Case study – Underground tanks: fuel decontamination using Antara® mobile skids

"Regain control over the quality of stored diesel fuel, without entering the tank, without hydrocleaning, without stopping operations."

An operator uses several 30–35 m³ underground tanks to supply trucks and machinery. For several months now:

- Repeated clogging of filters

- Injector failures

- Power losses

- Operational shutdowns

- Overuse of filters

The suspected cause: increasing contamination of underground tanks and distribution systems.

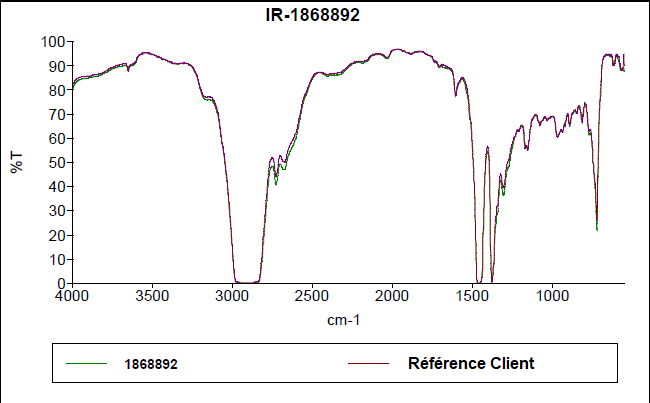

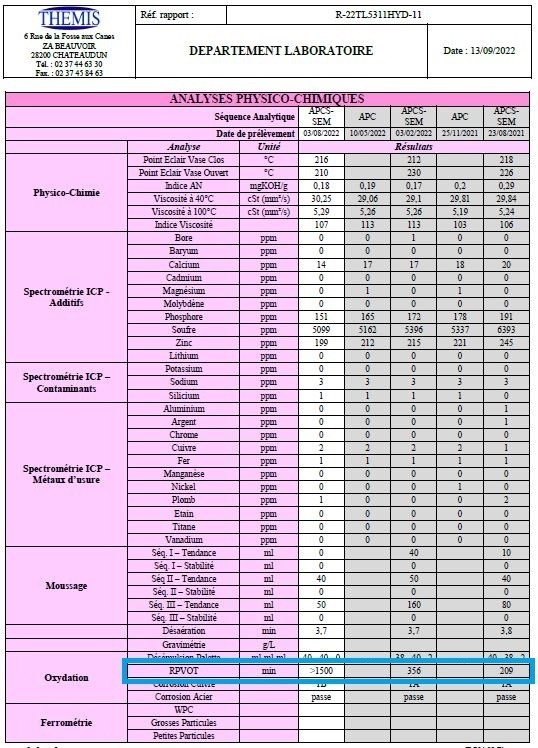

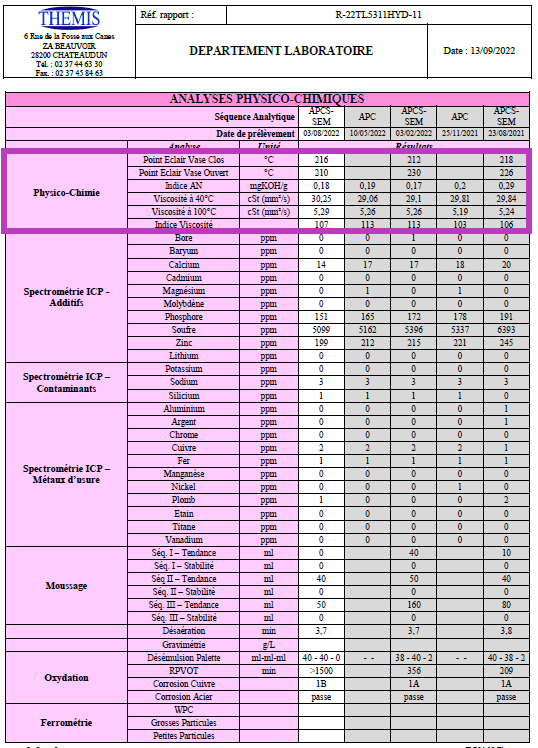

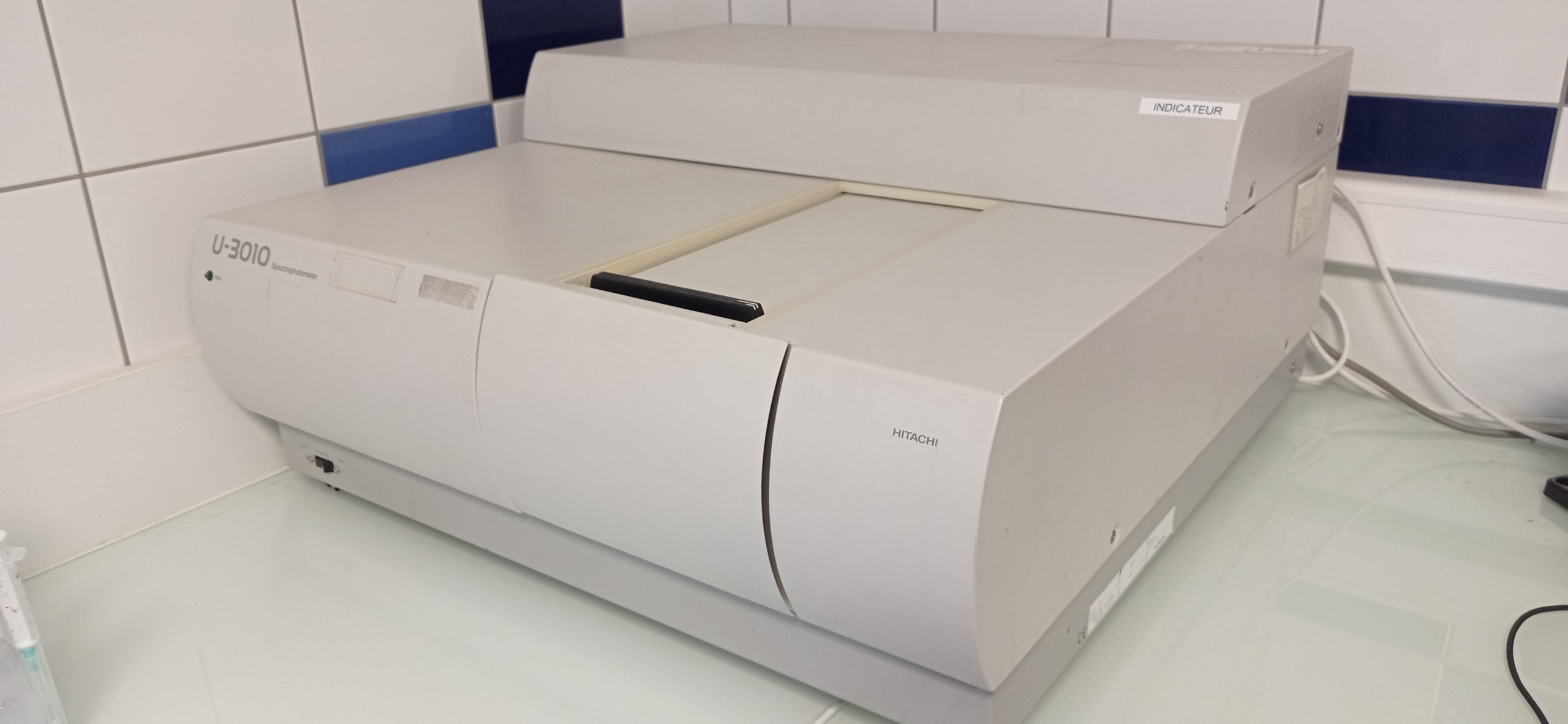

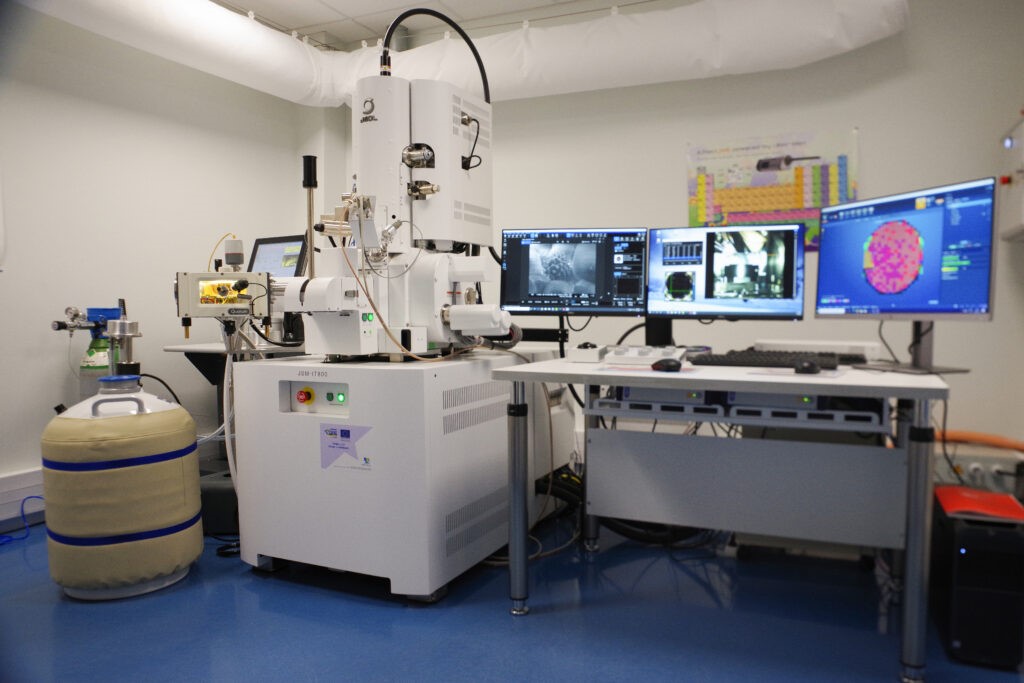

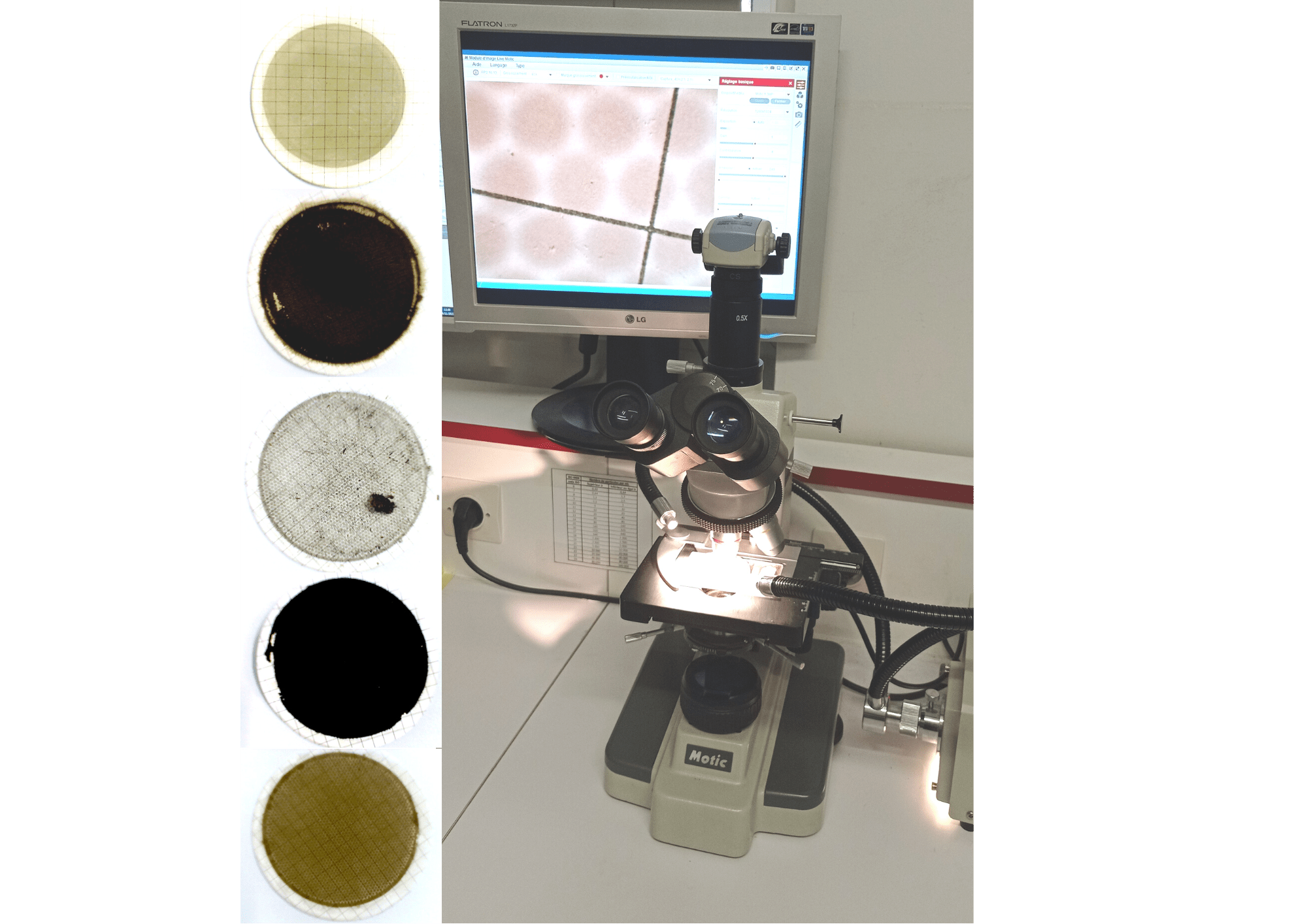

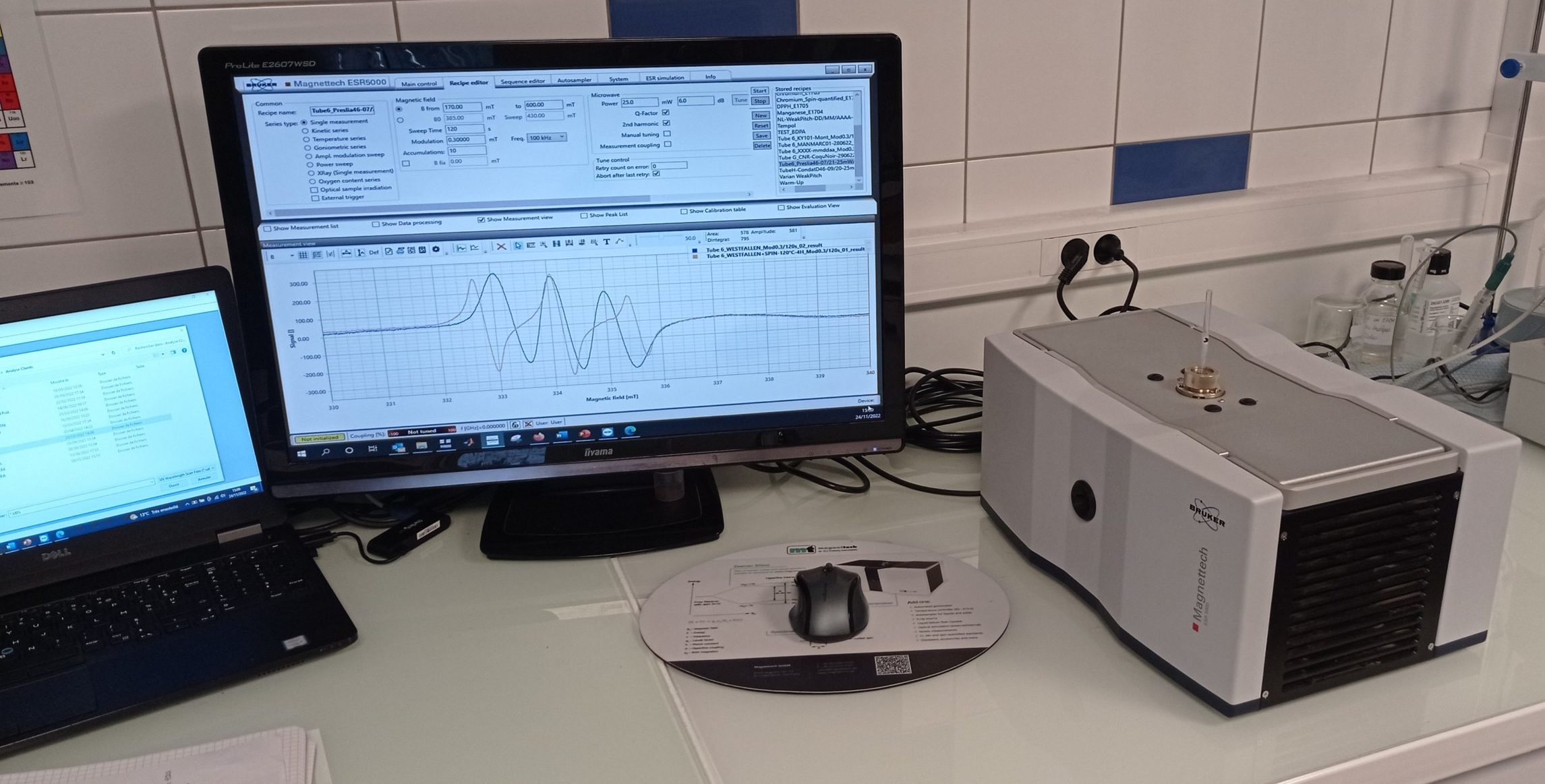

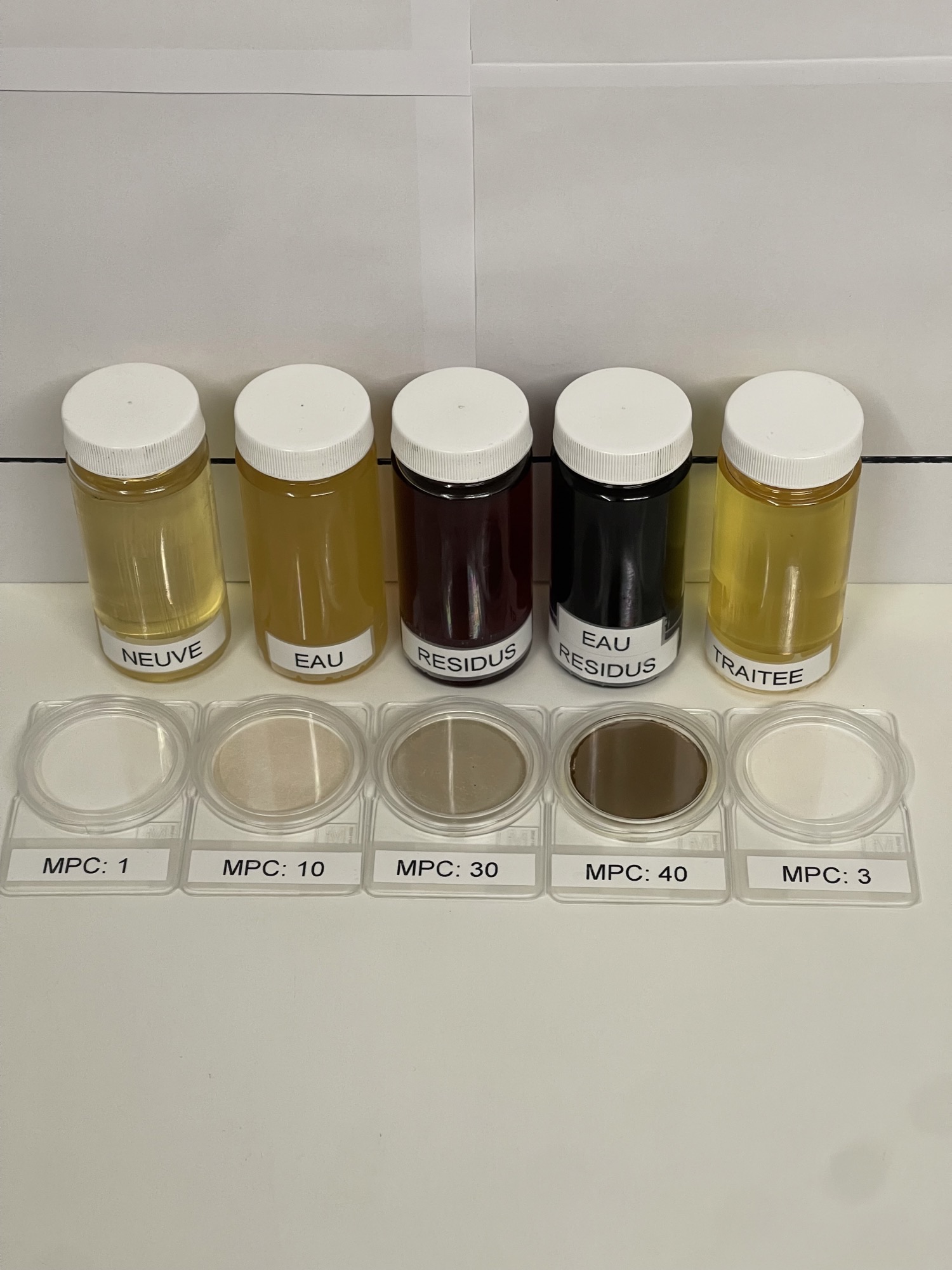

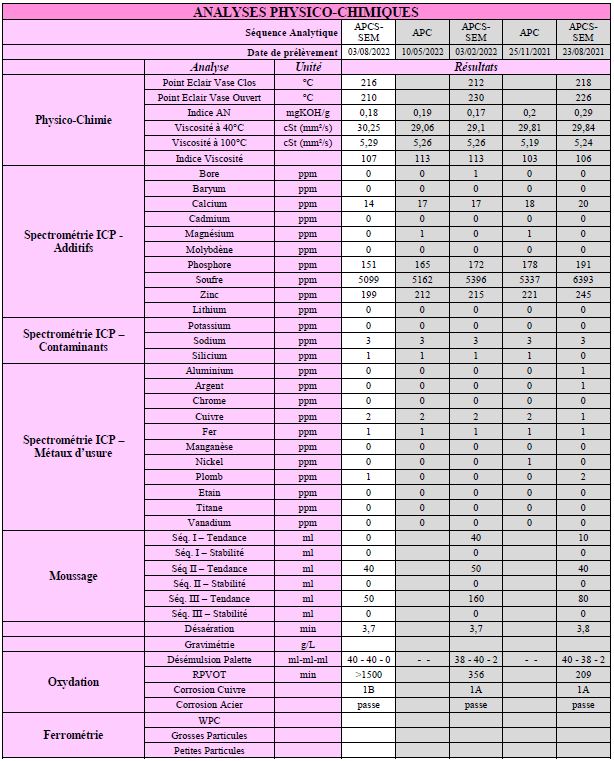

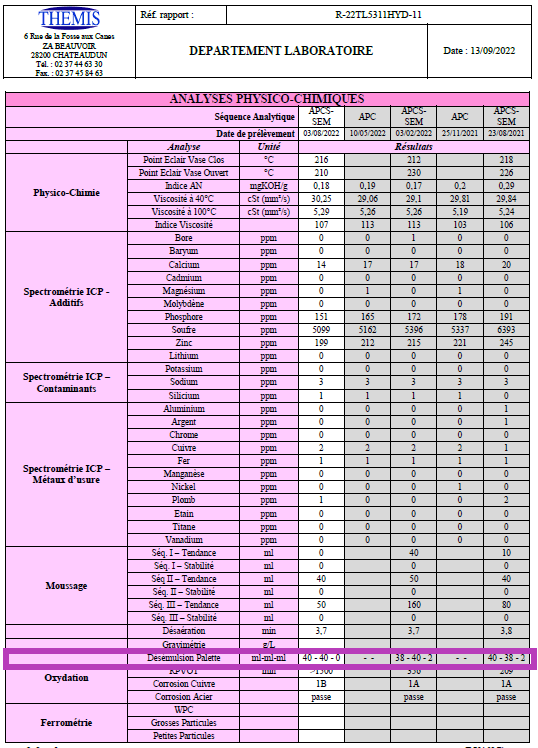

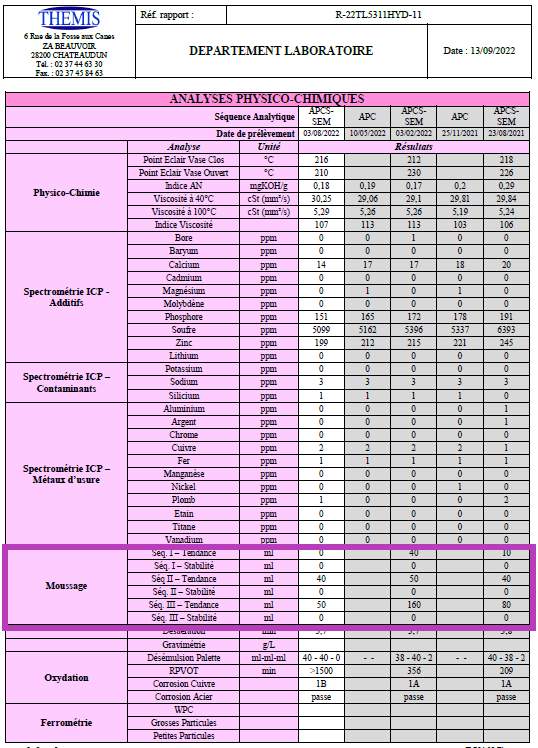

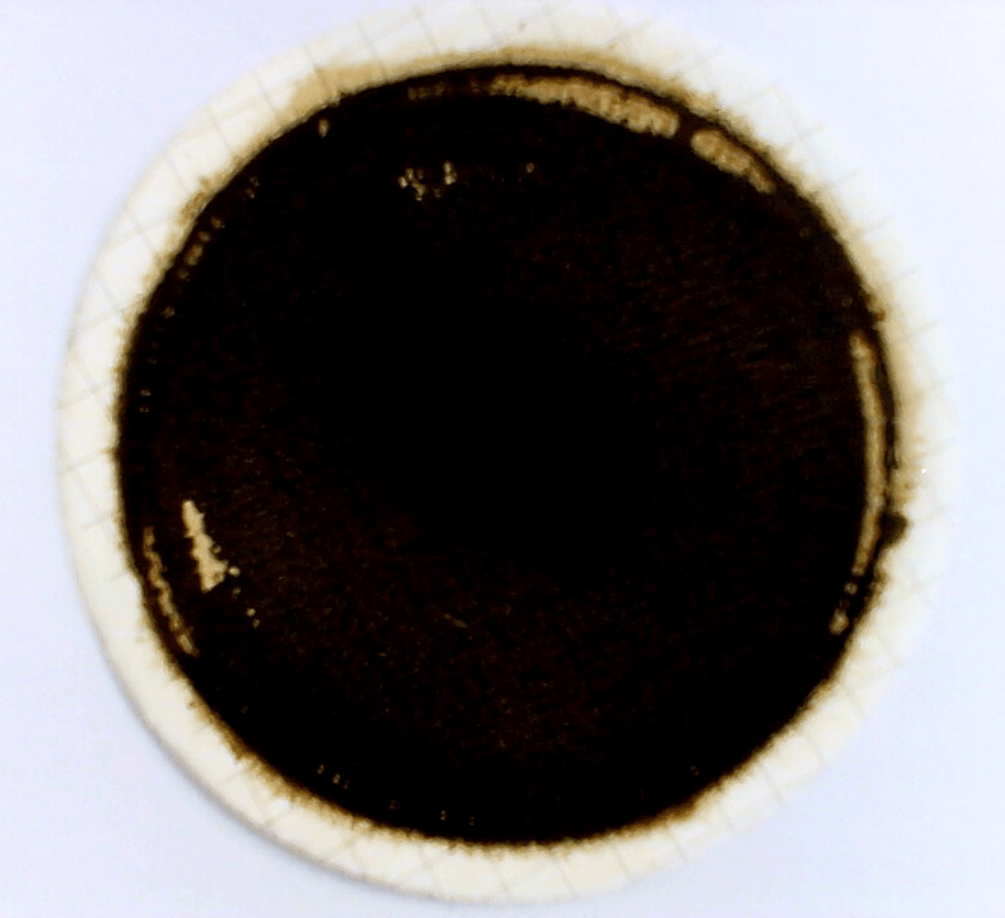

A series of analyses is carried out on the distribution outlet and in the underground tanks.

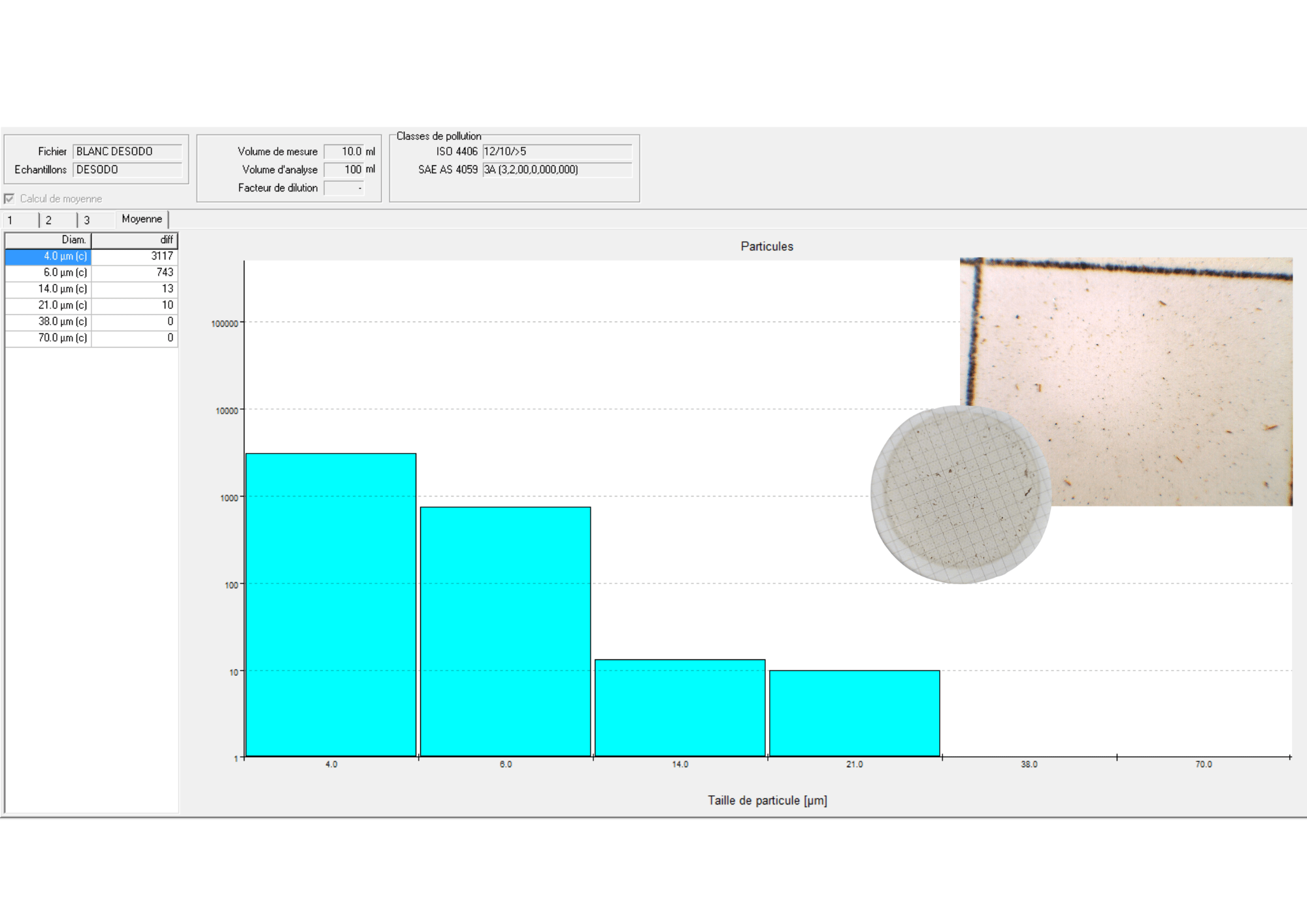

- High presence of particles and debris

- Presence of free water in the tank (risk of corrosion, bacteria, and fuel degradation)

- ISO 4406 code before treatment: 23/22/20 (excluding truck injection specifications)

- Distribution already contaminated when leaving the nozzles

The distribution system is also contaminated. When it leaves the nozzle, the fuel still contains particles, which cause filter clogging and injector failure.

- Dedicated in-line filtration on distribution

- Recirculation via mobile skid, without stopping operation

- Reduction in fuel quality-related incidents

Result: clean and stable distribution.

Restore fuel quality to meet injection requirements, without draining tanks, without heavy hydrocleaning, without entering tanks, without stopping operations.

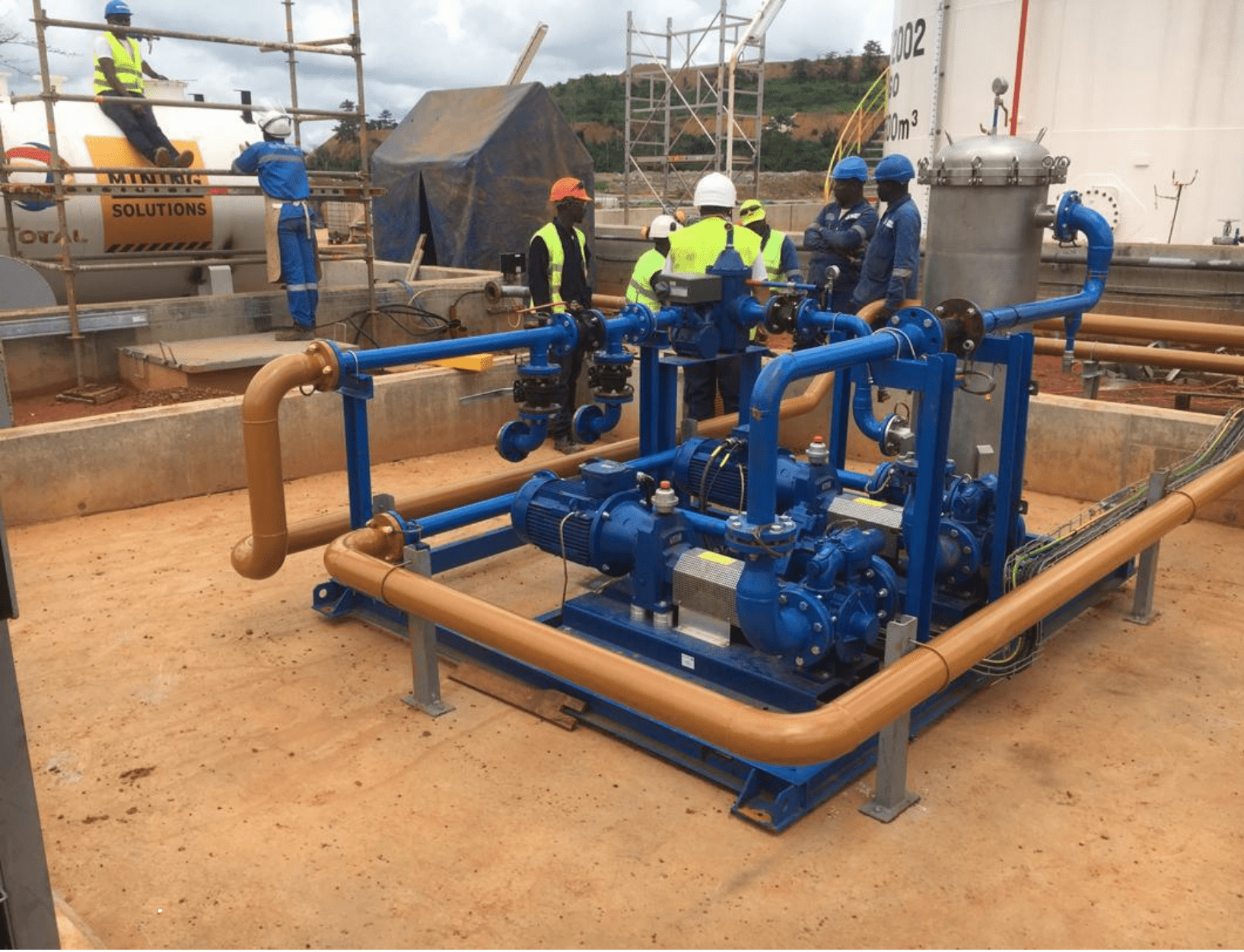

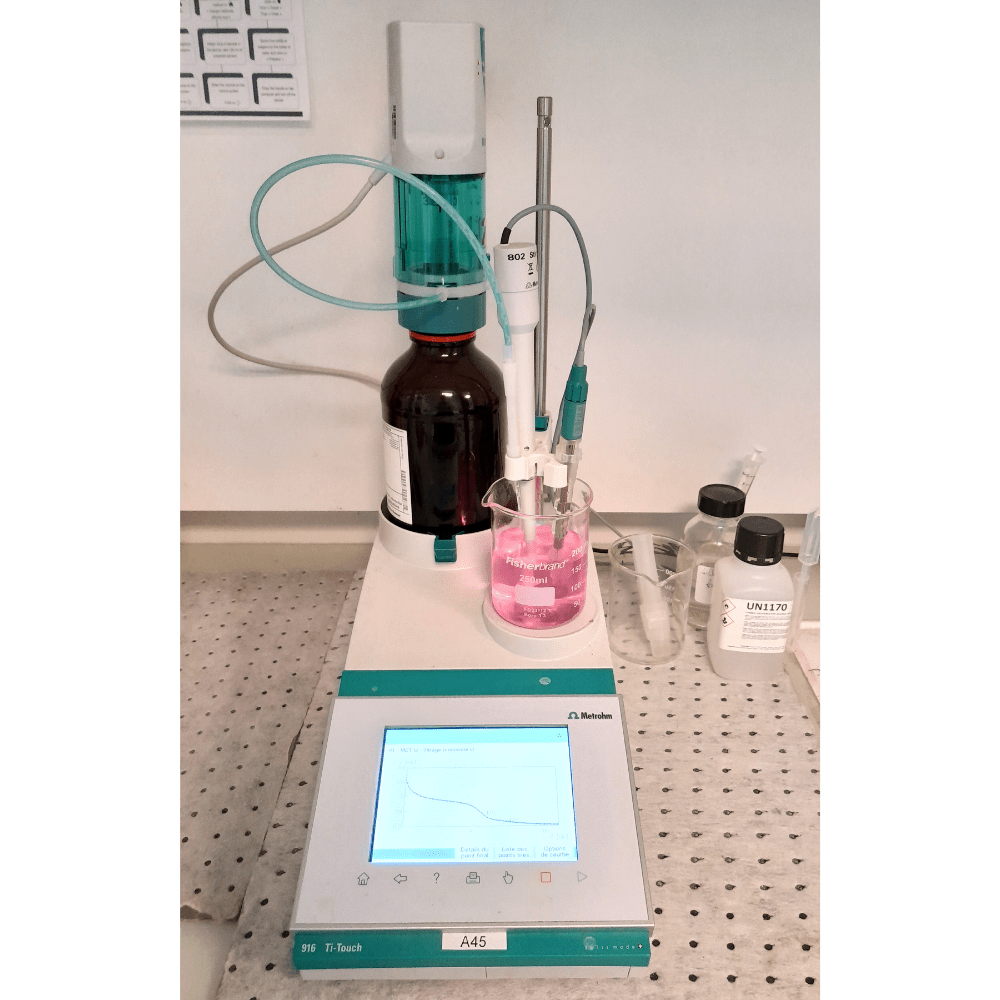

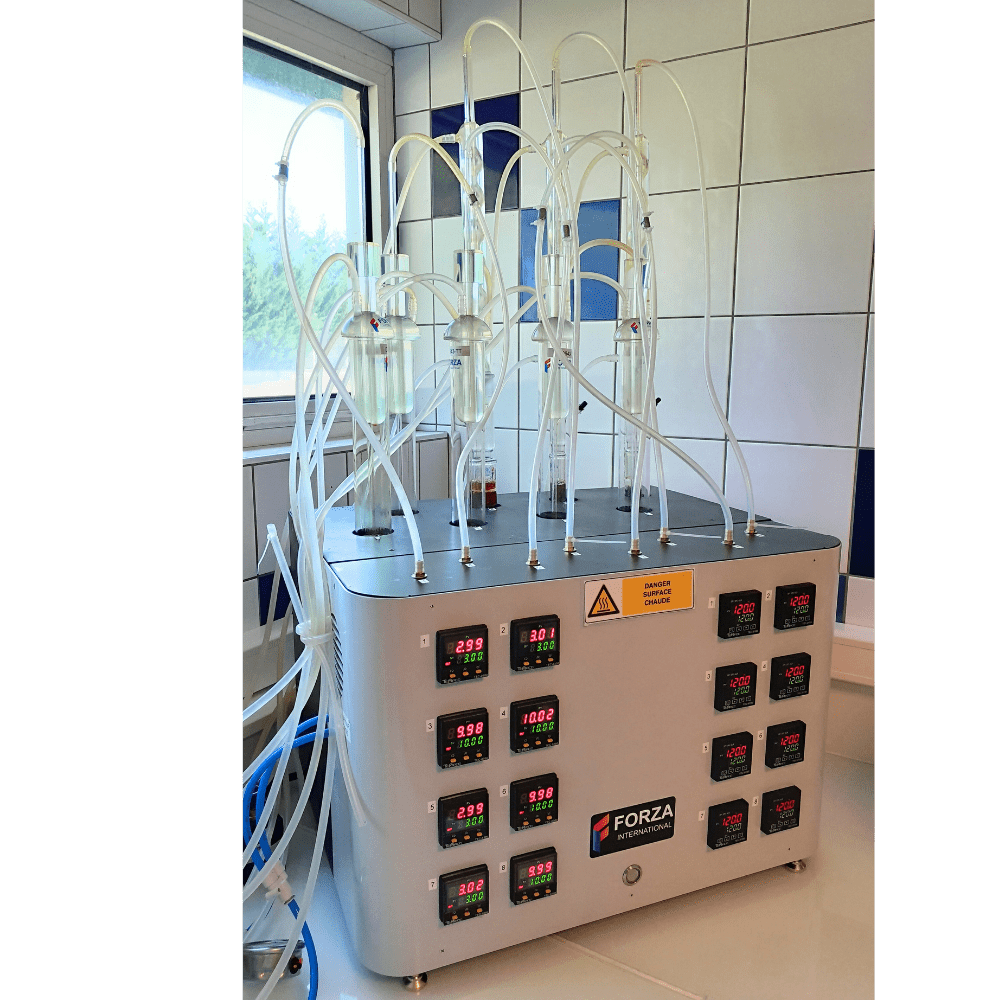

Antara® mobile skid deployed to successively decontaminate tanks and secure distribution.

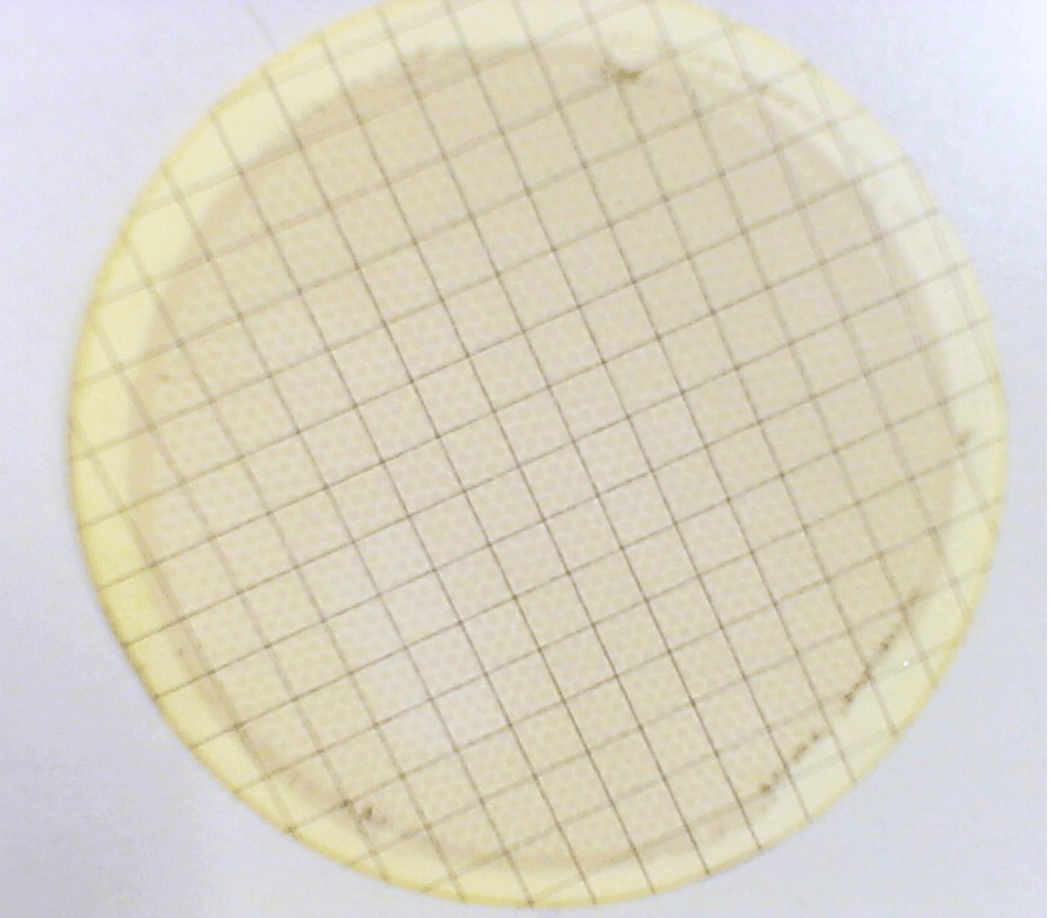

- Hybris®: high-efficiency filtration of fine particles

- Calista®: water separation/filtration in a single pass (free water)

- Closed-loop recirculation without human input

- ≈ 58 min of treatment on the most critical tank

- ISO 4406 code after treatment: 17/15/12 (injection class)

- Elimination of off-peaks and stabilization of fuel quality

- No fuel drain

- No site downtime

- Traitement total < 0,5 journée

Comparison of available options for treating pollution in underground tanks:

| Criterion | Heavy hydrocleaning | Competing mobile solutions | Antara® mobile skid |

|---|---|---|---|

| Draining fuel | Yes | Often | No |

| Cessation of operations | Yes | Sometimes | No |

| Human entry into tanks | Yes (high risk) | Limited | No |

| Open water treatment + particles | Partial | Variable | Complete (Hybris® + Calista®) |

| Final quality ISO 4406 | Not guaranteed | Variable | 17/15/12 |

Antara® mobile skid – Underground tank decontamination

"Clean tanks without entering them, without hydrocleaning, without interruption."

To explore our other configurations (fixed skids, multi-tank solutions, continuous polishing), check out our Antara® fuel decontamination solutions .

www.antara-groupe.com