Antara Groupe

Case Study – Critical Lubricants: Oil Degradation Invisible to Standard Analyses

European Refinery – Turbines & Compressors

Advanced diagnostics (APH membranes / ESR) and Antara solution (AUGEO OIL + TRO Dual system – oil regeneration )

Operator: Large European refinery operating a turbine and two critical process gas compressors.

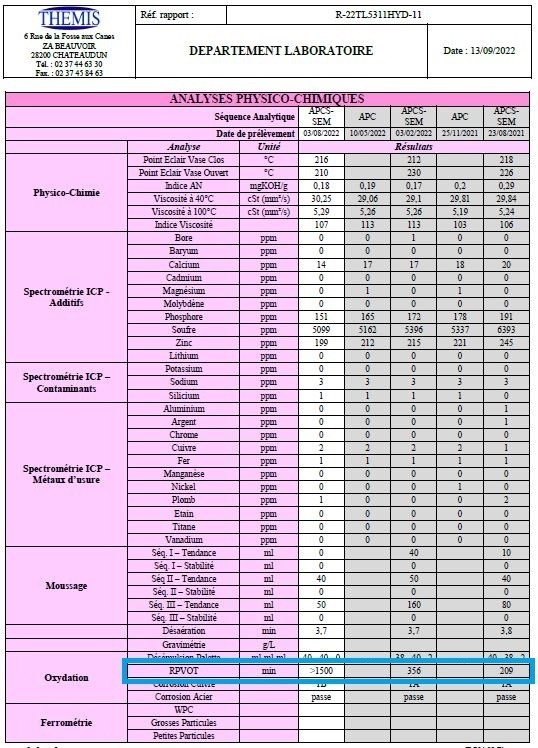

Issue: ISO code drift from 17/16/15 to 20/17/15, initially misinterpreted as particulate contamination.

Internal analyses: MPC = 8, parameters considered acceptable → initial recommendation for a full oil-system flushing.

Objectives: Identify the real root cause, characterize lubricant degradation by-products, avoid heavy flushing, and leverage a reusable case study for other units.

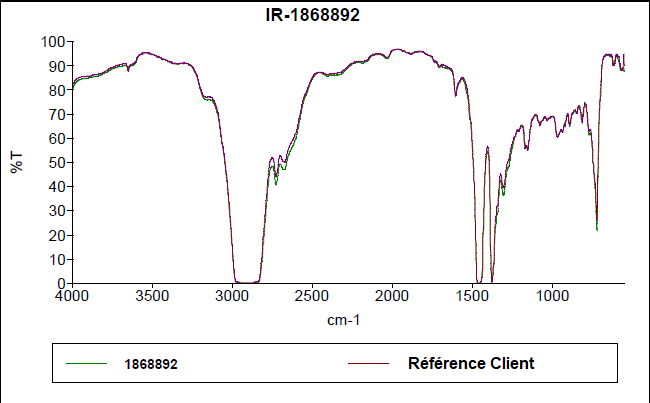

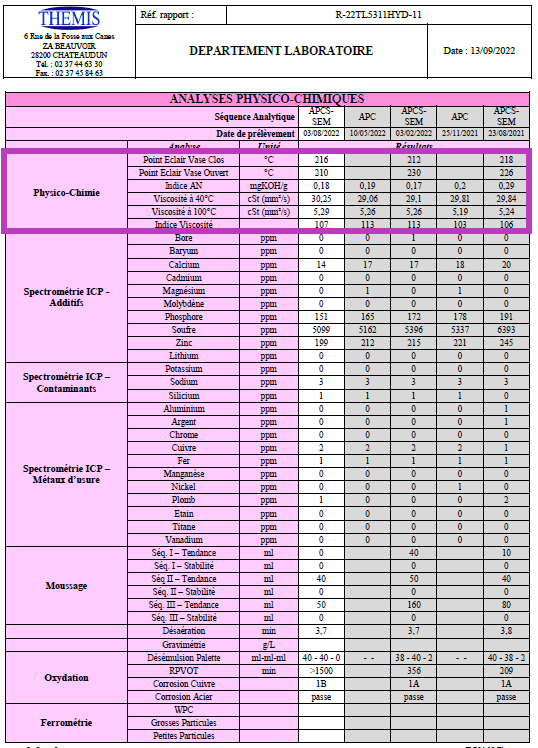

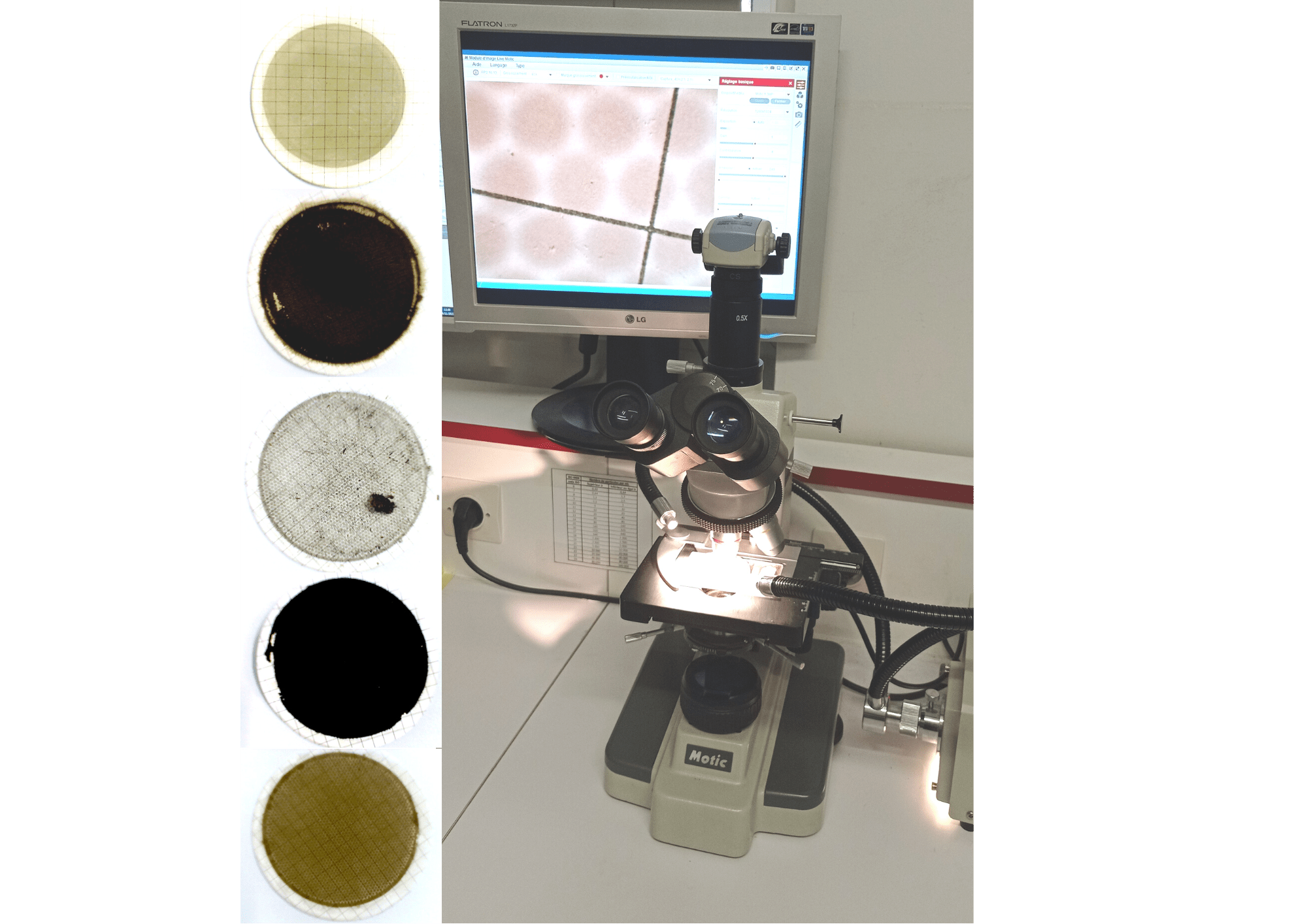

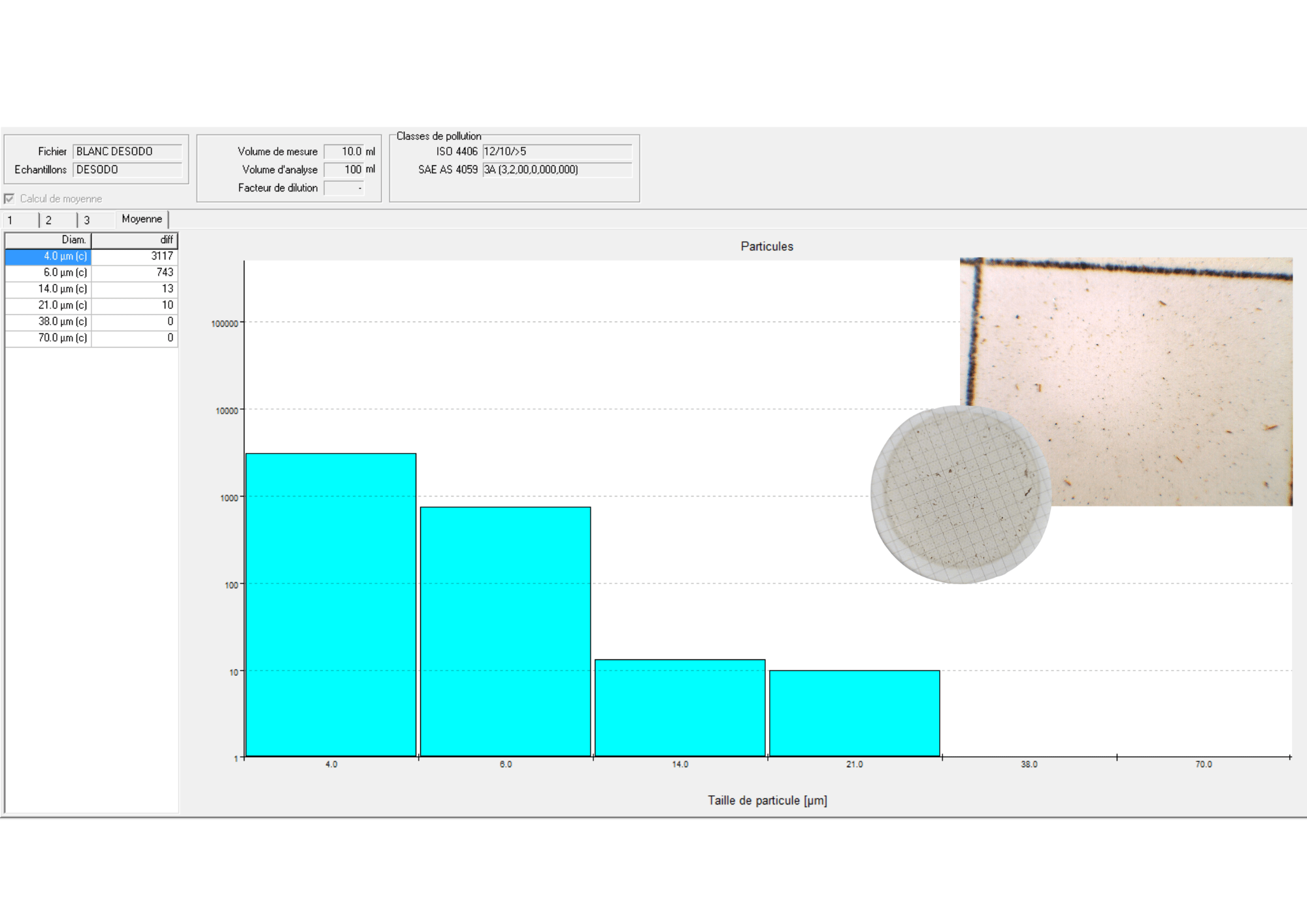

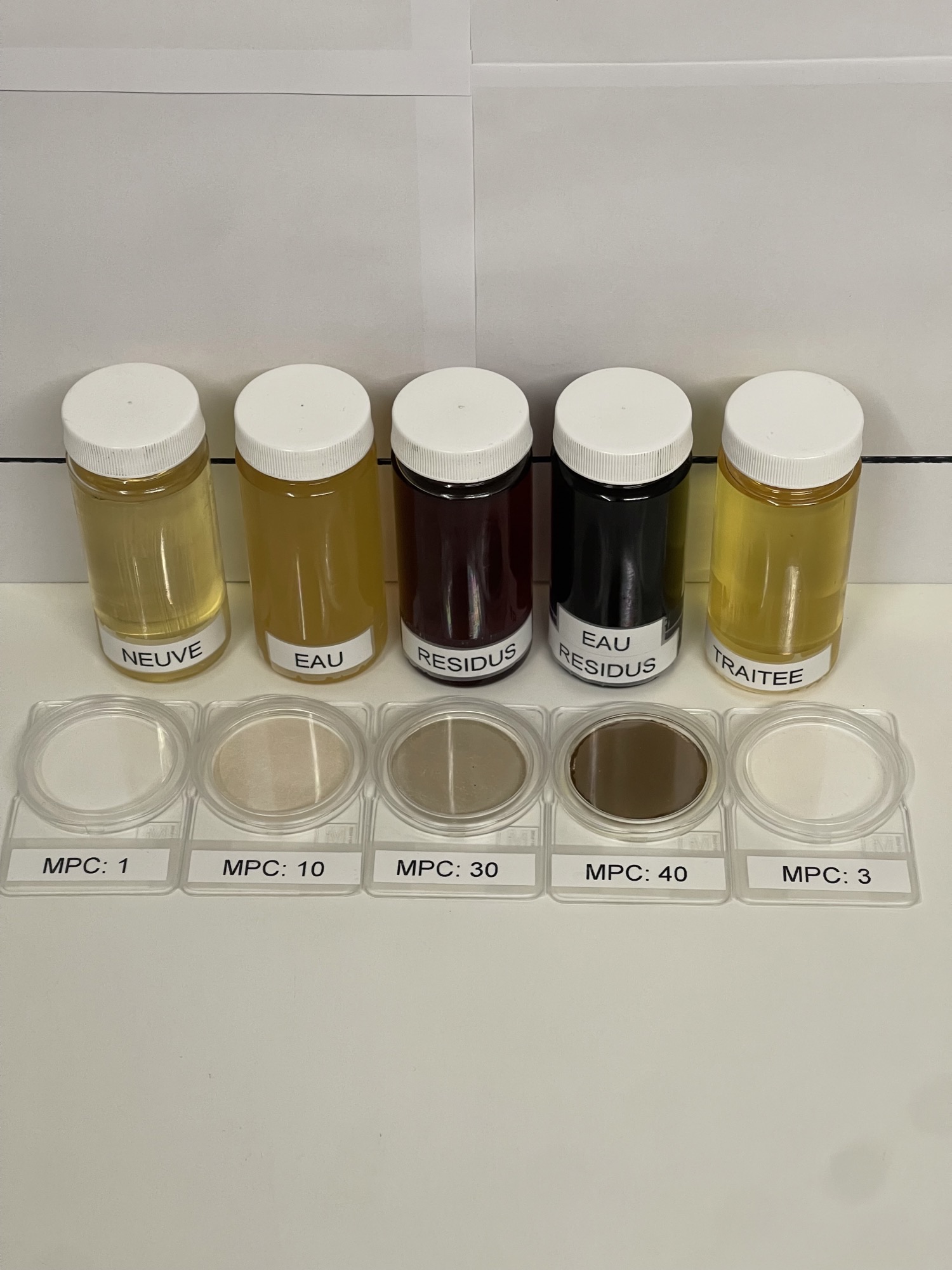

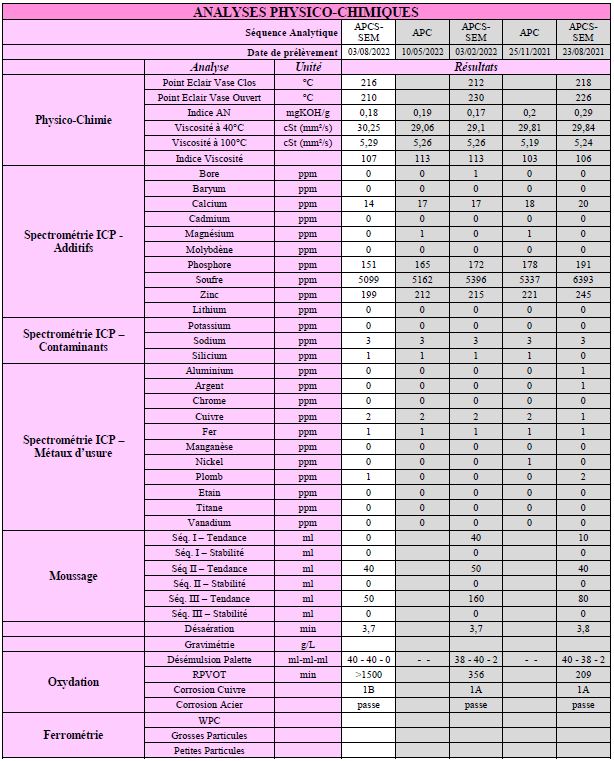

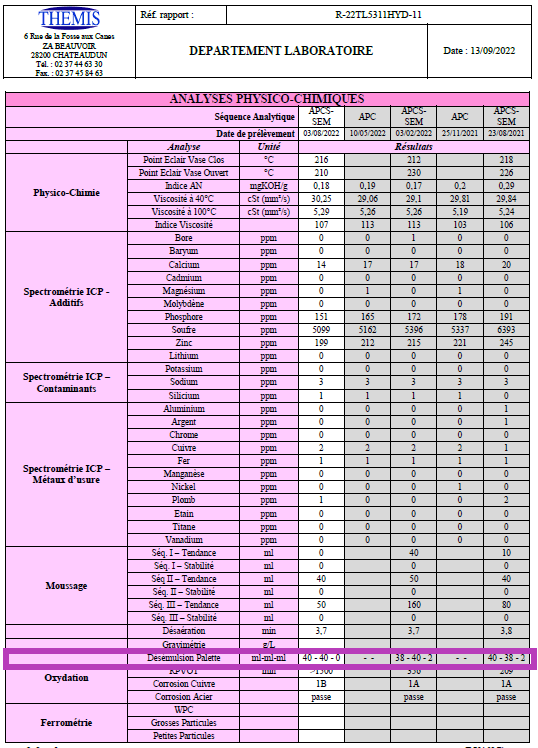

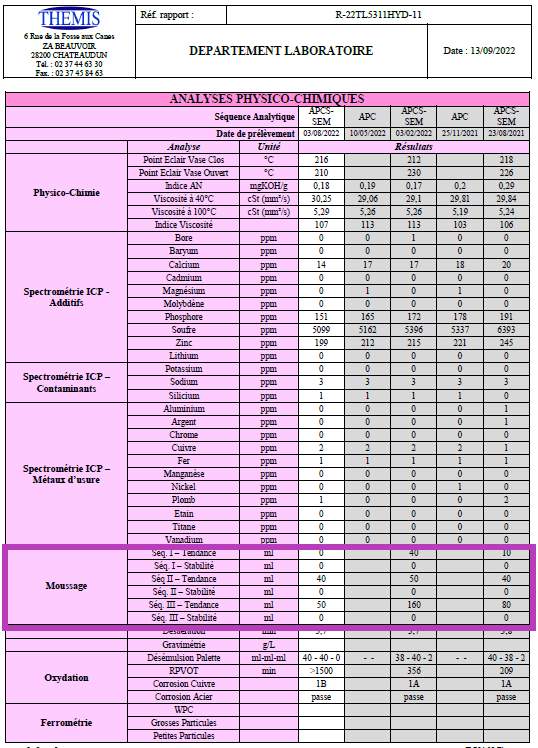

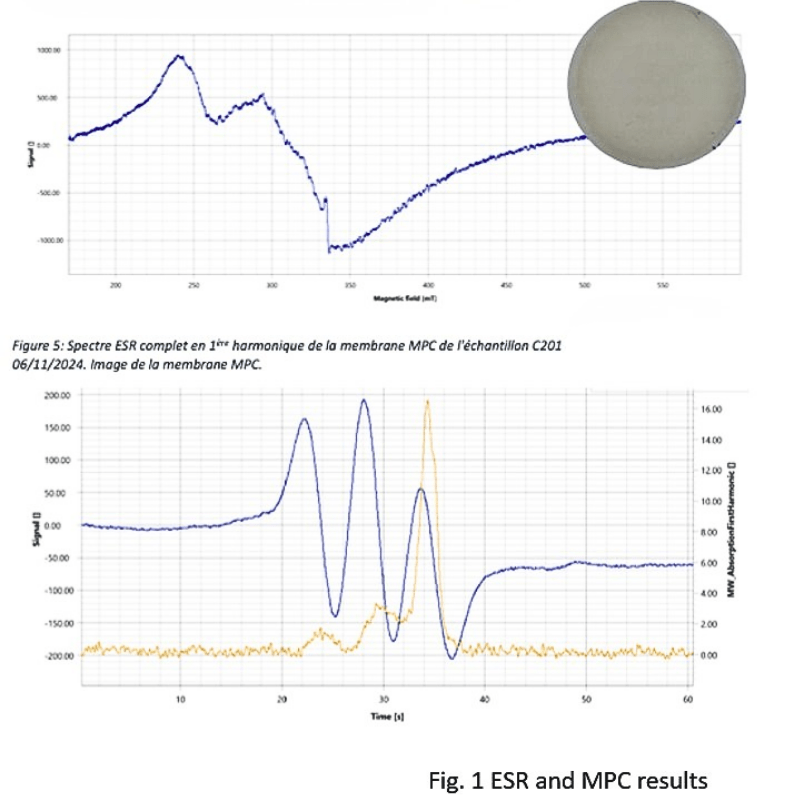

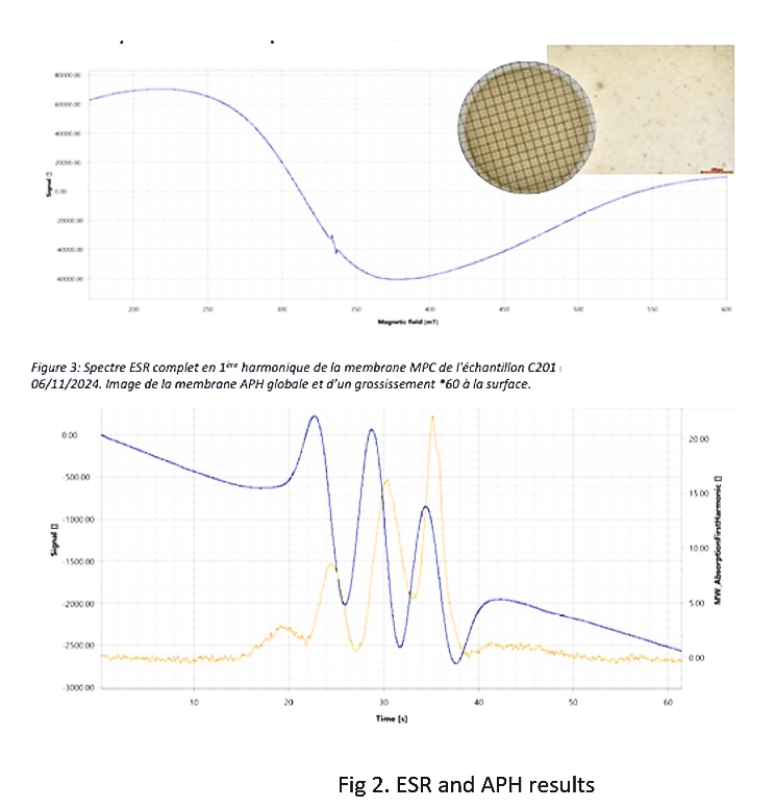

MPC vs APH membranes: revealing polar degradation products

- MPC = 8 → deemed satisfactory.

- APH membranes (0.8 µm, more polar) → strong retention of degradation products.

- Brown–orange, crystalline & gel-like deposits on the APH membrane.

- Resins and polar compounds underestimated by standard MPC evaluation.

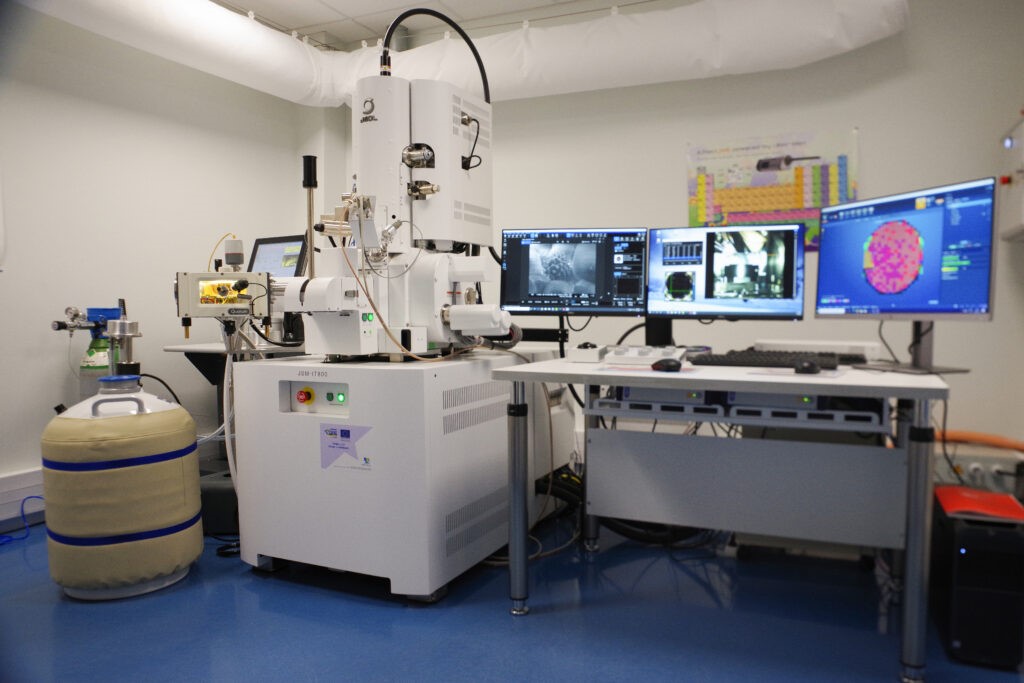

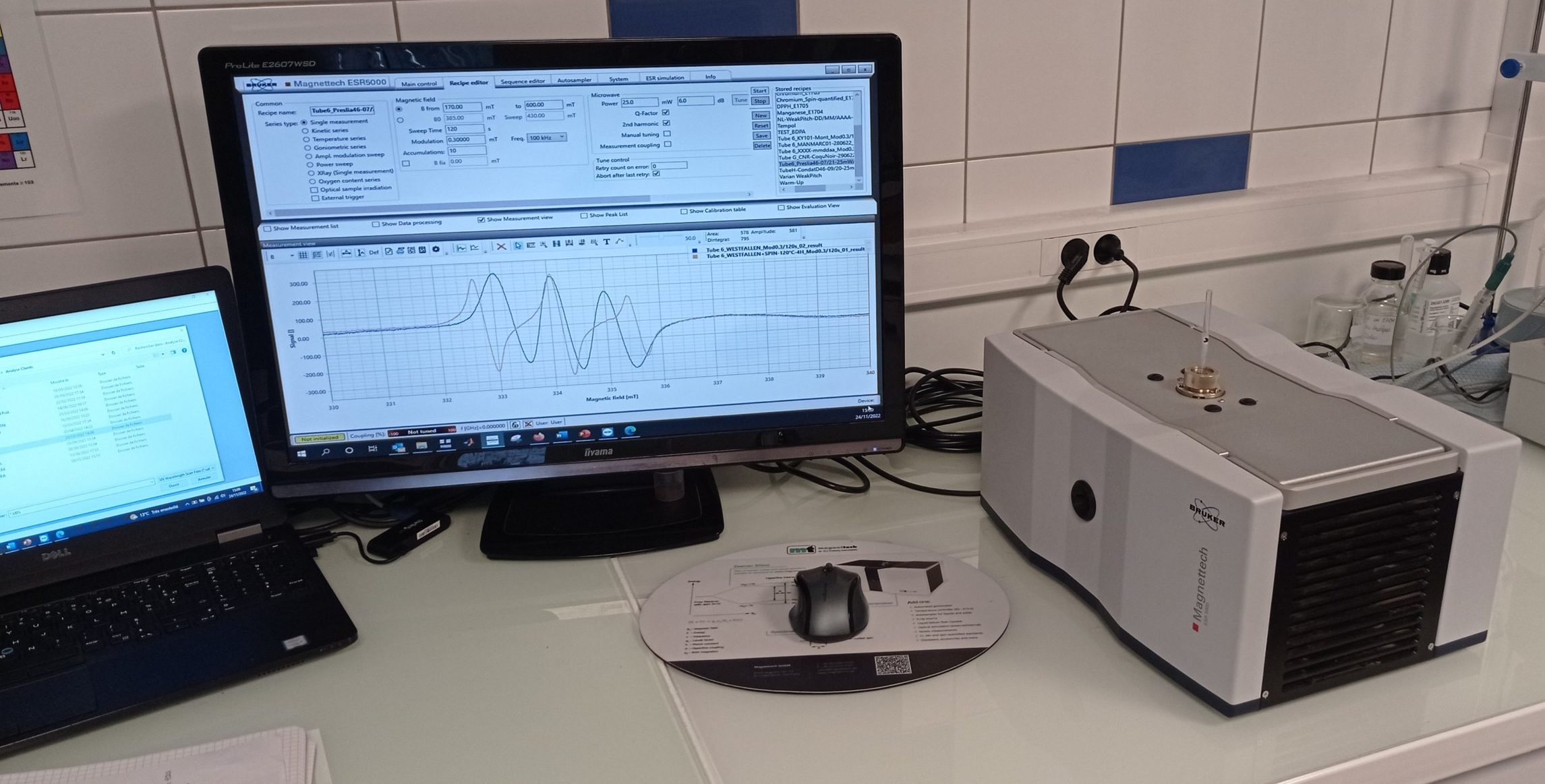

Aminyl radicals & copper complexes

- Aminyl radicals: advanced degradation of amine antioxidants.

- Copper complex detected by ESR but not visible by ICP (ppb-level presence).

- Confirmation of a copper alloy in the circuit, acting as a catalyst for radical reactions.

AUGEO OIL – targeted cleaning

- Solubilization of polar degradation products and resins responsible for deposits.

- Cleaning internal deposits in the turbine and compressors.

- Neutralization of the most reactive degradation species.

This curative phase restores a clean and stable baseline before implementing continuous regeneration with TRO systems.

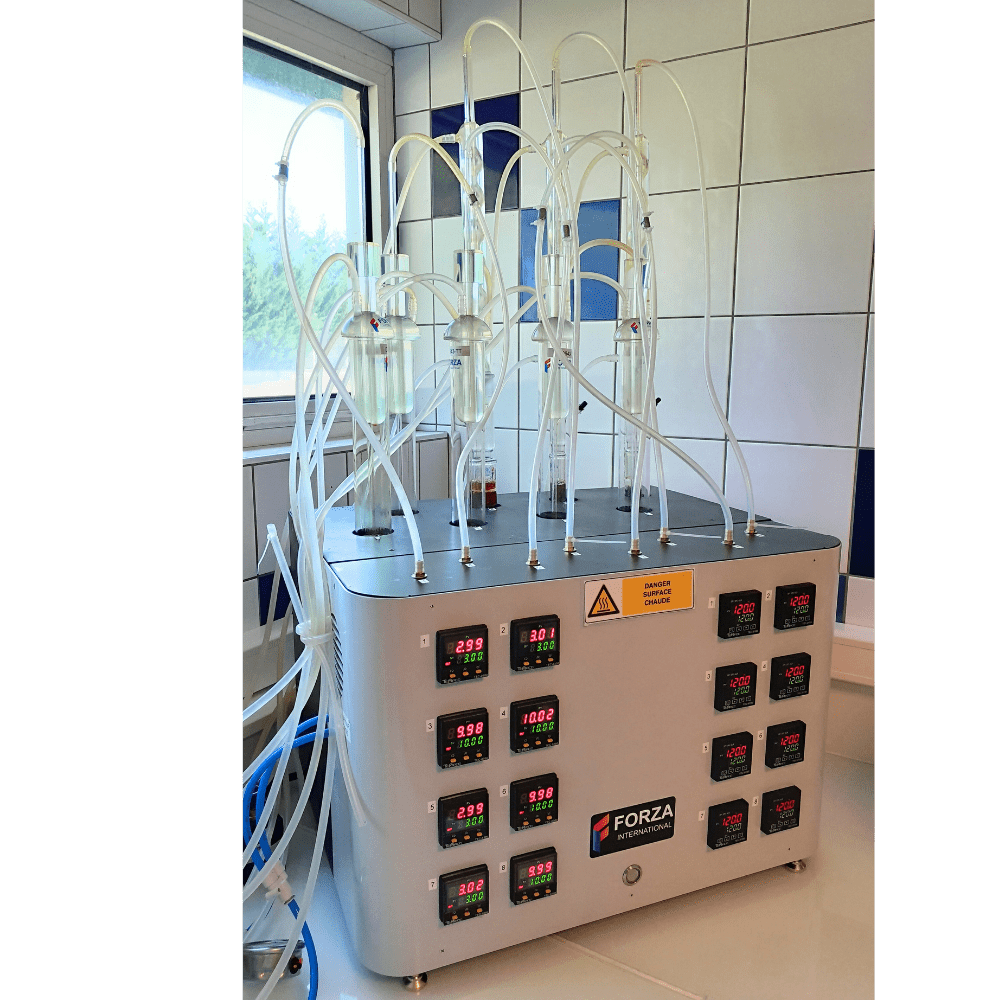

Continuous regeneration with the TRO Dual system

- Continuous removal of polar degradation products and their precursors.

- Reduction of radicals that accelerate oil oxidation.

- Limitation of catalytic effects from trace copper species.

- Long-term stabilization of the lubricant and its antioxidant package.

The operator shifts from one-off treatments to a proactive oil health management, leveraging the Antara TRO Dual system.

- Significant reduction of resinous and gel-like deposits in the oil system.

- Long-term stabilization of the antioxidant package and lubricant chemistry.

- Improved ISO cleanliness without performing a full flush.

- Longer oil life and reduced consumption.

- Increased availability of critical turbines and compressors.

Benefits for the operator

- Fewer unplanned stops related to lubrication issues.

- Stabilized operational performance on critical equipment.

- Secured operational continuity, independent of supply chain disruptions.

Benefits for maintenance and reliability

- Full flushing avoided (time, budget, and risk savings).

- Reduced corrective interventions on the oil system.

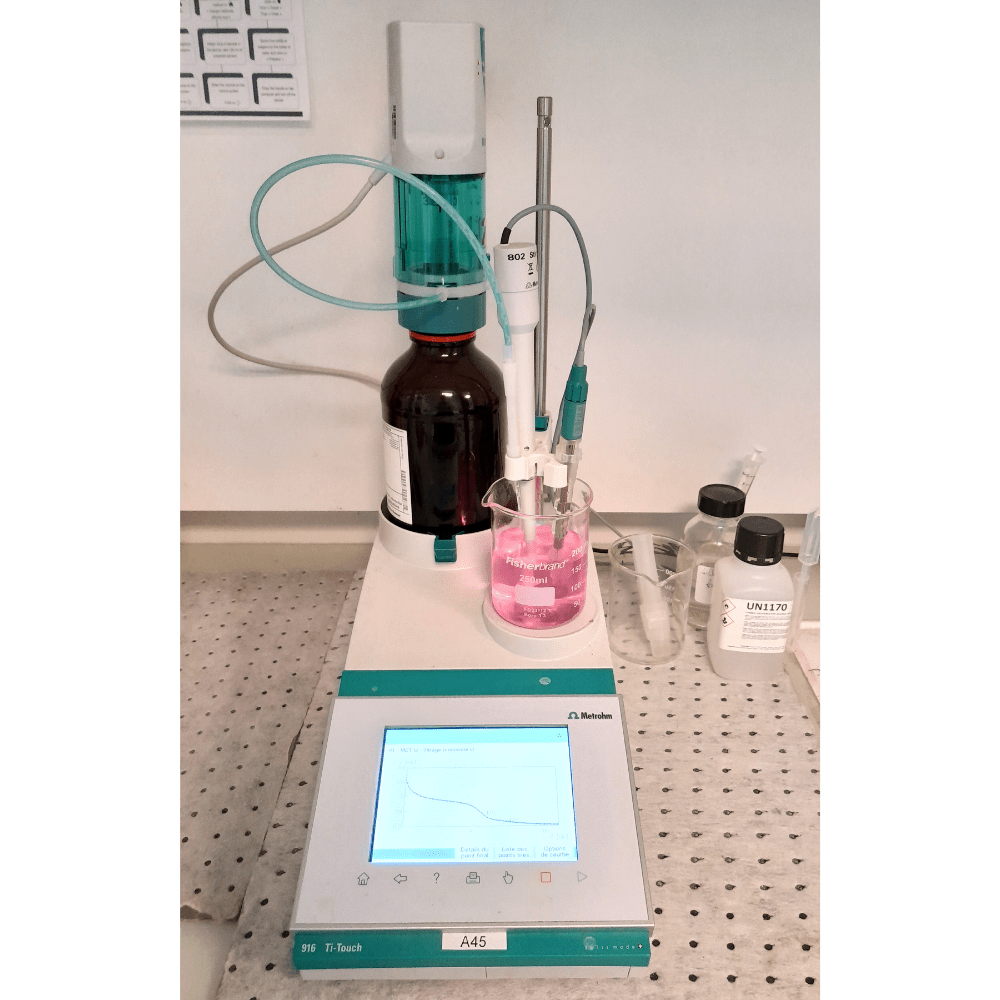

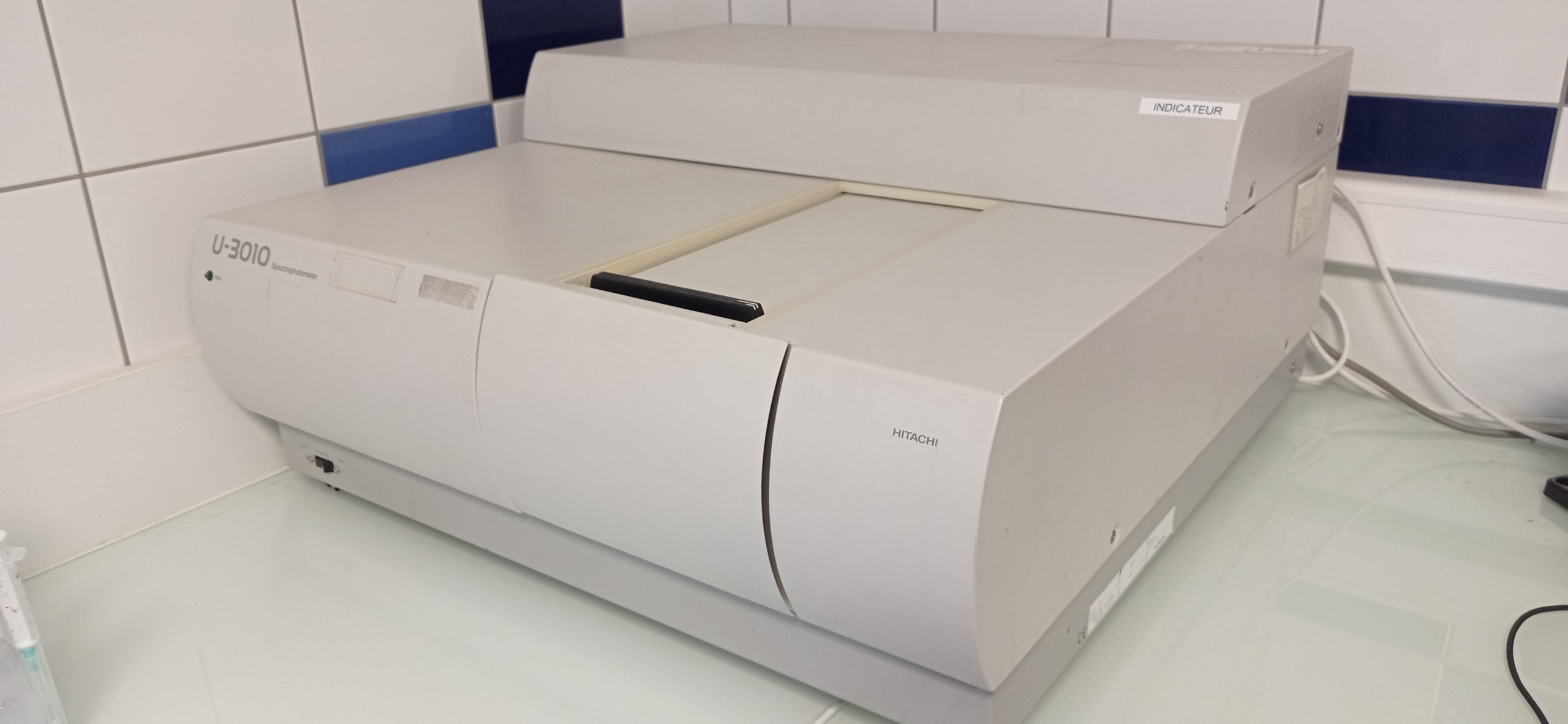

- Team capability upgrade through advanced diagnostics (APH membranes, ESR).

The combined approach AUGEO OIL + TRO Dual system addressed the true root cause (polar compounds, resins, radicals, copper catalysis) without requiring a full flushing. This methodology illustrates Antara’s ability to support sensitive installations, secure long-term oil health, and deploy a sustainable strategy applicable to similar units.

Applicable to turbines, compressors, hydraulic systems, and critical oil circuits.

Antara Group specializes in advanced lubricant diagnostics in refineries and heavy industry: APH membranes, ESR analysis (Electron Spin Resonance), identification of polar compounds, resins and free radicals, antioxidant package stabilization, AUGEO OIL technologies, TRO Dual systems and continuous regeneration of industrial lubricants for turbines, compressors, tanks and complex oil circuits.