set up a plant dedicated to new materials."

- Posted in ANTARA GROUPE, International, New technologies

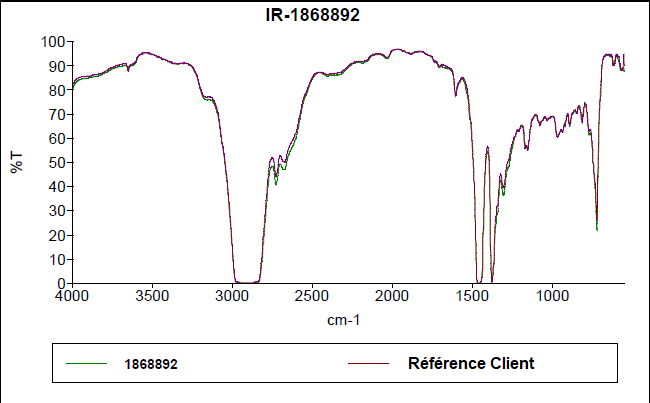

Dive into the world of oil aging tests

- Posted in ANTARA GROUPE, International, New technologies

ANTARA GROUPE guest on BFM Business! To talk about oil and fuel innovation

- Posted in ANTARA GROUPE, International, New technologies

CRNS THEMIS: Fundamental research on the degradation and reactions of OILS and FUELS

- Posted in ANTARA GROUPE, International, New technologies

- 1

- 2